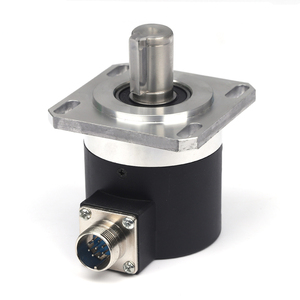

Understanding Rotary Encoder Circuit

A rotary encoder circuit is a crucial component in various electronic systems, providing precise position feedback from rotating devices. By converting the angular position or motion of a shaft into an electrical signal, rotary encoders enable advancements in automation and control systems across diverse industries. These circuits are integral to robotics, motor control, and precision instrumentation, offering unparalleled accuracy and reliability.

Types of Rotary Encoder Circuits

- Incremental Rotary Encoders: These encoders provide a series of digital pulses as the shaft rotates, allowing the measurement of speed and direction. They are widely used in motion control applications due to their simplicity and efficiency.

- Absolute Rotary Encoders: These encoders provide a unique position value for every angle of rotation, ensuring that the absolute position is known without the need for reference or recalibration. They are ideal for applications requiring high precision and reliability.

- Magnetic Rotary Encoders: Utilizing magnetic fields to determine the position, these encoders are resistant to environmental conditions such as dust and moisture. They are often used in outdoor or rugged environments.

- Optical Rotary Encoders: These encoders use light to detect position changes, providing high resolution and accuracy. Common in applications that demand detailed feedback, they are typically utilized in robotics and automation settings.

Applications of Rotary Encoder Circuits

- Robotics: Rotary encoder circuits are essential for detecting joint angles and enabling precise movement in robotic arms, making them an indispensable part of robotic design.

- Industrial Automation: Used in conveyor systems and assembly lines, rotary encoders help control the speed and positioning of machinery and products, enhancing overall efficiency.

- Consumer Electronics: Many devices, such as volume controls and tuning knobs, rely on rotary encoders for user-friendly interaction, translating user input into digital commands.

- Medical Equipment: Accurate position feedback is critical in medical devices such as MRI machines and robotic-assisted surgery systems, where rotary encoders play a vital role in ensuring precise movements.

Features and Benefits of Rotary Encoder Circuits

- High Accuracy: Rotary encoders offer exceptional precision in measuring angular position, making them suitable for applications that require fine control.

- Low Maintenance: These circuits are designed for durability and longevity, often requiring minimal maintenance over their operational life, which reduces downtime and costs.

- Versatility: Available in multiple formats and variations, rotary encoders can be adapted for various industrial needs, making them highly versatile components in electronic design.

- Software Compatibility: Rotary encoder circuits are compatible with various programming languages and control systems, facilitating easy integration into existing infrastructures.

- Real-time Feedback: By providing instant position data, these encoders enable real-time control and adjustments, enhancing the overall responsiveness of the system.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4