All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(6765 products available)

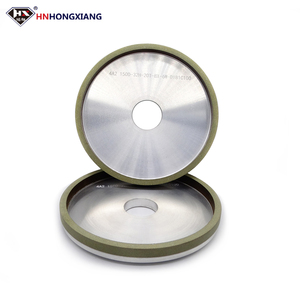

Resin bonded diamond wheels are advanced grinding tools widely celebrated for their exceptional performance and versatility in various industries. These wheels integrate diamond abrasives with a resin-based bonding material, which not only ensures higher durability but also improves the efficiency of grinding operations. The unique properties of resin bonded diamond wheels make them indispensable for precision machining, surface finishing, and even intricate detailing tasks across different materials.

Understanding the different types of resin bonded diamond wheels can help you select the right one for your specific applications. Here are some common types:

The versatility of resin bonded diamond wheels allows them to be used in numerous applications across different industries:

Resin bonded diamond wheels come with a range of features that make them standout solutions in the grinding world. These include:

In summary, resin bonded diamond wheels are an essential asset in a variety of industrial applications. Their unique combination of durability, efficiency, and exceptional performance is what makes them highly valued in today’s manufacturing processes. Whether you are in metalworking, stone processing, or even intricate artistry like jewelry making, investing in high-quality resin bonded diamond wheels can improve productivity and yield precise, high-quality results.