All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(132977 products available)

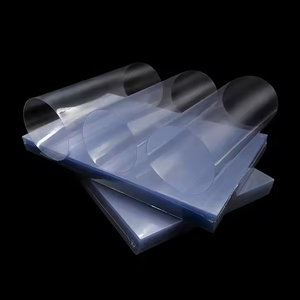

Laminate types, such as adhesive laminate, download interactive laminate, and pressure-sensitive pp lamination, enhance document storage and usability. Each type is designed for specific applications, increasing flexibility in various environments.

Adhesive Laminate

Adhesive laminate involves two layers of plastic bonded together with an adhesive layer. This laminate is designed for long-term document protection: waterproofing, shielding against UV radiation, and adding durability. It is best suited for documents requiring permanent protection, such as important historical archives and maps. In this context, the double-sided adhesive pp laminate enhances the durability and long-term preservative qualities of vital documents, rendering them waterproof and resistant to fading due to UV exposure.

Polypropylene Laminate

Polypropylene laminate is a popular option for those looking to waterproof their materials at a lower cost. It is light, flexible, and tear-resistant, making it ideal for menus, maps, and outdoor use brochures. Propylene lamination's resistance properties allow it to endure moisture, making it a perfect fit for materials exposed to various elements.

Pressure-Sensitive Laminate

Pressure-sensitive laminate has a sticky layer that bonds to its surface when firmly pressed, as its name implies. This laminate stands out from others because it can be easily positioned and removed without permanent sticking. It is most appropriate for temporary usage and short-term documents, such as promotional posters that might need to be revised or relocated regularly. As temporary protection requires flexibility, pressure-sensitive pp laminate is suitable for files exposed to varying conditions and in frequent rotation.

The design of pp lamination contributes toward enhancing the effectiveness and appeal of laminated products.

Varied Thicknesses

PP lamination is available in various thicknesses, depending on the type of item laminated, from lightweight paper to thicker cardboard or plastic. Different types of PP laminate can be manufactured with lamination ranging from 1.5 to 10 mils. Selecting the proper thickness for your documents depends on the required stability and flexibility. Thin laminates (around 1.5-3 mils) work well for flexible items like business cards or bookmarks that need to bend without cracking. For items requiring more rigidity, such as ID cards or coasters, thicker laminates (5-10 mils) provide the stiffness and border protection from wear, tear, and moisture. When designing laminated products, careful consideration of laminate thickness guarantees that the final product meets aesthetic and functional demands.

Textured Finishes

The finish of the PP laminate is also very rich in variety. Laminates can have concrete finishes, soft-touch finishes, or linen-type textures for additional grip and a tactile appeal. These textured finishes are also excellent at hiding surface defects on low-quality printing. The rise in demand for tactile experiences in the design is aimed at making textured laminates a practical solution wherever they are used.

Custom Cut and Shape

The design of PP lamination also permits individualized cutting and shaping. In the case of laminated menus or brochures, unusual shapes can be designed for superior visibility and appeal. The flexibility of PP laminates allows the creation of distinct designs that differ from standard laminated products. This quality is especially useful for marketing materials and packaging, where such products considerably improve the appearance of items.

Pp lamination is extensively applied across industries to protect, enhance, and elevate' aesthetic value. Below are some common cases where PP lamination is valuable:

PR Materials

PP Lamination is frequently used in the printing of brochures, business cards, and flyers for use in advertising. Laminating these items makes them appealing, strengthening their purpose as marketing instruments. A restaurant menu laminated with pp will have a long life in the hands of customers and while in use. Besides protection, lamination adds to the textural appeal of the menu.

Learning Tools

PP Lamination is widely used in the educational industry for flashcards, charts, and other learning aids. The interactive flashcards, for instance, are sturdy and can be flipped, providing longevity for repetitive handling. They are also easy to clean, an important factor in classroom hygiene and management.

ID Cards and Badges

The id badge, personal identification number, and other related products are typically laminated using pp. Such protection ensures these devices are waterproof, tear-proof, and fool-proof. This p lamination is crucial in environments where these devices are constantly in use.

Art and Collectibles

PP lamination is popular among artists and collectors of prints, paintings, and drawings. Artworks are shielded from deleterious elements, such as moisture and sunlight, and an added layer of protection to preserve their original condition forever. Similarly, sports collectibles or trading cards get laminated to keep them in desirable condition for many years.

To understand laminate types, such as adhesive laminate, interactive laminate, and pressure-sensitive pp lamination, which enhance document storage and usability, it is essential to discuss specifications and maintenance.

Specification

Polypropylene (PP) lamination is a popular choice among many due to its multiple advantageous properties. First of all, it comes in different thicknesses to suit the laminated product's desired firmness or flexibility. Typically, these thicknesses change in mils, with the most common being the 1.5-3 mils for daily use items like menus or cards and 5-10 mils for those requiring additional strength. Another factor contributing to the laminate's strength is the heat sealing method employed in its application, which merges the laminate with the surface. This bond is quite solid, ensuring long-lasting protection. It's also worth mentioning that PP Lamination is even more eco-friendly than before because it is often manufactured with recyclable thermoplastics, which reduce the impact on landfills and thus allows for greater sustainability.

Maintenance

The care of laminated products is indeed easy, especially considering their nature. However, for items under thicker laminates, cleaning is often restricted to cosmetic, superficial cleaning. For instance, hand wiping with a damp cloth to eliminate filth or marks is often recommended. However, for thinner laminated materials, further measures may be required: Regular inspection of materials with such laminate for signs of wear that necessitates immediate replacement. Another plus is that laminated materials do not require additional protective coatings or treatments, commonly associated with other methods of enhancing material longevity.

A1: The primary benefit of pp lamination is that it adds a layer of protection to items that shields them from moisture, sunlight, and frequent handling, thus enhancing durability.

A2: Pp laminate is made from polypropylene, which makes it especially resistant to adverse weather and bending. It is thicker and has more strength than other types of laminates.

A3: Yes, pp lamination is made from polypropylene, a recyclable plastic. It is advised to check local recycling programs to see if they accept pp laminated items.

A4: Industries such as printing and publishing, education, and even art gather the benefits of pp lamination for the protection and longevity of their materials.

A5: Yes, pp lamination adds a glossy or matte finish to items, which can improve their visual appeal and make them more attractive to customers.