All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(156 products available)

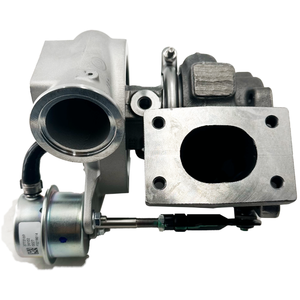

The turbine housing of a turbocharger is referred to as turbine housing. It is the portion of the turbocharger that houses the turbine blades. The turbine blade spins in the housing when exhaust gas flows through the housing. The turbine housing's design is a critical component of a turbocharger because it directly influences the turbo's performance. The turbine housing comprises the inlet and outlet. The inlet receives the exhaust flow, while the outlet directs the exhaust flow to the engine. The turbine housing's precision is critical for effective exhaust management and engine performance in general.

The turbine housing's design is a critical component of a turbocharger because it directly influences the turbo's performance. The turbine housing comprises the inlet and outlet. The inlet receives the exhaust flow, while the outlet directs the exhaust flow to the engine. The turbine housing's precision is critical for effective exhaust management and engine performance in general.

There are different types of precision turbine housings. They include:

Single Scroll Precision Tururbine Housing

Twin Scroll Precision Turbine Housing

V-Band Precision Tururbine Housing

Flanged Precision Tururbine Housing

Divided Precision Tururbine Housing

Undivided Precision Turbine Housing

Cast Iron Precision Tururbine Housing

Stainless Steel Precision Tururbine Housing

Aluminum Precision Tururbine Housing

Material:

The precision turbine housing is made of various materials, such as cast iron, stainless steel, and Inconel. Each material has its properties and advantages that can be used in different situations. For example, cast iron is strong and inexpensive. It is often used for housing made in large quantities. At the same time, stainless steel is known for its corrosion resistance and durability. Inconel is a superalloy that can withstand extreme temperatures and pressures. It is suitable for high-performance turbochargers.

Design:

The precision turbine housing is designed to optimize the flow of exhaust gases to the turbine wheel. It is usually shaped like a spiral or a cone. The housing has an inlet where exhaust gases enter and an outlet where they exit. The housing guides the exhaust gases from the inlet to the turbine wheel.

Size:

The size of precision turbine housing can vary depending on the specific application and requirements. It is typically measured in terms of diameter and length. The size of the turbine housing affects the flow of exhaust gases and the performance of the turbocharger.

Cooling:

Some precision turbine housings have cooling features, such as water or oil channels. These channels allow coolant to flow through the housing, helping to dissipate heat and maintain optimal operating temperatures. Cooling is especially important in high-performance applications where heat generation is significant.

Precision turbine housing requires regular maintenance to ensure optimal performance and durability. Here are some general maintenance tips:

Regular Inspection:

Users should check the turbine housing regularly for signs of wear, cracking, or damage. They should also check the inlet and outlet ports for blockages or restrictions that could affect exhaust gas flow.

Cleaning:

Over time, carbon deposits and other contaminants may accumulate in the turbine housing, affecting its performance. Clean the housing periodically using appropriate cleaning agents and tools. A wire brush or scraper can remove stubborn deposits, while a suitable solvent can dissolve softer deposits.

Lubrication:

The moving parts of the turbine housing may require occasional lubrication to ensure smooth operation. Use a suitable high-temperature lubricant and apply it sparingly to the bearings and other moving components.

Following Manufacturer's Recommendations:

Users should always follow the maintenance schedule and guidelines set by the precision turbine housing manufacturer. This includes using the recommended lubricants, cleaning agents, and any other specific maintenance requirements.

Choosing the right precision turbine housing can be a bit of a challenge. Here are some tips and tricks that can help make the process easier.

Tools needed are:

Follow these steps:

Q1: How should I choose a turbine housing?

A1: Choose a turbine housing based on the size of the turbocharger and the specifications of the engine. Opt for a housing that matches the turbo shaft diameter to ensure a proper fit.

Q2: What is the significance of turbine housing in a turbocharger?

A2: The turbine housing is crucial because it affects the turbo's efficiency and the engine's performance. A well-designed housing can improve exhaust flow and reduce back pressure.

Q3: Can one use a larger turbine housing?

A3: Using a larger turbine housing can prolong turbo lag while potentially increasing top-end power. It is essential to consider the trade-offs before making any modifications.

Q4: What is the difference between cast iron and precision turbine housings?

A4: Cast iron turbine housings are more durable and better at withstanding high temperatures. In contrast, precision turbine housings are lighter and can improve turbo response times.

Q5: What maintenance does the turbine housing require?

A5: Regular inspections and cleaning of the turbine housing are essential to remove any built-up debris or soot. Replacing worn or damaged gaskets and fittings is also necessary to maintain a good seal.