Understanding Rotation Counters: Introduction

A rotation counter is an essential device for measuring and monitoring the number of rotations or revolutions carried out by a particular mechanism or machine. Typically used in industrial applications, rotation counters are crucial for maintaining efficient operations, ensuring safety, and preventing wear and tear on machinery. With versatile applications across various sectors—like manufacturing, automotive, and aerospace—these devices enable businesses to improve accuracy in performance metrics while enhancing productivity.

Types of Rotation Counters

When it comes to rotation counters, different types are designed to suit various applications and operational environments. Understanding the types available is vital for selecting the right unit for your specific needs. Here are some common types:

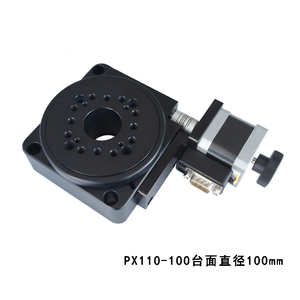

- Mechanical Rotation Counters: Simple yet effective, these counters utilize mechanical gears and dials to display and record the number of rotations.

- Digital Rotation Counters: Offering increased accuracy and ease of use, digital counters display numbers on an electronic screen, making it easier to read and analyze data.

- Programmable Rotation Counters: These advanced units allow users to set up specific parameters, such as limits for alerts and historical data logging for comprehensive analysis.

- Wireless Rotation Counters: Utilizing RF technology, these counters send data to a central database, enabling real-time monitoring of performance across multiple machines.

Applications of Rotation Counters

Rotation counters find their utility in various industries and applications, demonstrating their versatility and importance in operational efficiency. Key applications include:

- Manufacturing: Used to track the number of cycles for machinery to ensure regulative maintenance and operational reliability.

- Automotive: Essential for vehicle testing and research, helping engineers monitor performance metrics during prototypes and tests.

- Aerospace: Critical in flight testing to document and analyze rotational dynamics of aircraft components.

- Research and Development: Supporting experiments where precise measurement of rotations is crucial for data collection and analysis.

Features and Advantages of Rotation Counters

Modern rotation counters come equipped with a variety of features and advantages to serve their users effectively. These benefits make them indispensable tools in numerous contexts:

- Accuracy: Advanced sensors and technologies ensure high precision in the measurement of rotational metrics.

- Durability: Built to withstand industrial environments, many rotation counters are resistant to moisture, dust, and mechanical wear.

- Ease of Use: User-friendly interfaces allow for straightforward data reading and maintenance, making them accessible for operators of all skill levels.

- Data Logging: Many models come with data logging capabilities, allowing users to track performance over time and make informed decisions based on historical data.

- Customizable Alerts: Programmable units can be set to alert users when thresholds are reached, enhancing proactive maintenance and operational awareness.