(10747 products available)

Rice separator machines are an important part of the food processing and agricultural industries. These machines are used to sort and clean rice by separating impurities like husks, dust, and sand. They also separate broken grains from whole ones. There are two main types of rice separators: paddy rice separator and brown rice separator.

The paddy separator machine processes paddy rice (unhusked rice). Its primary function is to remove impurities and clean the paddy before dehusking. It separates foreign particles like dirt, dust, and straw from the paddy. The clean paddy is then ready to be dehusked either manually or with the help of other rice processing machines.

After dehusking the paddy rice, the brown rice separator takes over. It is further used to remove any remaining impurities like bran, husk, and other particles from brown rice grains. After the cleaning process, the machine produces clean and whole rice grains ready for consumption or further processing.

The functionality and longevity of a rice separator machine depend on proper maintenance. Knowing the machine's specifications allows for more efficient and effective maintenance.

Rice separator machines are categorized based on capacity. Small-capacity machines can process between 500 and 1000 kilograms of rice per hour. Medium-capacity machines can process between 2,000 and 3,000 kilograms of rice per hour. Large-capacity machines can process between 3,000 and 5,000 kilograms of rice per hour.

The motor power rating determines the machine's ability to separate rice and its power consumption. Small-capacity machines have motors with 1.5 to 3 kW of power. Medium-capacity machines have motors with 3 to 5.5 kW of power. Large-capacity machines have motors with 5.5 to 11 kW of power.

The dimensions and weight of rice separator machines vary depending on the capacity. For example, the height, width, and length of a small-capacity machine may be around 1000 mm, 500 mm, and 1200 mm. A medium-capacity machine may be around 1200 mm, 800 mm, and 1500 mm. A large-capacity machine may be around 1500 mm, 1000 mm, and 1800 mm.

Small-capacity machines have weights of about 150 kg. Medium-capacity machines have weights of about 320 kg. Large-capacity machines have weights of about 600 kg.

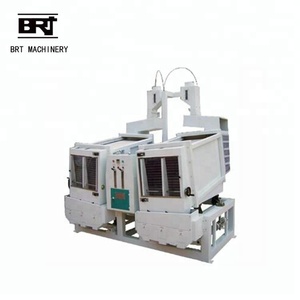

A rice separator machine has many parts and components. They include the hopper, the feeding system, the sieves, the drive system, the fan, the outlet, the support frame, and the electrical control system. The hopper is the container that holds rice. The feeding system moves rice through the machine. The sieves separate rice based on size and weight. The drive system operates the sieves. The fan creates airflow. The outlet discharges rice. The support frame holds the machine. The electrical control system manages the machine's functions.

Following a maintenance schedule is important to keep a rice separator machine in good working condition. Daily maintenance includes cleaning the machine before and after use. This prevents residue from building up. Weekly maintenance includes lubricating moving parts. This prevents premature wear and tear. Monthly maintenance includes inspecting the machine's electrical components. This ensures everything is connected and working as it should be. Regularly scheduled maintenance includes checking the machine's belt drive system.

With the advancement of food technology and machinery, rice separator machines are receiving increasing attention in various fields.

In the food processing industry, especially in the production line of rice and flour, the rice separator machine plays an essential role in removing impurities from the raw material. In addition to separating rice, the machine can also sort other cereals, nuts, beans, etc., which greatly improves the efficiency of the entire production process.

In agriculture, the rice separator machine is used to separate and classify rice after harvesting. It is not only suitable for rice but also for sorting other grains. Rice separator machines can improve the quality of specific agricultural products and increase their added value by separating them according to size, weight, color, and other characteristics.

Service industry

In the service industry, such as catering, hotels, and restaurants, using a rice separator can help improve the quality of dishes, making the rice and ingredients used in cooking more refined and pure. It helps to ensure food safety and enhance the dining experience for customers.

In the field of research and development, the rice separator machine can be used in laboratories and research institutions to conduct experiments and studies on grain separation and classification. It can help researchers and scholars understand the characteristics of various grains better and improve their knowledge of cereal science.

Medical use

In the medical field, the rice separator machine can be used for various types of drugs, reagents, and other materials that need to be accurately weighed and separated. It ensures the accuracy and consistency of dosage, which is essential for drug research and development and production.

With the continuous development of technology, the application fields of rice separator machines will continue to expand, and new use scenarios will continue to emerge.

Choosing the right rice separator machine for business use requires careful consideration of several key factors.

Consider the volume of rice that needs to be processed. Match this with the machine's rated capacity, typically expressed in kilograms per hour. Select a machine that can handle the business's typical processing demands to ensure efficient workflow.

Determine the specific functions required, such as cleaning, de-stoning, husking, or polishing. Select a machine that offers the necessary processing steps for the desired rice product. Also, consider the flexibility of the machine to accommodate different types of rice varieties.

Decide the preferred automation level based on the operator's skill level and business efficiency. Fully automated machines offer hands-free operation but may require greater upfront investment. Semi-automated or manual machines are more cost-effective but demand more human involvement.

Depending on the business's quality requirements, assess the precision of the separation performed by the machine. Choose a machine that can consistently deliver the desired level of purity and quality in the final rice product.

Determine the machine's power needs and ensure compatibility with the business's infrastructure. Consider energy efficiency to minimize operating costs. Select a machine that balances power efficiency with performance.

Choose a machine made of high-quality materials and built to withstand the demands of commercial use. Investing in a durable machine will minimize maintenance and replacement costs over time.

Evaluate the initial investment cost and consider the long-term cost of ownership. While budget plays a role, prioritize overall value and performance. Consider maintenance requirements, potential repair costs, and energy efficiency to ensure the machine's long-term affordability.

Q1: What is the capacity of a rice separator machine?

A1: Rice separator machines come in various capacities, and determining the right one ensures the machine works efficiently. The capacities vary from a few hundred kilograms to several tons per hour.

Q2: What is the difference between a rice separator machine and a grain separator machine?

A2: The main difference is the size of the two machines. A rice separator machine is much smaller than a grain separator machine. Rice separator machines are designed for use in rice mills and are used to separate impurities from rice. Grain separator machines, on the other hand, are designed for use in farms and are used to separate impurities from grains before storage.

Q3: Can a rice separator machine separate different rice varieties?

A3: Yes, a rice separator machine can separate different types of rice. This is because rice separator machines are designed to separate rice based on their size and density. As a result, a machine can separate different rice varieties or grades.