All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(1674 products available)

A polyurethane liquid waterproofing membrane is a liquid that is applied to surfaces to create a continuous membrane. This membrane provides waterproof protection. It is usually applied on flat or low-slope surfaces. There are different types of polyurethane liquid waterproofing membranes, including:

Moisture-Curing Polyurethane Membrane

This membrane is designed to cure when it comes into contact with moisture. This makes it ideal for use in humid or wet environments. It is durable and forms a strong bond when cured. The curing process is also quick, and the membrane has excellent adhesive properties. However, it requires careful application. This is because the curing process may be affected by the temperature and humidity levels.

Non-Curing Polyurethane Liquid Membrane

Just like the name, this membrane does not cure. Instead, it creates a liquid-applied waterproofing membrane that cures through evaporation. It is mostly used in dry climates. The membrane creates a thick film that is also flexible. It is easy to apply and cures quickly. The non-curing membrane is also resistant to UV light. However, it is only suitable for applications on surfaces that are clean and dry. Its performance may be affected if there is a strong wind during the application period.

Single Component

A single-component polyurethane waterproofing membrane is easy to use. It is suitable for use in different waterproofing applications. The membrane becomes liquid when applied, and it cures to form a solid, waterproof barrier. It also bonds well to different substrates. However, the curing process is slow when the temperatures are low.

Two-Component Polyurethane Liquid Membrane

This type of waterproofing membrane consists of two components. These are the isocyanate and resin components. The components need to be mixed in the right ratio for the membrane to be applied. The mixing process allows for better control of viscosity and curing time. It also produces a membrane with higher tensile strength and durability. However, it requires special skills to mix and apply the membrane. The process is also time-consuming.

The polyurethane liquid waterproofing membrane has some applications. It is used in construction, automotive, and aerospace industries. Here are some common use scenarios.

Construction

It is used to create waterproof barriers in buildings. For example, basements, foundations, roofs, and parking lots. The liquid membrane is applied to the surface of concrete walls and floors. This prevents water from seeping through and flooding a basement. It is also applied to roofs to create a seamless membrane that protects water from rain and UV rays. Additionally, it is used in parking lots to protect water from rain water.

Balconies and terraces

The liquid waterproofing membrane is applied to balconies and terraces. This protects water from rain, and UV degradation. It also prevents water from damaging the underlying structure. For example, water can damage concrete, wood, or other materials. It also helps to ensure water is properly drained off the surface.

Deck coating

Liquid polyurethane waterproofing membranes are used as deck coatings. For example, they are applied to pedestrian decks and other structures. The coatings provide a durable, traffic-bearing surface. They also protect the deck from water damage, UV degradation, and abrasion. The coatings are available in different colors and textures. This helps to enhance the aesthetic appearance of the structure.

Landfills and waste containment

Polyurethane waterproofing membranes are used in landfills. They create impermeable barriers in waste containment structures. This prevents the leachate from contaminating the groundwater. The membranes are ideal for such applications because they can be bonded to geotextiles. They also have a high puncture resistance and durability.

Agricultural applications

The waterproofing membranes are used in agricultural applications. For example, they are used in ponds and reservoirs. They help to reduce water loss through seepage. This helps to conserve water and improve irrigation efficiency. The membranes are also used in the construction of tunnels and other underground structures.

It's important to consider a few factors when choosing the right waterproofing membrane for a project. Some of them are outlined below.

Project Requirements

The first thing to consider is the specific needs of the project. This involves evaluating elements like the location, the kind of surface that needs to be waterproofed, and the level of moisture that is expected. For example, if the surface is horizontal, a liquid waterproofing polyurethane membrane should be considered. However, if it's vertical, a waterproofing coating should be preferred.

Climate Conditions

Climate conditions have a significant impact on the performance of waterproofing membranes. Therefore, it is important to consider the weather patterns in the area where the membrane will be used. For example, polyurethane membranes are preferred in areas with consistent rainfall because they cure to form a robust, waterproof barrier. On the other hand, in extremely cold or windy areas, a different membrane may be more suitable.

Surface Type

The type of surface that requires waterproofing affects the performance of the membrane. It's important to choose a membrane compatible with the surface material. For instance, polyurethane membranes work well on concrete and masonry surfaces. Moreover, it is important to consider the texture of the surface. A rough surface may require a thicker membrane application for complete waterproofing.

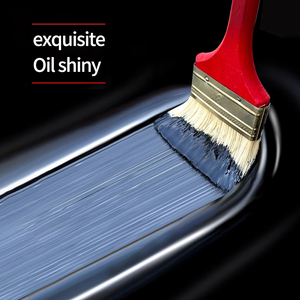

Application Method

It's important to consider the preferred method of application. For instance, some membranes are applied using a spray technique, while others are rolled or brushed on. Additionally, some membranes require specialized application equipment, which can be an extra cost to the buyer.

Substrate Preparation

The substrate must be well prepared before a waterproofing membrane is applied. This ensures that the membrane adheres properly and offers adequate waterproofing. However, the preparation process can be affected by different factors, such as the type of membrane used and the surface material. Therefore, buyers should consider the substrate preparation requirements before choosing a waterproofing membrane.

Q1: What are the surface preparation requirements for liquid membrane application?

A1: The surface should be clean, dry, and free of contaminants. It should also be roughened to promote adhesion. Any sharp protrusions should be removed, and cracks or holes should be repaired.

Q2: What safety precautions should be taken when applying liquid membranes?

A2: Apply in well-ventilated areas. Use personal protective equipment like gloves, masks, and goggles to prevent skin contact and inhalation.

Q3: What is the difference between polyurethane and other waterproofing membranes?

A3: Polyurethane is liquid-applied, creating seamless, durable, and flexible membranes. Other types, like sheet membranes, are pre-fabricated and require adhesive or heat to install.

Q4: Can polyurethane waterproofing membranes be applied on wet surfaces?

A4: No, polyurethane membranes should be applied on dry surfaces to ensure proper adhesion and curing.

Q5: How long does the polyurethane waterproofing membrane last?

A5: When properly applied and maintained, it can last up to 10-15 years or longer.