Introduction to Rotating Casing Scrapers

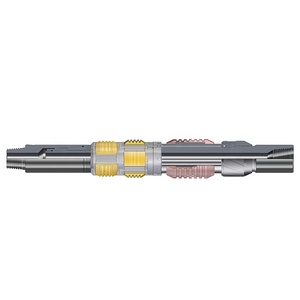

The rotating casing scraper is a crucial tool in the oil and gas industry, primarily used during drilling operations to clean the wellbore and enhance the efficiency of downhole operations. Its primary function is to remove cement, mud, and debris from the casing walls, ensuring a clear path for tools and improving overall well integrity.

Designed to optimize performance, rotating casing scrapers are engineered to work effectively under the challenging conditions of high-pressure wells. By utilizing a rotating action combined with cutting edges, these scrapers can efficiently tackle tough residue, making them indispensable for any drilling rig.

Types of Rotating Casing Scrapers

Rotating casing scrapers come in various types to cater to different well conditions and operational requirements:

- Mechanical Rotating Scrapers:

- Utilizes mechanical components to rotate and scrape the casing.

- Ideal for softer formations with minimal debris.

- Pneumatic Rotating Scrapers:

- Operates using compressed air for rotation.

- Suitable for challenging environments and deeper wells.

- Hydraulic Rotating Scrapers:

- Employs hydraulic power for enhanced torque and scraping efficiency.

- Best for heavy-duty use in wells with significant buildup.

- Fixed Blade Scrapers:

- Features fixed blades designed for lighter scraping tasks.

- Effective for preliminary cleaning before utilizing mechanical scrapers.

Function and Features of Rotating Casing Scrapers

Rotating casing scrapers employ unique features and functions designed to ensure thorough cleaning and maintenance of the casing. Key aspects include:

- Rotational Movement:

- Allows for even scraping around the casing’s circumference.

- Enhances effectiveness against stubborn deposits.

- Interchangeable Blades:

- Available in various materials such as carbide for durability.

- Facilitates easy maintenance and replacement based on well conditions.

- Pressure-Tolerant Design:

- Constructed to withstand high-pressure scenarios without failure.

- Ensures reliability during critical drilling operations.

- Universal Compatibility:

- Can be adapted to fit various casing sizes and types.

- Streamlines operations, minimizing the need for multiple tools.

Applications of Rotating Casing Scrapers

Rotating casing scrapers find applications across diverse sectors, primarily in drilling and well-maintenance tasks:

- Oil and Gas Exploration:

- Essential for preparing well casings before logging and completion.

- Improves accuracy during subsequent drilling phases.

- Maintenance and Repair:

- Frequently used in workovers to clean out old equipment and debris.

- Helps restore wellbore integrity for continued production.

- Well Abandonment:

- Aids in cleaning the casing before sealing procedures.

- Ensures comprehensive sealing, minimizing environmental impact.

- Deep-Well Applications:

- Adaptable for use in ultra-deep wells with specialized designs.

- Improves operational efficiency and reduces downtime.