Types of RC Semi Trucks and Trailers

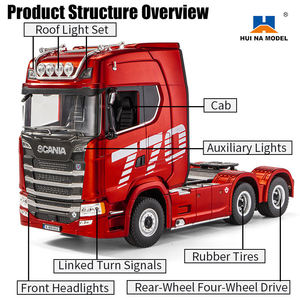

RC semi trucks and trailers are sophisticated remote-controlled vehicles that replicate real-world commercial transportation. These detailed scale models feature realistic suspension systems, authentic tires, and meticulously crafted truck bodies. The chassis consists of a sturdy frame, axles, and suspension components, all powered by either electric batteries or fuel engines. Advanced control systems allow for precise remote operation, while scaled accessories like functional lighting and authentic paint schemes enhance realism.

Enthusiast Tip: When entering the RC semi truck hobby, consider starting with an electric-powered model for easier maintenance and operation before advancing to more complex nitro-powered versions.

RC Semi Truck Power Systems

Electric-Powered RC Semi Trucks

Electric RC semi trucks operate using rechargeable battery technology. These models offer several advantages for both beginners and experienced hobbyists.

- Battery Options: Typically use LiPo (Lithium Polymer) or NiMH (Nickel-Metal Hydride) batteries

- Performance: LiPo models deliver higher speeds and extended run times compared to NiMH variants

- User Experience: Quieter operation, simpler maintenance procedures, and more precise speed control

- Best For: Beginners, indoor operation, and environments where noise is a concern

Nitro-Powered RC Semi Trucks

Nitro-powered RC trucks utilize specialized fuel mixtures to deliver a more authentic experience with unique performance characteristics.

- Fuel Composition: Typically 20-30% nitromethane, 70-80% methanol, and 5-10% lubricants

- Performance: Higher top speeds, extended run times, and more dynamic power delivery

- Operation: More complex engine management with realistic engine sounds

- Best For: Experienced hobbyists seeking authentic engine sounds and higher performance

RC Trailer Varieties

| Trailer Type | Design Features | Primary Use Cases | Advantages |

|---|---|---|---|

| Lowboy Trailers | Low deck height, multiple axles (2-3) | Hauling construction equipment, heavy machinery | Easier loading/unloading, accommodation for taller equipment |

| Flatbed Trailers | Flat, unobstructed surface without walls/roof | Oversized cargo, construction materials, machinery | Versatile loading options, forklift accessibility |

| Container Trailers | Specialized design for shipping containers | Freight transport, intermodal shipping simulation | Realistic port operations, varied design options |

| Tanker Trailers | Cylindrical tank design | Simulating liquid cargo transport | Unique appearance, specialized RC trucking niche |

| Refrigerated Trailers | Insulated box design, cooling unit replica | Simulating temperature-controlled shipping | Detailed exterior features, realistic appearance |

Specifications of RC Semi Trucks and Trailers

Understanding the technical specifications of RC semi trucks and trailers is crucial for both operation and customization. These specifications determine performance capabilities, compatibility with accessories, and overall user experience.

Scale

RC semi trucks come in various scales including 1:10, 1:14, 1:16, and 1:18, representing the size ratio compared to real trucks. Larger scales (1:10, 1:14) offer more detail and realism, while smaller scales provide greater portability and often lower costs.

Popular choice: 1:14 scale offers excellent detail while remaining manageable

Power System

Electric systems typically utilize LiPo (Lithium Polymer) batteries for superior performance. Nitro-powered models use specialized fuel mixtures for authentic engine performance and sound. Battery capacity (mAh) directly impacts run time between charges.

Tip: Higher mAh ratings provide longer operating sessions

Transmission System

RC semis feature either shaft-driven or belt-driven transmission systems. Shaft-driven systems offer better durability and torque transfer, while belt-driven systems provide smoother operation and often quieter performance.

Chassis

The chassis serves as the foundation for all components. Designs include tub chassis (integrated, single-piece) and exo (external) chassis styles. Material options typically include reinforced plastic, aluminum, or steel components.

Suspension

RC semi trucks utilize either independent or solid axle suspension systems. Independent suspensions offer better performance on uneven terrain, while solid axle designs provide stronger load-bearing capabilities and simpler maintenance.

Wheel Size

Common wheel sizes include 1.9", 2.2", and 2.5" options. Larger wheels provide better ground clearance and obstacle management, while smaller wheels offer improved precision for detailed maneuvering.

Body Style

RC semi trucks come in cabover (flat front) and conventional (extended hood) designs. Body style affects weight distribution, aerodynamics, and the truck's overall appearance and scale authenticity.

Lighting Systems

Many models feature functional LED lighting systems including headlights, taillights, marker lights, and even cabin illumination. Advanced models may include programmable lighting sequences for enhanced realism.

Important Note: Always verify component compatibility when upgrading or replacing parts. Mixing scales or incompatible components can lead to mechanical issues and reduced performance.

Maintenance of RC Semi Trucks and Trailers

Proper maintenance is essential for maximizing the lifespan and performance of your RC semi truck and trailer. Following a regular maintenance schedule helps prevent costly repairs and ensures reliable operation.

| Maintenance Task | Frequency | Tools Required | Importance |

|---|---|---|---|

| General Inspection | Before/After Each Use | Visual inspection | Critical |

| Complete Cleaning | After Every 3-5 Uses | Soft brushes, compressed air, microfiber cloths | High |

| Lubrication of Moving Parts | Monthly | RC-specific lubricants, precision oilers | High |

| Tire Inspection & Maintenance | Every 5-10 Uses | Tire gauge, replacement tires | Medium |

| Electrical System Check | Monthly | Multimeter, electrical contact cleaner | High |

| Battery Maintenance | After Each Use | Battery charger, storage containers | Critical |

| Hardware Tightening | Every 5 Uses | Precision screwdriver set, hex keys | Medium |

Essential Maintenance Practices

Regular Inspection & Cleaning

Perform thorough visual inspections before and after each operation session. Look for loose components, wear patterns, and potential failure points. Regular cleaning removes performance-degrading dirt and debris while allowing for closer inspection of components.

Pro tip: Use soft brushes and compressed air to clean hard-to-reach areas without damaging components

Proper Lubrication Protocol

Apply appropriate lubricants to all moving parts including bearings, axles, and drive components. Use lubricants specifically designed for RC vehicles - avoid household oils which can attract dirt or damage plastic components.

Warning: Over-lubrication can attract dust and create performance-degrading buildup

Electrical System Care

Regularly inspect all wiring, connections, and electrical components for wear, damage, or corrosion. Clean connectors with electrical contact cleaner to maintain optimal conductivity. Store batteries according to manufacturer specifications to maximize lifespan.

Tool Maintenance

Maintain a dedicated set of tools for your RC maintenance. Keep tools clean, organized, and in good condition. Quality tools reduce the risk of stripping screws or damaging components during maintenance procedures.

Seasonal Maintenance Tip: Before storing your RC semi truck for extended periods, perform a comprehensive maintenance service including thorough cleaning, fresh lubrication, and proper battery storage. This prevents deterioration during storage and ensures your truck is ready for operation when the season returns.

How to Choose RC Semi Trucks and Trailers

Selecting the ideal RC semi truck and trailer combination requires careful consideration of multiple factors. Whether purchasing for personal use or resale, understanding these key selection criteria will help you make an informed decision.

Target Market Assessment

Understanding the intended user is crucial for selecting appropriate models:

- Children: Prioritize models with simplified controls, durable construction, and safety features

- Beginners: Look for entry-level electric models with moderate speeds and user-friendly controls

- Enthusiasts: Consider higher-performance models with advanced features and customization options

- Collectors: Focus on scale accuracy, detail level, and authentic replication of real trucks

Brand Reputation & Support

Established brands often provide significant advantages:

- More reliable quality control and performance consistency

- Better availability of replacement parts and accessories

- Stronger customer service and warranty support

- Established community resources and modification guides

- Higher resale value and market demand

| Selection Factor | Considerations | Importance Level |

|---|---|---|

| Performance Features | Speed, power, control precision, battery life, run time | High |

| Construction Quality | Materials, assembly precision, durability, water resistance | Critical |

| Scale Accuracy | Detail level, proportions, authentic features | Medium-High |

| Parts Availability | Ease of finding replacement components | High |

| Price-to-Value Ratio | Overall value considering features, quality, and price | High |

| Upgrade Potential | Compatibility with performance upgrades and accessories | Medium |

| Controller Quality | Range, responsiveness, ergonomics, features | Medium-High |

Buying Tip: Consider purchasing an RC semi truck with a trailer as a complete kit initially. This ensures perfect compatibility between components and provides a solid foundation for future customization or upgrades as your skills and interests develop.

DIY Repair and Replacement Guide

Many common issues with RC semi trucks and trailers can be resolved through simple DIY repairs. Following this systematic approach can help diagnose and resolve problems efficiently.

Step 1: Problem Identification

Conduct a thorough assessment to pinpoint the specific issue affecting your RC semi truck or trailer:

- Test all functions systematically to isolate the problem

- Check for visible damage or loose components

- Listen for unusual sounds during operation

- Verify battery charge and electrical connections

- Consult owner forums or manufacturer resources for known issues

Step 2: Tools and Parts Acquisition

Gather all necessary components before beginning repairs:

- Acquire genuine replacement parts when possible for optimal fit and performance

- Assemble appropriate tools including precision screwdrivers, hex keys, and pliers

- Prepare a clean, well-lit workspace with sufficient room

- Consider obtaining a repair manual or online tutorial specific to your model

- Organize small parts containers to prevent loss during disassembly

Step 3: Repair Implementation

Execute repairs methodically to ensure proper resolution:

- Document the disassembly process with photos for reference during reassembly

- Work systematically, removing only necessary components

- Inspect related components for additional wear or damage

- Follow torque specifications to prevent over-tightening

- Apply appropriate lubricants to moving parts during reassembly

Step 4: Testing and Verification

Thoroughly test the repair before returning to full operation:

- Perform initial testing at reduced speed/load

- Verify all functions operate correctly

- Listen for any unusual noises that may indicate incomplete repairs

- Gradually increase to normal operating conditions

- Monitor repaired components during the first few uses

Safety Warning: Always disconnect power sources before performing repairs on electrical components. For nitro-powered models, ensure the engine is cool and fuel system is properly secured before beginning maintenance.

Frequently Asked Questions

High-performance RC semi trucks offer several significant advantages:

- Enhanced Speed and Power: Premium models deliver faster acceleration and higher top speeds

- Superior Handling: Better suspension systems and chassis design provide more precise control

- Increased Durability: Higher-quality components withstand more rigorous use and impacts

- Extended Runtime: More efficient power systems and larger batteries offer longer operating sessions

- Greater Detail: High-end models typically feature more scale-accurate details and finishing

- Better Upgrade Potential: Premium platforms often support more extensive customization options

RC semi trucks are available for operators of all experience levels:

The RC semi truck market includes models specifically designed for beginners, featuring:

- Simplified Controls: Basic transmitters with intuitive input mechanisms

- Moderate Speeds: Power systems calibrated for manageable performance

- Durable Construction: Reinforced components that withstand learning mistakes

- Stability-Focused Design: Weight distribution and suspension tuned for predictable handling

Advanced users typically prefer models with more sophisticated features and higher performance capabilities. Many enthusiasts start with beginner-friendly models and progressively advance to more complex systems as their skills develop.

Effective maintenance requires a consistent routine:

- Regular Inspection: Check all components for wear, damage, or loosening before and after operation

- Cleaning Protocol: Remove dirt, dust, and debris using appropriate tools (compressed air, soft brushes)

- Proper Lubrication: Apply suitable lubricants to moving parts according to manufacturer recommendations

- Battery Care: Follow charging best practices and proper storage procedures

- Hardware Maintenance: Periodically check and tighten all fasteners using appropriate tools

- Storage Considerations: Store in climate-controlled environments away from extreme temperatures and humidity

- Preventative Replacements: Replace wear items before they fail completely to prevent cascading damage

Following manufacturer-specific maintenance guidelines and establishing a regular maintenance schedule significantly extends the operational life of RC semi trucks and trailers.

RC semi truck operation requires attention to several safety considerations:

- Operational Area: Use in appropriate spaces away from pedestrians, pets, and traffic

- Signal Integrity: Maintain clear line-of-sight between transmitter and receiver

- Battery Safety: Follow proper charging protocols and inspect batteries for damage

- Nitro Fuel Handling: Store fuel properly and refuel in well-ventilated areas (for nitro models)

- Weight Considerations: Adhere to manufacturer weight limits for trailers and cargo

- Age-Appropriate Use: Ensure operators are of suitable age for the specific model's complexity

- Environmental Awareness: Consider weather conditions and terrain suitability

Always read and follow the manufacturer's safety guidelines specific to your RC semi truck model. Proper safety practices enhance enjoyment while preventing accidents and damage.