(1106 products available)

Racket molds are made using different materials, each with unique properties. These mold types influence the racket's performance, weight, and durability.

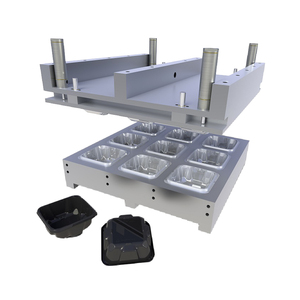

Aluminium Molds

Aluminum molds for rackets are economically feasible and widely used for initial production. They have good thermal conductivity to ensure even resin distribution during composite layup. However, aluminum's lower durability makes it suitable for short-volume production runs.

Steel Molds

Steel molds offer superior durability and are resistant to wear, making them ideal for long production runs. Due to their strength, they are suitable for complex mold designs. However, the high cost and extensive lead times make them less favorable for small-scale production.

Copper Beryllium Molds

Known for exceptional thermal conductivity, copper beryllium molds maintain temperature control even under high-pressure scenarios. This material supports consistent resin flow and curing. Although expensive, they perform well in high-volume settings, especially with challenging thermosetting composites.

Composite Molds

Composite materials like carbon fiber are lightweight yet strong in construction. They are increasingly chosen for their ability to provide complex geometries without the weight of metal molds. While less durable than steel, this option is valuable for low-cost production.

Electroformed Nickel Molds

Electroformed nickel molds excel in producing intricate patterns with superior surface finishes. Applied as a thin layer on a master mold, they are light but durable with even heat distribution. Their cost-efficiency for medium runs makes them ideal for detailed rackets.

Thermoplastic Molds

Fast, flexible, and lightweight, thermoplastic molds suit rapid prototyping and short production cycles. Easy to modify, they adapt quickly to design changes. While not fitting for long-term production due to less heat resistance, they assist in early-stage development and testing projects.

Customization of molds allows racket manufacturers to create unique rackets that meet specific functional and aesthetic requirements.

Material Customization

Different materials, such as aluminum, steel, and composites, are chosen for molds to enhance durability, thermal conductivity, and precision. Each material is selected based on properties needed for specific racket designs, ensuring the mold creates accurate and long-lasting rackets.

Surface Finish

The dictionary finish, such as polish, texture, or etching, affects the racket's grip and aesthetic appeal. Surfaces are refined to provide distinct finishes that improve user hold and design attractiveness, aligning with brand identity and performance requirements.

Temperature Control Features

Molds include temperature control mechanisms, like cooling channels, to regulate heat during the manufacturing process. This control ensures proper resin curing in composite rackets, preventing defects and maintaining material integrity, essential for peak performance in various environments.

Customization of Mold Components

Mold parts, including cores, cavities, and inserts, are tailored to produce specific racket shapes. Adjusting these components ensures precise replication of intricate design elements, vital for consistency in high-quality production while accommodating unique custom orders.

Durability and Wear-Resistant Coatings

Adding coatings to molds, like chrome plating or nitride, enhances longevity and resistances. These coatings prevent wear from frequent usage, maintaining the accuracy of the mold over time. Durable molds ensure consistent production quality, crucial for meeting demand reliably.

Production Efficiency

The efficient design of racket molds allows mass production, saving time and labor costs. This efficiency leads to high output with less manual intervention, enabling businesses to meet large market demands and increasing overall profitability more quickly.

Cost-Effective Manufacturing

With the initial investment, durable molds reduce long-term production costs. Often, steel or beryllium molds enable repeated use without degradation. Economically, they lower material wastage and defects, allowing net savings and enhanced cost competitiveness in the market.

Product Consistency

Consistent products are made using molds, ensuring each racket is identical in quality and performance. This reliability builds the brand's reputation and customer trust. Consistent production decreases variations, which helps avoid costs tied to damaged or returned items.

Expanded Design Capabilities

Advancement in mold technology permits intricate designs and varied materials. This capability aids brands in developing innovative rackets that attract customers, allowing possible expansion into premium markets. More design elasticity improves attractiveness and revenue-earning potential in a competitive field.

Durability and Return on Investment

Highly durable molds provide extended usage without replacement, increasing ROI over time. The frequent rackets of long-lasting molds ensure returns with minimal reinvestment. Businesses value this durability as it leads to sustained production without stopping due to mold wear.

Material Selection

Mold materials need high strength, such as steel or aluminum, with great durability and thermal conductivity for even heat distribution. For example, beryllium copper molds offer excellent wear resistance, while lightweight carbon fiber composites work for less demanding applications.

Dimensional Precision

Precise dimensional control is mandatory for producing identical rackets. Maintain tolerances within ±0.01 mm to ensure consistency in shape and size. Apply precision machining techniques to achieve smooth surfaces that guide accurate resin flow during the racket's molding process.

Cooling System

Develop an effective cooling system within the mold to minimize the cycle time. Integrate channels that circulate coolant, such as water or antifreeze, to rapidly cool the resin during the setting process. This rapid cooling preserves the mold's shape without deformation.

Surface Finish

Decide on the mold's exterior surface finish. Select options between glossy for a sleek look and rough for better grip. Surface texturing may also offer unique design aspects. Textures and finishes influence how the final racket's grip feels and looks to the user.

Mold Release System

Install a reliable mold release mechanism to easily separate the racket from the mold post-curing. Popular choices include mechanical ejectors or chemical release agents. Proper releases avoid damage and ensure clean extraction, preserving the molded racket's integrity.

A1: A racket mold is a hollowed form used to manufacture the various parts of a sporting racket, like tennis or badminton, mainly intended for mass production.

A2: The molds are made of steel, copper beryllium, or aluminum. Each material offers varying benefits in terms of heat conduction, detail precision, strength, and mold longevity.

A3: By coating with chromium, nitride, or other hard materials, durability increases, and resistance to wear extends, allowing the mold to maintain a high production quality for an extended time.

A4: Racket molds are made using machining where precision-cut tools create the desired shape through blending, which deposits material layer by layer, resulting in the mold.

A5: Yes, if a mold is cleaned with a gentle solvent after each use, proper wear is prevented. If it's lubricated with a suitable release agent before every use, the mold's life can maximize.