All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(359 products available)

Sandwich panel 5 cm is a prefabricated building material consisting of three layers: two outer sheets (usually made of metal) and a core layer (which is often foam for insulation). These panels are commonly used for roofing and walls in various constructions because they are lightweight, insulated, and quick to install. They provide structural integrity and weather resistance for buildings.

These panels are popular in various industries, including construction, refrigeration, and transportation, due to their strength, lightweight properties, and excellent thermal insulation. Here are some common types:

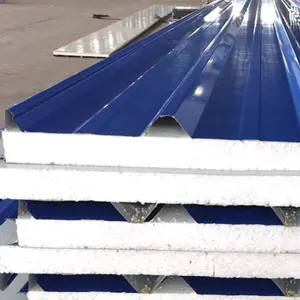

EPS Sandwich Panel

The EPS (Expanded Polystyrene) sandwich panel is a cost-effective choice for construction projects. It consists of two metal sheets, usually steel, and an expanded polystyrene foam core. EPS panels are popular for use as walls and roofs in buildings such as warehouses, workshops, and commercial structures. They are known for their lightweight properties, structural strength, and thermal insulation.

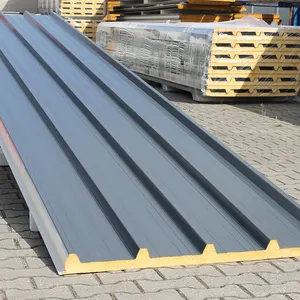

Rock Wool Sandwich Panel

This type of panel is made of steel sheets and a core of rock wool (stone wool) insulation. Rock wool panels are excellent for fire resistance because rock wool can withstand high temperatures without melting. They provide good thermal insulation and are commonly used in industrial buildings, cool storage facilities, and structures requiring fire safety.

PU Sandwich Panel

The Polyurethane (PU) panel is a popular choice for buildings that require high thermal insulation efficiency. It's made of steel sheets and a polyurethane foam core. PU panels offer superior insulation because of the low thermal conductivity of polyurethane foam. They are commonly used in cold storage, refrigeration facilities, and energy-efficient buildings.

Glass Wool Sandwich Panel

These panels consist of steel sheets and a glass wool insulation core. They are lightweight, offer good thermal insulation, and are commonly used in non-load-bearing walls and roofs. They are also popular in commercial buildings and industrial facilities because of their acoustic properties.

Aluminum Honeycomb Panel

Aluminum honeycomb panels are made of aluminum sheets and a honeycomb-shaped aluminum core. They are very lightweight and provide high rigidity and structural strength. They are commonly used in interior applications, such as walls, partitions, and ceilings in airports, subway stations, and other large public places.

5 cm panels are usually used for building cold rooms, storage facilities, and warehouses. They can also store perishable goods. These panels help reduce the temperature and keep the items stored in the refrigerator or freezer safe.

These panels are also used in temporary site offices. The structural integrity of these offices is strong enough to house engineers, architects, and other professionals, depending on the project's size and scope.

Features:

5 cm thick panels are ideal for storage rooms, small kiosks, and cold rooms. They are also suitable for site offices, guard houses, and other temporary structures that require insulation.

Refrigerated Trucks:

Refrigerated trucks often use 5 cm insulated panels to build their containers. The panels provide enough insulation to keep perishable goods at the required temperature during transit.

Cooling Chambers:

Cooling chambers are large storage facilities with temperatures between 0-4 degrees Celcius. They store perishable goods in bulk before they are distributed. 5 cm insulated panels are ideal for building small and medium-sized cooling chambers.

Electrical Enclosures:

Insulated panels are used to build cabinets and enclosures for electrical components. The panels help to prevent overheating by dissipating heat. They also keep the electrical components safe from extreme temperatures and other environmental hazards.

Interior Partitions:

5 cm panels can be used to create insulated partitions within temperature-controlled spaces. For instance, in large-scale operations like meat or dairy processing, partitions can separate different processes or storage areas while maintaining distinct temperature requirements.

Modular Construction:

These panels suit modular construction techniques where transportable, pre-fabricated units are built off-site. Examples include modular cold storage units, pop-up restaurants, or portable medical facilities that require insulation and are easily assembled on location.

Temporary Structures:

5 cm insulated panels can create temporary insulated structures. For instance, at agricultural fairs or events, temporary insulated stalls or kiosks for dairy or meat products can be constructed that maintain product integrity for on-site demonstrations or discussions.

When choosing the ideal 5 cm sandwich panels, it is important to consider several factors to ensure the selected panel meets the intended application requirements. Some of the factors to consider are:

Purpose

Clearly define the purpose for which the panel is to be used. In this case, determine whether it will be used for roofing, walls, cold rooms, or any other specific use.

Insulation requirements

Different materials have different R-values. The R-value is an indicator of a material's ability to resist heat flow. Therefore, opt for a material with an R-value suitable for the intended climate and location. For example, if the panel is intended for a location with extreme temperatures, consider choosing a panel with a high insulation value. The R-value of 5cm sandwich panel varies with the core material. For PUR/PIR foam, it is 25.5-27.5; for EPS foam, it is 18-20; and for Rockwool, it is 14-16.

Structural integrity

Assess the structural requirements of the intended installation site. Consider the load-bearing capacity of the panel. Additionally, opt for a core material that can provide the necessary strength. For instance, choose a structural grade steel for high-strength requirements. Typically, the panel's design strength depends on the core material. The core material provides structural integrity, with PIR foam panels having the highest strength, followed by EPS and Rockwool.

Moisture control

Consider the sandwich panel's ability to resist moisture. In this case, panels with a core material that can provide adequate vapor barriers and insulation should be prioritized. Such core materials include EPS and PIR foams.

Fire safety

It is important to check the fire rating of the sandwich panel. This is to ensure it meets the local building code requirements. In this case, opt for panels with fire-resistant core materials for enhanced safety. These include PIR and Rockwool.

Aesthetic considerations

When applicable, it is important to consider the aesthetic qualities of the selected 5 cm sandwich panel. This includes finishes, colors, and textures. These factors should complement the overall design of the intended project.

Q1: What is a sandwich panel 5 cm?

A1: A 5 cm thick sandwich panel is a composite building material consisting two steel sheets and a 5 cm thick foam core (usually polyurethane foam or polystyrene foam). It's called a sandwich panel because the foam core is like the filling in the sandwich, and the steel sheets are the bread.

Q2: What is the purpose of a 5 cm thick sandwich panel?

A2: The main purpose is to provide walls or roofs for buildings. The foam core gives insulation to keep buildings warm or cool. The steel sheets make the panel strong so it won't bend or break easily.

Q3: What are the advantages of using a 5 cm thick sandwich panel?

A3: Some advantages include:

Q4: Where are 5 cm thick sandwich panels used?

A4: They're used for many types of buildings like warehouses, garages, coolers, offices, and houses. The panels can make walls or roofs for these structures.

Q5: How long do sandwich panels last?

A5: With proper care, a 5 cm thick sandwich panel can last 30 years or more. The steel sheets are very durable and resist damage. As long as the panels stay dry and aren't exposed to sharp objects, they have a long lifespan.