(1603 products available)

Scaffolding staircase are temporary staircases used to access elevated work areas. They are a type of scaffolding that provides safe and easy access to different levels of a construction site. Scaffolding staircases are a vital component of any scaffolding system, allowing workers to move safely between different levels of a work site. There are different types of scaffolding staircases which include:

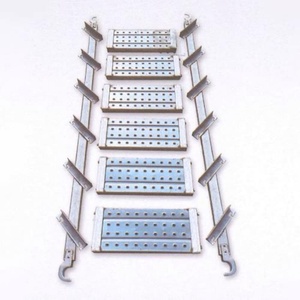

Scaffolding staircase are constructed with stability in mind. They are made from durable materials such as steel or aluminum, which can support the weight of users and equipment. The design of the staircase also ensures stability. For example, the treads and handrails are well spaced to provide a firm grip and balance for users. Some scaffolding staircases have adjustable legs that can be extended to level the staircase on uneven surfaces, which further enhances stability and safety.

The portability of temporary scaffold staircase makes them suitable for construction sites. They can be easily assembled and disassembled for transportation. Most scaffolding staircases have lightweight frames constructed from aluminum, making them easy to move from one location to another. They also have wheels attached to the base frame, which allows users to push them to the desired location instead of carrying them. The wheels can be locked to prevent movement when the staircase is in use.

Scaffolding staircase are versatile in the applications they can be used for. They can be used in different industries, such as construction, manufacturing, and warehousing. The staircases come in different designs, such as straight, L-shaped, or U-shaped, which allows them to be used in different environments. They also have adjustable heights that can be customized to fit different working heights. Domestic stairwell scaffold are also compatible with different types of scaffolding systems, which increases their usability.

Scaffolding staircases are constructed with safety in mind. They have slip-resistant treads that provide a firm grip to prevent users from falling. The treads are also perforated to allow water and debris to pass through, which minimizes the risk of slipping. The staircases have handrails on both sides that users can hold onto for balance. Some models have guardrails that surround the entire staircase to prevent falls. The handrails are padded to provide a comfortable grip.

Scaffolding staircases are designed to be easy to assemble. They come with detailed instructions that guide users on how to put them together. Many parts, such as handrails and treads, are pre-assembled at the factory, which reduces the time and effort needed to set up the staircase. The individual components are also designed to fit together easily, which eliminates the need for special tools during assembly.

Construction workers often use staircase scaffold to access higher levels of work areas. These are perfect for use in construction and renovation projects. They provide safe and easy access for workers and materials to be transported between levels, improving productivity and efficiency on the job site.

Building owners and maintenance crews use cuplock staircase to perform routine maintenance and repairs on tall structures. These allow easy access to hard-to-reach areas for tasks such as window washing, painting, and repairing exterior surfaces.

Event planners and concert organizers use it to set up stages and structures for outdoor events and concerts. It provides a stable and safe platform for workers to build stages, lighting rigs, and other event infrastructure.

They are used in emergency situations where quick evacuation is needed from high-rise buildings. Firefighters and rescue workers use them to help people safely descend from tall buildings during fires or other emergencies.

Bridge construction crews use it to build and repair bridges and overpasses. These provide a safe way for workers to access and work on the tall structures needed for bridge construction, such as support beams and spans.

Maritime and aviation industries use it to perform maintenance on ships and aircraft. They provide access to hard-to-reach areas of planes and ships for tasks such as painting, repairing, and cleaning.

Telecommunications and utility companies use it to install and maintain communication towers and power lines. It allows workers to safely access the tall structures needed for installing and repairing equipment and lines.

Film and television production crews use it to build sets and lighting rigs for on-location shoots. It allows for the creation of complex sets and scenes that require elevated platforms.

They are also used in outdoor recreation activities, such as rock climbing and zip-lining. They provide elevated platforms for activities that require heights and safety measures.

When choosing a scaffolding staircase for purchase, there are several factors a customer should consider. These include safety concerns, the intended use of the scaffolding staircase, and the features of the scaffolding staircase that would enhance its functionality. Below is a comprehensive breakdown of the factors one should consider to make an informed decision when buying a scaffolding staircase:

Q1. How do you stabilize a scaffolding staircase?

A1. To keep the scaffolding stairs stable, secure both the top and bottom using outriggers or guardrails. Also, make sure to secure the stairs to the scaffolding with a chain or gate.

Q2. How often should scaffolding stairs be inspected?

A2. Scaffolding stairs and support systems should be inspected before first use and periodically, usually weekly, by a competent person. They should also be inspected after any event that could affect their structural integrity, such as a fall or strong wind.

Q3. What is the ideal rise and run for a scaffolding staircase?

A3. The ideal rise is between 150 and 170 mm, while the ideal run is between 280 and 300 mm. The ideal slope is between 30 and 35 degrees. These measurements ensure the stairs are safe and comfortable to use.

Q4. What are some common safety features of scaffolding stairs?

A4. Safety features can include handrails, non-slip treads, and guardrails. Many scaffolding stairs also have safety gates that open only in one direction.

Q5. What tools are needed to assemble scaffolding stairs?

A5. The tools needed can vary but often include a wrench, hammer, and drill. A socket wrench set and Allen wrenches are also commonly used. Some sets may require an impact wrench for assembly.