(1135 products available)

A quick release safety locking pin is a versatile, valuable, and widely used component in different industries such as aerospace, motorsports, construction, marine, and manufacturing. Below are some of the common types of quick release safety locking pins.

R-Pin Quicks Release Locking Pins

R pin quick release locking pins are commonly used in low-load applications. This type of locking pin features a cylindrical body with an inserted handle forming the letter R or R clip. The pin is pushed into the detent or anchor point and secured by the R clip. To remove the pin, the R clip is lifted and the pin is pushed out. Despite their simplicity, safety is provided as the pin cannot easily disengage without the manufacturer's intention.

Cotter Pin Locking pins

Cotter pin locking pins are often used to secure axe heads, wheels, and various agricultural implements. This type of locking pin consists of a small metal pin, often made of stainless steel, brass, or aluminum, that comes in bent U shapes with two extended tails. To secure a fixture or coupling, the cotter pin is inserted through the pin hole. The extended tails are then bent back against the hilt of the pin to provide additional security. One notable aspect of cotter locking pins is their shape, which resembles a 'U'. This unique design allows for easy installation and removal, making them suitable for applications where quick access is required.

Cross Locking Safety Lanyard Pins

The cross-lane safety locking pin is designed to offer more security and prevent accidental disengagement. It is similar to the standard locking pin, but it has a cross-shape locking mechanism that 'crosses' over the pin, securing it with a lanyard. This option is particularly useful for heavy-duty applications in machines and tools in the construction industry. One of the main advantages of this type of locking pin is that it can withstand greater impact and load. Additionally, this type of locking pin is available in different sizes and weights.

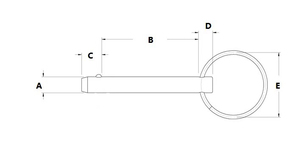

Locking Pin with Ring

The locking pin with ring is a metal pin featuring a circular attachment for easy removal. This type of locking pin is suitable for quick attachment and detachment, as it allows for one-hand operation. The ring design adds an extra level of security, preventing accidental disengagement during operation. Furthermore, this type of locking pin is ideal for securing objects onto ropes, chains, or belts. Because of its versatility, it can be used in different activities such as hiking, camping, outdoor sports, and fishing activities.

Safety locking pins offer several specifications crucial for their performance, versatility, and safety.

Materials

The materials used in safety locking pins, such as stainless steel, alloy steel, and carbon fiber, offer various levels of strength, durability, and corrosion resistance, making them suitable for a wide range of applications in different industries.

Size and Diameter

The specific dimensions, including length, size, and diameter, affect the pin's compatibility. This makes it suitable for various applications, allowing the quick-release safety locking pins to provide secure locking mechanisms across different equipment and industries.

Load Capacity

The locking pins can support high load capacities without bending or breaking. This is particularly beneficial in heavy-duty applications like construction equipment, aerospace machinery, and automotive industry, where reliable locking mechanisms are essential for safety and performance.

Operating Temperatures

Quick-release safety locking pins have an excellent operating temperature range (-20 to 100 degrees Celsius). This means they can efficiently lock and secure equipment in extreme temperature conditions without compromising their performance. Therefore, this feature makes the pins suitable for use in various industrial environments with demanding temperature requirements.

Maintenance of safety quick release pins is essential to ensure their longevity and reliable performance. Here are some tips regarding the maintenance of safety pins:

Quick release safety pins are applied in various industries as they ensure safety when holding the machinery parts and components. Below are some applications of quick release pins.

Automobile Industries

In the automobile industry, safety locking pins are applied in assembly lines. These are used by the workers to hold fixtures, jigs, and tools that assist in the production and vehicle assembly. Also, quick-release safety pins can be found in various vehicles, such as motorcycles. The pins are used to secure the body panels and ATV seats. Components that need to be frequently accessed can be easily removed for maintenance or repair.

Sports Industries

In sports industries, the safety locking pins are commonly used in team sports like rugby or football. They secure goals or movable posts in place. During training sessions or when athletes are off the field, the coaches use safety pins to secure and lock equipment such as athletic bags and bicycles.

Aerospace Industries

Aerospace industries use locking pins a lot during aircraft manufacturing and maintenance. They are used to secure access panels, control surfaces, and rupture discs. Also, locking pins are used in the assembly of drones. The pins secure various components like propellers, electronics, and payloads.

Construction Industries

Quick release safety locking pins can be applied in the construction industry to secure scaffolding components like frames and planks. They are also used in heavy machinery like excavators, loaders, and cranes. This is because quick pins allow for fast and efficient equipment attachment and detachment.

Entertainment Industry

In the entertainment industry, quick-release safety pins are frequently used in events such as concerts or festivals. The pins are used to secure lighting rigs, banners and stage set-ups. In film production, the quick-release pins are used to secure props such as vehicles or safety equipment that require quick assembly or disassembly.

When shopping for quick release safety lock pins, it is important to look beyond the aesthetics or the price. Consumers are only safe when they get the right type of safety locking pin for their specific application. This starts with researching the supplier to make sure they supply high-quality products that meet international standards.

Moreover, buyers should be aware of the different types of quick-release pins to know what their equipment or application requires. Knowing the load weight and capacity requirements of specific equipment can also help in pin identification. Buyers should also know the material composition of each quick safety pin so that the best-fitting one for an application is chosen.

If purchasing safety release pins in bulk, it would be a good idea to do a sample test first. This will better help to understand the product and its features and see if it meets the locking requirements of an application. Conducting a sample test also makes it easier to gauge the level of customer satisfaction buyers are likely to get, should the safety locking pins be resold in retail.

Conducting a sample test also helps buyers choose safety locking pins with distinct features that are most desirable for a particular industry or application. When buying in bulk, requesting customizations such as packaging, color, or logo design is also possible. From product-specific customizations to branded packaging, there are several ways to make a product-grade A for retail buyers. When buying in bulk, it makes sense to ask for any customization that can help enhance brand awareness and improve customer loyalty.

Finally, if unsure about a particular product or supplier, always ask. Asking questions to clear any doubt is a good way to ensure a safe, smooth, and pleasant shopping experience. Use filters and sort tools to help refine searches and locate products of interest quickly and easily.

Q: Are safety pins as strong as regular pins?

A: Safety locking pins are stronger than standard pins. Regular pins may malfunction when subjected to heavy pressure, while locking pins are designed to hold object tightly and cannot come apart easily.

Q: Do users need locks with safety pins?

A: In most cases, locks are not necessary when using safety pins. They are designed to hold objects tightly and cannot come apart easily without user interference. Users can quickly release them when they want to release or join objects.

Q: Can safety pins get stuck?

A: Unfortunately, this is possible under certain circumstances. Using safety pins correctly can get stuck. For instance, if they are regularly used in a high-friction environment or exposed to corrosive materials, they may get stuck. Using worn-out safety pins can also cause them to get stuck. This is because the locking mechanism is damaged, making it less capable of unpinning smoothly.

Q: How do quick release pins work?

A: Quick release pins, also known as locking pins, are designed with a mechanism that allows users to easily and quickly join or unjoin components. They consist of a pin that user inserts through the hole of two parts to join them together. Once the user is ready to disassemble the components, they pull the ring or lever. This action retracts the pin's head, releasing it from the hole.