(1183 products available)

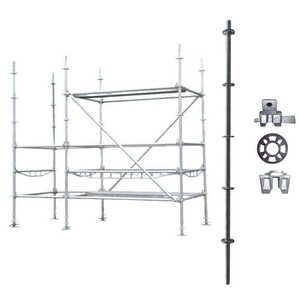

Scaffolding is a temporary structure that supports a building during construction. It is used in all construction projects, from building homes to high-rise buildings. This structure is usually made of metal, wood, or a combination of both. Scaffolds are placed around a construction site to help workers reach higher areas and complete their tasks efficiently and safely. Quick-fix scaffolding is an excellent example of a supportive structure. It is a temporary framework that allows for the construction of buildings, repairs, or maintenance. It consists of multiple tubes and beams that support a work surface. Here are some types of quick-fix scaffolding:

Single Scaffolding

Single quick-fix scaffolding consists of standards, ledgers, braces, and ties. It is used for wall support during construction, repair, or maintenance. The wall and single-sourced scaffolding standards are fixed to the ground, while ledgers are horizontal support bars.

Double Scaffolding

This type of quick-fix scaffolding is commonly used in masonry work. It consists of two rows of standards placed on the opposite sides of the structure. The double scaffolding is independent of the wall it supports and is best suited for use in situations where the wall is too weak to support a single scaffolding.

Steel Scaffolding

This type of quick-fix scaffolding is usually made of steel or iron. Its components, such as standards, ledgers, and transoms, are connected using clamps and fittings. The structure is then assembled and disassembled at the construction site. Steel quick-fix scaffolding is durable, resistant to rust and corrosion, and can carry heavy loads.

Aluminum Scaffolding

Scaffolding metals can also be made from aluminum. This type of quick-fix scaffold is lightweight and easy to move from one place to another. Aluminum scaffolding is also resistant to rust, making it suitable for different working environments.

Kwikstage Scaffolding

This is a popular type of quick-fix scaffolding in the world. It is made of steel and has a bolt and nut connection system. Its components are assembled using a spigot, a tube, and a fitting. The standards are usually 1.5 meters high, and the ledgers are 2.5 meters long. The Kwikstage scaffold is easy to erect and dismantle and provides excellent stability and support.

Birdcage Scaffolding

This quick-fix scaffolding consists of vertical standards and horizontal ledgers that form a rectangular frame. It is supported by two sets of standards placed parallel to each other. The birdcage scaffold is stable, rigid, and suitable for indoor use. It is ideal for work on high ceilings or structures like tanks and chimneys.

Here are some common features of quick-fix scaffolding.

Quick Assembly

This scaffolding is a modular system; thus, its components are easily connected to each other using couplers like the built-in ledgers and transoms. This makes the assembly and disassembly of quick-fix scaffolding easy and straightforward. This quick assembly does not require expert labor, making this scaffolding a preferred option for many.

Adjustment

Quick-fix scaffolding can be adjusted in height and level to suit various construction needs. This is done using adjustable base plates and couplers. This feature allows quick-fix scaffolding to be used in different construction projects regardless of the project height and terrain level.

Stability

Stability is a defining feature of quick-fix scaffolding. It is stable and robust, with a rigid framework of tubes and strong couplers that can withstand harsh site conditions. This is enhanced by the use of diagonal braces and tie bars, which ensure the scaffolding is balanced and evenly distributed with weight. This stability makes quick-fix scaffolding safer, as it reduces the risks of falls and collapses.

Durable Material

Quick-fix scaffolding is made of durable materials such as high-strength steel or aluminum. This material is resistant to corrosion, weathering, and rust, which ensures extended service and repeated use.

Versatility

This type of scaffolding is used in various construction projects, including residential and commercial building construction, maintenance, and industrial work. This versatility is enhanced by its ability to be customized, adjusted, and extended to meet different project requirements.

Enhanced Access and Mobility

Quick-fix scaffolding offers enhanced access and mobility, which improves work efficiency. It has a platform that is wide and textured, with anti-slip properties that increase worker's safety. Its height and level are easily accessible and adjustable, while its open structure allows easy movement of workers and materials.

Quick-fix scaffolding provides temporary support to buildings under construction or renovation. Its application is in various industries, including:

Construction

Every construction project requires the quick-fix scaffold to support the crew during building and provide a safe working platform. The scaffold is easy to assemble and disassemble, making it ideal for construction sites. Its adjustability allows it to provide the necessary support at different building heights. The robust design of the quick-fix scaffold can support more than one person and heavy construction materials.

Shipbuilding

The maritime industry uses quick-fix scaffolds to support crew members during ship construction and repairs. The scaffolds provide a safe working platform in hard-to-reach areas, enabling the crew to carry out their duties efficiently. The quick-fix scaffolds are ideal for shipbuilding since they are resistant to rust and corrosion.

Industrial plants

Industrial plants use scaffolds to support workers when installing machinery, performing maintenance, or carrying out inspections. The quick-fix scaffold provides a safe platform for workers to carry out their tasks, especially in high or hard-to-reach areas. Its robust design ensures it can support the crew and any additional materials needed for the task.

Oil and gas

Quick-fix scaffolds are extensively used in the oil and gas industry. They support workers during the construction of pipelines, storage tanks, and refineries. The scaffolds are also useful during maintenance and inspection of oil rigs and other structures. Their high load-bearing capacity and stability ensure that workers are safe and the oil and gas industry runs smoothly.

Utilities

Quick-fix scaffolds provide temporary support when utility poles or structures are installed. They also assist workers in maintenance tasks, such as inspecting and repairing overhead lines or transformers. The adjustability feature of quick-fix scaffolds makes them ideal for use in utility maintenance and installation since they can be adjusted to fit different heights and terrains.

Event setup

Event organizers use quick-fix scaffolds to support stages, lighting rigs, and other structures in concerts, exhibitions, and other events. The quick-fix scaffold is easy to assemble and disassemble, making it ideal for temporary setups. The scaffold provides a safe platform for construction and can be customized to fit different event requirements.

Choosing the right kind of quick-fix scaffolding can be challenging, especially if it’s someone’s first time. Here are some things to consider before purchasing:

Scaffolding Type

Scaffolds come in different types, such as modular or ring scaffolding, which consists of components that are assembled based on the construction project. One can opt for either a single or double scaffolding, which is used for brickwork and masonry. The temporary support scaffolding is also another type, which is used to support structures under construction. Therefore, it’s important to choose a type that fits the project.

Material

The material used to fabricate the scaffolding tubes is also an important factor to consider before making any purchase. This is because the material can affect the weight, durability, and cost of the quick-fix scaffolding. Commonly used materials include steel, aluminum, and bronze.

Project Height

The height of the project is an important factor to consider when choosing a quick-fix scaffold. This is because different types of scaffolds are designed for different heights. For example, some scaffolds are designed for low-height projects, while others are meant for high-height projects.

Weight Capacity

Another factor to consider when choosing a quick-fix scaffold is its weight capacity. It’s important to ensure that the scaffold can support the project's weight. This includes the weight of the workers, materials, and any additional equipment that will be used on the scaffold.

Regulatory Standards

It is important to ensure that the chosen quick-fix scaffold meets all the necessary regulatory standards. This is important for the safety of everyone working on the project. Additionally, it ensures that one does not incur any costs from not adhering to the legal requirements.

Portability

If the construction project requires moving the scaffold to different locations, it is important to consider its portability. Some scaffolds are lightweight and easy to move, while others are more robust and require transportation.

Assembly and Disassembly

Some scaffolds are more complex and require a professional to assemble and disassemble them. However, others are simple and can be assembled without any help. Therefore, it is important to consider this when choosing a quick-fix scaffold.

Q: What are the weight limits for quick fix scaffolding?

A: Each type of quick-fix scaffolding has weight limits. Standards determine the weight limits of each scaffolding. In general, single scaffolding carries a load of up to 2kn/m2. Double or putlog scaffolds can support up to 3kn/m2. These are just averages. The actual weight each can carry varies based on the material used to make the scaffolding, its design, and the manufacturer.

Q: What industries use quick-fix scaffolding?

A: Almost all industries that need construction or maintenance use quick-fix scaffolding. This includes the construction industry, oil and gas, power and energy, manufacturing, infrastructure, mining, and more.

Q: Are there any safety certifications for quick-fix scaffolding?

A: There are no specific certifications for quick-fix scaffolding. However, all types of scaffolds have safety standards and guidelines that manufacturers must follow when making them. These are international standards, so they vary from one country to one country.

Q: What are the maintenance requirements for quick-fix scaffolding?

A: Quick-fix scaffolding does not have high maintenance needs. It only requires basic care to keep it in good working condition. This includes regular inspections, cleaning, and storage. It's important to note that the maintenance requires technical knowledge. Therefore, it's best to leave the maintenance of scaffolds to professionals.