Introduction to Repair Electrical Cord

Repairing an electrical cord can seem daunting, yet it is a cost-effective way to extend the life of your devices. From household appliances to full-on industrial machinery, the importance of maintaining electrical cords cannot be overstated. A damaged cord can lead to potential hazards, including electrical shocks and fire risks. Understanding how to repair electrical cords properly can save both time and money while ensuring that you maintain safe operational standards.

Types of Electrical Cord Repairs

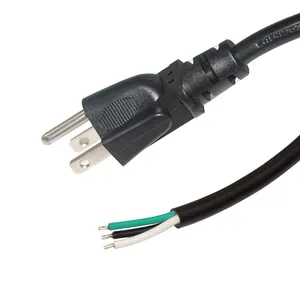

- Splice Repair: This method involves cutting out the damaged section of the cord and connecting the two ends using connectors. It's suitable for minor damages.

- Connector Replacement: If the damage is located near the plug or device end, replacing the connector can be an efficient solution.

- Rewiring: For cords with multiple strands that are frayed or exposed, rewiring a new section may be necessary to ensure safety and functionality.

- Heat Shrink Tubing: This involves covering spliced or repaired sections of the cord with heat shrink tubing for added insulation and protection.

Function, Feature, and Design of Repair Electrical Cord

- Functional Purpose: The primary function of a repair electrical cord is to restore integrity and safe use of electrical devices.

- Features:

- Durability: Modern repair cords are made to resist wear and tear, ensuring longevity.

- Flexibility: A good repair cord maintains flexibility to navigate different environments.

- Compatibility: Many repair cords are designed to be compatible with a range of devices, making them multifunctional.

- Design Considerations: Factors such as gauge thickness, insulation type, and color coding make these cords more user-friendly and safer for various applications.

How to Choose the Right Repair Electrical Cord

- Determine the Voltage Requirements: Ensure that the repair cord can handle the voltage of your devices.

- Check the Gauge: Choose a gauge appropriate for the current draw you expect; thicker cords can handle more current without overheating.

- Material Selection: Look for cords with quality insulation, preferably made from rubber or PVC for flexibility and resistance to abrasion.

- Length Matters: Consider the length needed for your specific application to avoid strain on the connectors.

Applications of Repair Electrical Cord

- Home Use: Repair electrical cords are widely used to fix frayed cords for appliances like toasters, irons, and vacuum cleaners, enhancing safety in the domestic sphere.

- Industrial Applications: In the manufacturing sector, repairs on heavy machinery cords ensure minimal downtime and maintain productivity.

- DIY Projects: Hobbyists often need repair cords for various electronics or projects, showcasing their versatility in different fields.

- Professional Electricians: Electricians carry repair cords as essential tools for immediate fixes and support in customer establishments.