All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(7054 products available)

A router bit set is used in different ways to carry out different tasks. However, the set that goes for the user's job is determined. The following section outlines some of the most common types in the marketplace today.

A core bit is used to extract the thickest part of a substance contained in a cylindrical core sample. This core bit is in most cases applied as a diamond core bit, which is suitable for hard materials such as concrete and masonry with a diamond-cut edge of the hollow cylinder-framed core bit.

At the same time, non-diamond types which are usually steel-based, apply to softer materials like wood. Common widths in a woodworking core bit include:

Countersink bits are used to make a conical shaped sink holes in a workpiece for countersunk fasteners such as screws or bolts. This avoids fasteners sticking out of the surface but allows them to sit even with or flush to finished surface. Typical features of countersink bits:

They fashion a range of angled edge profiles on cabinet doors, shelves, and other woodworking projects, such as cutting, chamfering, or beveling, among some. Key attributes include:

Groove cutting bits or straight router bits cut straight, smooth grooves into flat workpieces. Groove-setting bits use a vertical bit shape, which is ideal for creating dado grooves, slots, or channels. Typical characteristics include:

Router bits set usually has a fully hardened steel composition, which ensures durability by increasing the service life of the tool. It does this by reducing wear and tear on the cutting edges. Well-made steel-based bits withstand frequent use without losing their structural integrity or snapping, making them suitable for professional contractors or carpenters who use their tools daily. The rugged material means less chance of replacement, saving money in the long run.

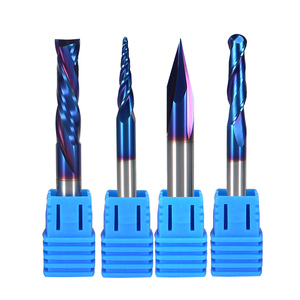

The Tungsten carbide tips are incorporated into the router bits, which stand for the sharpest edge and a longer life. The tips allow them to cut, carve, or shape evenly. Furthermore, Tungsten carbide is hard enough to withstand abrasion; thus, these bits do not wear down under heavy use from cutting woods, plastics, or other materials. They keep shaping the texture required for those hard-to-shine areas and ensure precision for every cut, thus eliminating sloppiness.

The durable storage case keeps router bits organized and protected. The storage box is usually made of hard plastic or metal to withstand wear and tear. It keeps bits from getting lost or damaged between uses. Each groove or slot inside the box is specifically designed to hold individual bits so they don’t jumble around. This handy feature lets people quickly find what they need for projects without delay.

A router bit sharpener uses sharpened steel to grind and hone tungsten carbide router bits to provide a sharp edge. This helps the user work more effectively by returning old bits back to a useful condition and saving money since new bits are expensive. It is done using special guides to keep the bit stable and exactly angled against the abrasive wheel, sanding the worn metal away evenly from both sides and the edge until it is just like a new bit hangs in the groove of the sharpener guide.

The bits toolkit comes with special tools for applying to different home repairs ranging from cutting, carving, edging, and shaping, among others. The following sections examine some common router bit set applications.

The cutting tools allow users to edge wood on tables and other furniture to give a classy rounded or beaded look. Specifically, rounding over bits ease up any sharp corners so they are not eye-poking angle areas. It makes the edge softer. Bead mold cutters cut smooth, round little dimples into the edge to create a nice bumpy decorative trim.

Using these bits is simple – just clamp the wood securely and run the router with the bit set along the edge to be styled. This transforms ordinary square edges into attractive, eye-catching designs to dress up any shelving, tabletops, or other wood surfaces.

Some bits in the carpentry tools kit fashion grooves and slots in plywood, particle board, and other built work items and fixtures like shelves and cabinets. Straight bits cut smooth, deep grooves into the sheet materials.

Which groove width is cut depends on the project: routine jobs like installing standard shelves use normal-width bits, while more complex tasks needing joints or special fasteners require wider ones. This means home crafters can single-handedly cut the precise grooves needed for various stock cabinet and shelving systems without an expensive custom router.

A plunge router is controlled to set precise groove depth stops and run straight along the guide edge of a fence to smoothly cut the groove.

Special profile and molding bits carve out eye-pleasing decorative edging along wood trim for baseboards, crown molding, window, and door frames. These bits create various detailed surface shapes, such as fluting, beading, or chamfering, to stylishly dress up plain trim.

It makes adding custom architect-style features to interior finishing very easy. Just attach the desired profile bit to the router, run it along the wood edges, and it scores gorgeous detailed designs quickly and professionally. This lets homeowners and builders richly enhance construction appearances without hiring expensive pro services.

Flush trim and dado bits cut perfectly level recessed areas on wood surfaces to inlay other materials like laminate, plywood panels, or solid wood pieces. For example, laminate countertop surfaces require the substrate plywood cut to precisely accept any sinks or stove inserts. The router dado blade makes this recess-cutting routine fast and accurate.

It allows the homeowner to route the necessary recess essentially leveled with the leading countertop surface for any desired inlay. This significantly opens up handy do-it-yourself modifications options for cabinet topping, vanities, and other assemblies without needing a professional.

Some bits, such as rail and stile cutters, are specially shaped to carve out interior-style molding. The cutters work much like a molding machine, running along the edges of the wood pieces to indent them precisely as needed.

This allows creating a classy jointed frame molding profile for cabinet doors, window, and mirror framing. It gives the distinct multi-piece interior molding style without all the complicated assembly work. Just shape the wood and clamp them together for a neat, professional-looking interior.

The home router kit can last several years with a little prep and consideration from the user. The following sections outline the general maintenance routine that is fundamental to sustaining the device's reliability and performance.

Once every bit set is used, it is critical to eliminate all sawdust, dirt, and resin buildup. This is because debris lodged in the cutting edges causes corrosion to set in and dull the edges. Therefore, when cleaning it, it is advisable to use a soft-bristled brush to wipe off all the residue. A special router bit cleaner or rubbing alcohol can remove sticky pitch deposits from bits.

A well-organized hard case maintains consistent sharpness of the bits by preventing damage through jostling or cross-contamination and the storage of bits umbrellaed by their proper groove. The form-fitted storage case is strong enough to bear usage over time without breaking or wearing out. An efficient user will ensure that the bits are fully dry before storage to eliminate rusting in humid environments.

Losing its sharpness is a natural transition of router bits over time with usage. This translates into less effective and precise cuts. A prominent sign of dull bits is excessive pressure during operation. Sharpening the bits using a dedicated sharpener returns the edges back to the original factory standards. Frequent professional sharpening services translate into a longer life cycle for the router bits and reduce the costs of acquiring new sets.

For users who intend to travel with the router bits set, it would be prudent to invest in a quality padded bag or bit cases to protect the bits from impact and ensure that they are not kicked about. A padded bag would cushion them in the event of bumping or collision, while the padded case would provide a sturdy home for each individual slot so that none were lost or tangled together. Protecting these tools when transporting them preserves their cutting precision and prolongs their useful life.

A close examination of every bit before each process or after storage practices helps to note the presence of any small problems like cracks or missing teeth. Catching such wear and tear issues early on means they can either be fixed, and reliable work isn't compromised. After all, safety is only possible with tools in optimum shape.

A1: Common bit diameters include 1/4 inch and 1/2 inch for various routing needs. These fit most router models as they have collet sizes that accommodate popular bit shanks to offer customization. A user should check specific router requirements for ideal integration.

A2: Straight and dados router bits are better suited for g routing wood veneered sheet materials since they exhibit a flat bottom and straight side. This enables the groove cut to be smooth and level, which offers ideal support for joint assembly in cabinetry work.

A3: The notable signs are:

A4: Yes, various bits exist for specific materials - some ideal for cutting hardwoods, softwoods for others - plastics, composites - metals. Each bit shapes the cutting edge and material to optimize performance and avoid damage or dulling.

A5: Router bases are not universal. Each router model has a distinct baseplate size and shape due to incompatibility. However, there are bases manufactured to accommodate multiple routers if they require the same model, hence creating interchangeability.