Introduction to Precast Concrete Sections

Precast concrete sections are engineered components crafted in controlled environments before being transported to construction sites for assembly. This innovative method of construction not only enhances structural integrity but also expedites project timelines. With a variety of forms and applications, precast concrete sections are a cornerstone of modern building and infrastructure projects.

Types of Precast Concrete Sections

Precast concrete sections come in several types, each designed for specific applications. Understanding these types can guide you in selecting the right solution for your project:

- Wall Panels: Vertical structures used for buildings and insulation.

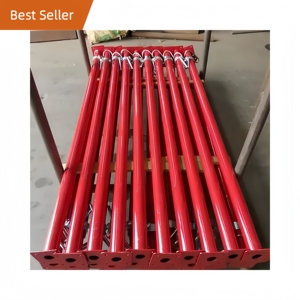

- Beams and Columns: Essential for supporting loads across vast distances in commercial installations.

- Slabs: Horizontal elements that form floors and ceilings, providing durability and strength.

- Stairs and Landings: Precast sections that save time and labor on-site while ensuring safety and compliance.

Applications of Precast Concrete Sections

The versatility of precast concrete sections allows for their use in a multitude of settings:

- Commercial Construction: Often used for office buildings and shopping malls due to their strength and design flexibility.

- Residential Projects: Ideal for multifamily units where speed of construction is critical.

- Infrastructure Development: Used in bridges, tunnels, and roadways, providing durability against environmental factors.

- Industrial Applications: Perfect for factories and warehouses that require robust structural components.

Features and Advantages of Precast Concrete Sections

Precast concrete sections provide numerous features and advantages that make them a preferred choice for builders and architects:

- Quality Control: Manufactured in a controlled environment, ensuring consistent quality and reduced defects.

- Durability: Resistant to wear and tear, moisture, and pests, making them suitable for long-lasting construction.

- Cost-Effectiveness: Reduced labor and time on-site lead to overall savings in construction costs.

- Design Flexibility: Available in various shapes, textures, and finishes to meet specific aesthetic requirements.

- Speed of Installation: Quick assembly on-site reduces project timelines significantly, allowing for faster occupancy.