All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(2955 products available)

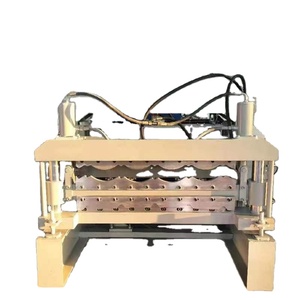

Machines used to roll form R panels are available in two key types: the single-station R panel roll forming machine and the multi-station R panel roll forming machine.

Single-Station R Panel Roll Forming Machines

The single-station R panel roll forming machine has a compact design and takes up less floor space. This machine is also easy to operate. Operators can quickly learn how to use the machine without going through lengthy training. Despite these benefits of low space use and ease of operation, the single-station machine is limited in what it can do. It can only roll panels into one specific shape. Also, panel changes are not fast or easy to do.

Multi-Station R Panel Roll Forming Machines

The multi-station R panel roll forming machine is more versatile than the single-station machine. It can create different panel shapes by changing the forming stations. It also works faster and more efficiently by processing multiple panels at the same time. But with all its good points, the multi-station forming machine requires a large area for installation. It uses more space than the single-station model. Controls for the multi-station machine are also more complicated and may need some staff training to use properly. Even though it takes up more work space and is harder to operate, this machine provides high production and great flexibility. It can meet diverse needs by quickly changing to produce various types of R panels.

R panel roll forming machines have various applications in business settings. Here are some ways that companies are currently using the machines to manufacture R panels.

When purchasing R panel roll forming machines for resale, buyers should look for features that improve their sales potential. Firstly, they should select machines with multiple refining stations. Such machines can produce panels of varying widths. Furthermore, they can manufacture multiple styles, thereby meeting diverse client requirements.

Secondly, buyers should find roll forming machines with fast production speeds. Such machines will enable them to produce more R roof panels within a short period. Additionally, buyers should consider machines that have automatic and programmable control systems. Such systems will streamline operations and reduce labor costs. Buyers should also get machines with easy-to-use interfaces. Machines with user-friendly interfaces are easy to set up, operate, and maintain. Therefore, they reduce downtime and training costs.

Moreover, buyers should look for machines that are compatible with a variety of materials. Such machines will give their customers the flexibility to choose different materials for their R roof panels. Buyers should also opt for machines that come with additional accessories, such as hydraulic systems and automatic stackers. These accessories enhance the functionality of the roll-forming machine. Also, they improve efficiency and productivity.

More importantly, buyers should get machines that have quick-change systems for easily replacing the rolls. Such systems will enable their customers to adjust production quickly and respond to market changes efficiently. Buyers should also look for machines that come with comprehensive manuals and training support. In this way, they will offer their customers adequate maintenance and technical support. Finally, buyers should choose R panel roll-forming machines build with durable materials. Such machines will have an extended lifespan and minimal maintenance requirements.

Q1: What material can an R panel roll forming machine use?

A1: In general, an R panel roll forming machine can be compatible with several materials. This includes cold-rolled steel, aluminum alloy, galvalume steel, galvanized steel, etc. Yet, for optimal performance and results, it is crucial to choose the correct material.

Q2: Does the R panel roll forming machine require special installation?

A2: Usually, a simple R panel roll forming machine does not require special installation. However, some complex or large machines may need it. They might require additional installation for specialized electrical or mechanical connections, or custom foundations and mounts.

Q3: What are the safety features of the R panel roll forming machine?

A3: The safety features of the R panel roll forming machine can vary. However, many machines typically come with a safety cover, an emergency stop button, and a safety interlock, etc.