All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(46782 products available)

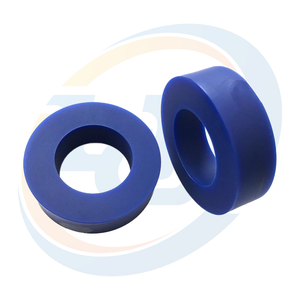

A rubber bushing is a flexible rubber component fitted between two metal components. It is used to reduce the transmission of noise, vibration, and harshness (NVH) from one part to another. Bushings are fitted in various parts of a vehicle, including the suspension system, transmission, and steering system. The main function of bushings is to minimize the wear and tear of components in mechanical systems. The bushing is subjected to wear and tear in place of the parts it protects. Bushings come in different materials, including polyurethane and nylon. Here are some of the most common types of rubber bushings:

Hollow Rubber Bushing

The hollow rubber bushing has a hollow core. It is mostly used in hydraulic fittings, electrical conduits, and plumbing applications. The hollow core of the bushing helps to absorb vibrations and noises in a system. It makes the bushing last longer.

Solid Rubber Bushing

On the other hand, a solid rubber bushing is fully filled with rubber. It is commonly used in suspension systems, especially for heavy-duty vehicles. Solid bushings are used in places where noise and vibrations cannot be tolerated.

Metallic Rubber Bushing

A metallic rubber bushing combines rubber and metal components. The metallic components are usually made from aluminum or steel. The metallic bushing is used in applications that require electrical conductivity.

Flanged Rubber Bushing

The flanged bushing has a flange at one end. The flange acts as a stopper when fitting the bushing in a component. The flanged rubber bushing is used to connect pipes and fittings in various plumbing applications.

Threaded Rubber Bushing

The threaded rubber bushing is fitted into threaded fittings. It is used to reduce the flow of water in plumbing applications. A threaded bushing is used when one needs to close off a pipe.

Rubber bushings come in diverse specifications that suit a wide range of applications. Here are some of the key specifications to consider when buying rubber bushings:

Bushing Size

The size of a rubber bushing refers to the inner and outer diameter and the width or length of the bushing. The bushings are available in different sizes to fit various sizes of rods and pipes.

Type

There are several types of rubber bushings, each designed for a specific purpose. For instance, the spherical bushing is commonly used in suspension systems, while the cylindrical bushing is used in various applications involving rotational movement.

Material

Different grades and formulations of rubber are used to manufacture rubber bushings. Each type has its unique features that make it suitable for a specific application. For instance, bushings made from natural rubber have excellent tensile strength and high resistance to abrasion, making them ideal for use in automotive parts.

Hardness

The hardness of a bushing affects its performance and suitability for specific applications. Bushings with a higher hardness level offer a higher load capacity and resistance to wear. On the other hand, bushings with a lower hardness level provide noise and vibration dampening.

Load Rating

Load rating refers to the maximum load that a rubber bushing can support without failure. Buyers should select bushings with a load rating that matches their application requirements.

Fitment

Rubber bushings are designed to suit various types of vehicles and machinery. For instance, some bushings are made to fit specific models of cars, while others are designed to fit heavy-duty trucks and construction machinery.

Rubber bushings are vital components in machinery and vehicles. However, like any other component, they wear out over time. Here are some of the signs that a rubber bushing has failed.

Maintaining rubber bushings helps to prolong their lifespan and ensure they perform efficiently. Here are some maintenance tips:

Choosing the right rubber bushing can be a daunting task considering the variety of options on the market. Here are some key factors to consider when choosing rubber bushing:

Application

When considering the application, it means the specific area or part of the vehicle system where the bushings will be installed. This is important because different applications have different requirements and conditions. For example, the suspension system bushings absorb shocks and impacts from the road. Thus, they require bushings that are more durable and can withstand harsh conditions. On the other hand, the transmission bushings are mounted on a smooth and less demanding mounting environment. Transmission bushings can be mounted and made from softer materials than suspension bushings.

Material

Rubber bushings are available in a variety of materials, each suited for different applications. Choosing the right material for the application is important due to the different advantages and disadvantages each material has. Choosing the right material for the application ensures optimal performance and durability. Here are some of the most common materials and their advantages: Natural rubber: These are bushings that offer a quiet and smooth operation. They are suitable for applications where noise and vibration are a concern. They are mostly used in the engine and transmission mounts. Nitrile rubber: This is a versatile material that is resistant to oil, fuel, and other chemicals. It is suitable for applications where exposure to these substances is possible. It is mostly used in the chassis and suspension bushings. Polyurethane: These are bushings that have a higher durability and wear resistance compared to natural rubber. They are suitable for heavy-duty applications or when increased load-bearing capacity is required.

Size and specifications

This involves choosing a bushing that is compatible with the mounting points of the components being connected. When considering size, it is important to pay attention to the diameter, length, and width of the bushing. Choosing the right size and specification is important because it ensures proper fitment, functionality, and performance of the bushings.

Hardness

Hardness is an important factor when choosing rubber bushings due to its effect on performance and characteristics of the bushing. Bushings are available in different hardness levels, usually measured on the Shore durometer scale. Hardness affects the bushing's resistance to compression, vibration absorption, and overall performance. Choosing the right hardness level is important because it influences the bushing's ability to perform its intended function. The hardness requirement is mostly determined by the application and specific requirements.

It might be a challenging DIY project to replace a rubber suspension bushing, but it is doable with the right tools and skills. Here is a step-by-step guide on how to replace rubber bushings:

Tools Needed:

Steps:

Q: What is a rubber bushing used for?

A: Rubber bushings are used to reduce noise, provide flexibility, and allow misalignment in various applications.

Q: What is the difference between rubber and polyurethane bushings?

A: Rubber bushings are primarily used for general-purpose applications, while polyurethane bushings are suitable for high-performance and heavy-duty applications.

Q: How long do rubber bushings last?

A: Rubber bushings can last between 30,000 to 100,000 miles, depending on various factors such as the type of vehicle, driving conditions, and the quality of the bushing.