All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(1137 products available)

Multiple kinds of resolvers are there in the market that people employ for various applications. It will be meaningful to gain knowledge about the diverse forms and their pros and cons, enabling people to decide which resolvers will suit them the most. Below are the most common types of resolvers and digital converters.

Oil-filled resolvers are the specific type of electric motor components designed for durability and use in harsh environments. These are the spaces where high temperatures and pressures will be encountered. They are fabricated by enclosing the resolving element in an oil-filled housing to help protect it from the environment and serve as a coolant to the element. They are vital to industries like mining, petroleum, and gas, as they are known to offer stubbornness while keeping the good functionality.

Electrical and magnetic resolvers are used to acquire position information. While electrical resolvers utilize voltage and resistance to know of an object's position, magnetic resolvers use a magnetic field. These will be applied in various contexts, including robotics and automation, where accurate positioning is very important. They hold potential for high accuracy and reliability in their functioning.

Digital angular resolvers are high-tech devices designed to transmit the measured angular information in a digital format. These devices will likely replace the analogue technologies since they offer more precise readings. Digital angular resolvers are widely employed in the aviation sector, mainly because they can provide accurate and dependable location readings even at high performance. These types of instruments are also applicable in guidance systems of spacecraft, which entails a need for optimal precision.

Capacitive resolvers are a special kind of angular position transducer that works by measuring the change in capacitance to find the angular displacement. These devices are prized for being highly sensitive, meaning they will measure slight changes in angles. Because of this feature, they become widely used in the fields of microelectronics and nanotechnology, where accuracy is everything. Capacitive resolvers offer contactless operation, making them suitable for environments where wear and tear on mechanical components happens easily.

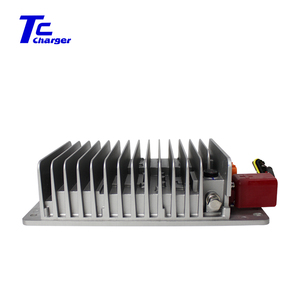

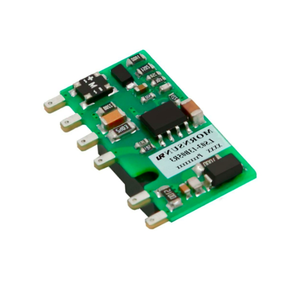

Contemporary industrial operations involve various technologies and components to ensure optimum efficiency, reliability, and performance. One such component is the resolver-to-digital converter (RDC board), which translates the resolved analogue signals into digital formats for precise position and speed measurements with high accuracy in motor control, robotics, and aerospace systems. Some of the industrial applications include:

These boards are critical to any electric motor and servo system's operational efficiency and accuracy. They are mostly applied on electric motors that demand a high resolution and dynamic control, such as premium industrial servos employing high-speed motors. At such points, the RDC can help translate the analogue signals from the resolver into a digital format understood by modern control systems to ensure proper motor working. Also, they are employed in robotics for precise control of robotic arms, manipulators, and joints to provide the needed accuracy in the RPs and torques.

These boards help position and speed feedback in various applications. Any system, including satellites, military aircraft, or missile guidance systems, requires high precision, reliability, and the ability to work under difficult conditions. RD boards are ideal in such situations, providing accurate feedback even in extreme temperatures and other conditions. By feeding back accurate position and speed information to control systems, RD boards enable more precise navigation, stability control, and guidance. Moreover, their capacity to function in real-time plays a vital role in dynamic environments where immediate feedback is necessary.

As the IoT and Industry connect more and more, the demand for resolving feedback mechanisms within these frameworks is increasing. The RDC boards give an advantage in providing accurate position data for monitoring motor health and other vital parameters in real-time. In industrial systems, these boards can help detect anomalies in motor functioning by continuously relaying accurate position data, which can be used to set predictive maintenance alarms. Such predictive maintenance systems will reduce downtime, lower repair costs, and increase operational efficiency.

In robotics, performance, precision, and control are crucial as their primary focus is about harnessing these elements. The resolvers are applied to provide accurate position information for robotic arms, manipulators, and joints to control the machine as precisely as human limbs. Hence, the RDC boards convert these position signals into digital formats to facilitate effective control of these motors. This whole process will yield smoother operations, improved accuracy for tasks, and better feedback mechanisms.

The resolver digital converter boards have a number of important features that contribute to their effectiveness in industrial applications. Some of them include the following:

High accuracy

RDC boards are meant to offer premium levels of resolution and precision by converting analogue signals from a resolver into digital output. This ensures accurate control and feedback in high-tech applications like robotics, aerospace, and electric motors.

Real-time processing

These boards allow real-time data processing and feedback in dynamic situations, enabling systems to adjust promptly and maintain performance within the required operational limits.

Wide operational range

These boards can work with many resolver types and can operate under various environmental conditions, making them adaptable to multiple industrial needs. Temperature, speed, and other parameters won't affect their performance, making them suitable for various industrial applications.

The installation of an RDC board will require some steps to be aligned to realize proper functioning capabilities, as seen below:

Mounting of the board

The mounting of the board being done in a proper housing or enclosure is important to prevent dust and other external elements from damaging it. The board, too, must be mounted in a way that its connectors and other related components are easily accessed while ensuring it is stable and does not vibrate or move around during its usage.

Electrical connections

The electrical connections then have to be made between the RDC board and other system components. This involves wiring the power supply to the board and connecting the input from the resolver and the output to the data processing unit or controller. At this stage, pay close attention to the wires to ensure correct voltage and signal type for smooth operation.

Calibration

The calibration of the RDC board is then necessary to ensure accurate signal conversion. The calibration process involves setting the board to understand the specific characteristics and parameters of the resolver it is working with. Depending the boards calibration requirements, this might involve software settings adjustments or running calibration procedures that put the board through its paces to record how it performs with expected input signals.

Testing

After finishing the above steps, testing the installation will check whether everything has been set and working well. This involves applying a known input to the resolver and checking whether the board provides the expected output. Any discrepancies noticed would potentially mean revisiting calibration or making connections to ensure correctness.

To ensure the RDC boards are maintained effectively, the owners need to follow the steps below. This way, they can provide the required maintenance and repairs and ensure smooth operations in the industry.

Preventative maintenance

The preventive maintenance occurs because it will be all about the dust and debris that will accumulate over time. This dirt accumulation leads to overheating and, thus, the breakdown of the RDC boards, hence the need for some cleaning to be done. The cleaning should be frequent, done weekly or after some days, depending on the amount of dirt in an area. Cleaning should be done with a soft brush or compressed air to eliminate all the dust without causing an electrical short circuit or damage to the board. The temperature conditions should also be well monitored.

Regular updates

The firmware and software used in the RDC board should be updated on time to fix bugs and improve system performance. These updates would be checked for by going to the manufacturer's website or the software platform where users upload the product drivers and other related software. The updates are to be followed as per the manufacturer or developer instructions to ensure the board operates at optimal effectiveness.

Frequent diagnostic testing

The diagnostic testing should be frequent as it checks the performance of the RDC board, looking for any small problems before they get any bigger. Run the diagnostic software or use the testing tools developed by the manufacturer to analyze the board's functioning and potentially signal wear and tear.

Wear parts replacement

If there are any worn-out parts, such as cooling fans or power supply capacitors, easily replace them with original spares so as not to compromise the board's performance.

Any system's quality and safety implications are crucial for the RDC boards concerning performance, reliability, and the ability to work properly in hazardous working conditions. Thus, some key quality and safety features of these boards are described below:

High precision

The accuracy level brought in this conversion process is high due to these high-resolution RD boards, which give accurate position and speed signals. It is important not to compromise this on any board used in heavy industries like robotics, electric motors, and space systems.

Reliability

The reliability count of these boards, especially in industrial setups, is high, meaning the accuracy and performance will not degrade over time or under tough working conditions. The board's ability to provide consistent output irrespective of the environment enhances this operational efficiency and decreases downtimes.

Real-time processing:

The capability of these boards to process and convert the resolver signals in real time means there will always be responsive and up-to-date feedback even in dynamic industrial operations. This feature enables systems to operate safely as the reactive controls help avoid potential hazards or performance issues in the system.

Thermal management:

The critical element that cannot be compromised is thermal management on an RD board. Any excessive heat will damage the internal components and affect performance. To this end, proper cooling systems and board housing will maintain temperature within tolerable limits, ensuring safe operations.

Signal integrity:

Signal integrity also is a very important safety issue. Any noise or interference on the signals from the resolver can lead to wrong conversion and output, potentially causing unsafe conditions in the system. Shielding, filtering, and proper grounding will help maintain signal integrity and prevent any safety problems that may arise.

Power supply stability

A stable power supply is critical for the safe functioning of these boards. Any fluctuation or instability in power can lead to malfunction or erroneous output, which might be hazardous in critical industrial setups. Use power supply conditioning and UPS to ensure stable power delivery to the board.

A1. The RDC boards convert the resolver's analogue signals to digital outputs, determining the exact position and speed of the apparatus and giving an accurate feedback mechanism mainly found in electric motors, aerospace, and robotic applications.

A2. Yes, These Boards can be housed in weatherproof or rugged enclosures resistant to dust, moisture, and temperature extremes, making them suitable for outdoor use in various industrial and environmental conditions.

A3. "Cleaning the board frequently, providing good thermal management, and carrying out regular firmware updates are some ways to prevent and extend the lifespan of an RDC board.")

A4. An RD board should be replaced when wear leads to decreased accuracy, an inability to process in real-time, or board signal loss reoccurs.

A5. Manufacturing, Aerospace, Robotics, and Telecommunications industries are typical applications that employ these boards due to their need for precise control and positioning.