(3500 products available)

Reinforcement bar benders have the crucial job of bending tough steel bars known as rebar. These bars are often used in concrete and construction projects. A general classification of rebar benders can be as follows:

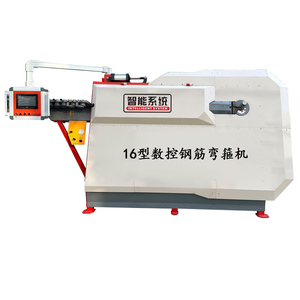

CNC Rebar Bender

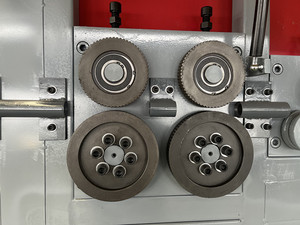

A CNC rebar bender machine uses computer control for bending reinforcement bars. This enables it to easily bend various rebars with precision accurately, hence allowing for quick changes, easy handling, and high production efficiency. A CNC rebar bender has a few parts, like the main control unit, which is protected from any harsh environment. Some may have a touchscreen, SQL system, and bending program database, while others have a bending schedule to make changes easier. The bending arm and head may come in different styles for specific designs. Generally, these machines come with a protective cover so users can be safe from risks.

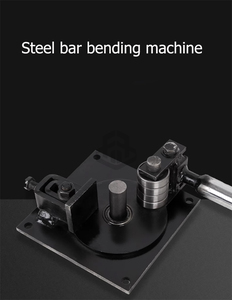

Manual Rebar Bender

Manual rebar benders are versatile, efficient, and cost-effective machines that bend rebar as required for various construction and architectural applications. Operators use handles on the machine to control the bending process. This machine has some limitations, like being physically demanding and the results lacking in accuracy.

Electric Rebar Bender

This machine is powered by electricity and uses an electric motor to bend the rebar. It may have foot pedal control, allowing operators to use both hands while working. Some styles have a speed control function to adjust bending speed. An electric rebar bender, like the manual machine, has some limitations, like being unable to bend rebar of different grades and diameters.

Hydraulic Rebar Bender

This bender uses hydraulic force to bend the reinforcement bar. It may have a portable foot pedal or stand alone, making it suitable for various applications. Bending different shapes is possible because this machine can easily bend rebar bars with different grades and diameters. However, one major drawback is that it can only bend in a single direction.

Gasoline Rebar Bender

This is a portable machine powered by gasoline. It offers bender reinforcement bar capabilities in remote areas lacking electricity. The operation is smooth and efficient, allowing bends to be made without straining. Some benders may have a dual mode to operate on gasoline and diesel.

Some common features of rebar bend machines are as follows:

Operating Range

The operating range shows the size and thickness of the rebar that the bending machine can work with. For example, some machines can handle rebar with a diameter of 4-18mm. Such a specification can be suitable for most construction needs.

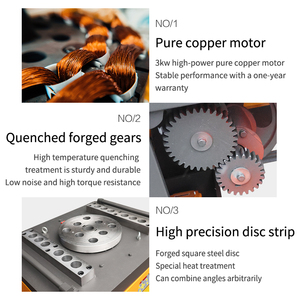

Motor Power

The bending of the reinforcement bar requires sufficient motor power. The bending machinesBar work on bending bars at a certain power. For instance, a motor power of 1.5KW might work fine for light to medium usage.

Control Method

Every rebar bending machine has a different controlling method. It can be manual controls, a up-down buttons, or digital controls with preset programs. Bending machines with program buttons are easier and quicker to use.

Accuracy and Precision

An important part of construction is accurate and precise bending of rebars. The bending machines have features that allow precise adjustments and high accuracy. This way, the bent bars fit well into the construction without errors.

For ensuring long and flawless use, the rebar bending machine needs routine maintenance. The maintenance tasks are to clean, inspect, lubricate, adjust, and repair the reinforcement bar bender equipment on a periodic basis. Practice the safe operation for both the users and the machine itself. Some general maintenance tips are as follows:

Rings and arcs can be created with the aid of the rebar bending equipment to build foundations or walls. The bar can also be easily twisted to strengthen columns. Using a digitally controlled beam, straight pieces can be precisely manufactured. Complex geometries can also be created with jigs and fixtures. Other than this, the machine can be used to produce:

Another application is the precise shaping and bending of reinforcement bars in a range of architectural and structural forms, such as:

These tips will help construction stakeholders to choose effectively the rebar bending machines for their needs.

Project Requirements Assessment

Users should determine the volume and diameter of the rebars they use in projects. If the project involves using large diameter and high volume rebar, a hydraulic or volume electric bender with good performance will be ideal. Also, the type of bend should influence the choice of machine.

Users should assess the required machine accuracy. The manual bender may be ideal when low precision will achieve project goals. However, an automatic machine that will give high accuracy to every bent is necessary if the project requires highly accurate bends.

Machine Selection

The construction stakeholders will choose a machine type after the project's need has been assessed. Choose machines that will handle the strength and diameter of steel served in the project. Large projects that do not bend rebar often may need a volume electric or hydraulic bender with good capacity for future projects. Portable machines will be used in projects where the bending has to be done on-site away from the machine's location.

Ease of Operation

Choose machines with easy control systems. Look at how easy to read the machine's display is and how intuitive the controls are. Training staff will take less time when the machine has an easy operation feature.

Safety Features

Check the machine's safety features like emergency shut-off and protective guards. These features keep the operator and job site safe from accidents and equipment damage.

Maintenance Considerations

Choose machines with good maintenance considerations. Check if it has lubrication points for regular maintenance. Find out how widespread the machine's spare parts and service support are. This factor ensures that stakeholders can get support and service fast when needed.

Energy Efficiency

Energy efficient machines help to reduce operating cost. Such machines consume less power but give optimal performance. Consider the machine's power consumption and efficiency rating when choosing a suitable bender.

Q1: What materials can the bar bending machine bend?

A1: The reinforcement bar bender is mainly designed to bend steel bars. Some machines may have attachments or modifications that allow them to bend other types of materials, such as aluminum or copper.

Q2: Can the bar bender machine create different types of bends?

A2: Yes, there are various types of bends that can be made using a reinforcement bar bender machine. They include circular or round bends, angled bends, and coiled or spiral bends, among others.

Q3: What is the maximum bending capacity of the bar bender machine?

A3: Different bar bender machines have different maximum bending capacities. It can bend bars of different diameters and thicknesses.

Q4: Does the machine offer a precise control mechanism?

A4: Yes, most bar bending machines have control mechanisms that allow users to bend bars at specified angles with high precision. The controls can be digital, numerical, or manual.

Q5: Is it possible to modify or attach the machine to perform other functions?

A5: Many bar bending machines are designed to be modified or equipped with attachments to perform additional tasks such as milling, drilling, or notching.