All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(1951 products available)

A polyurethane liquid membrane is a waterproof coating applied as a liquid and then dries to form a flexible, durable membrane. It is used for waterproofing and protecting surfaces in construction and other applications. There are different types of polyurethane liquid membranes, including:

Based Polyurethane Liquid Membrane:

These membranes are known for their ease of application and excellent waterproofing capabilities. They are often used in residential projects or areas requiring a high degree of flexibility. They are usually cheaper compared to other types. They are easily applied using a brush, roller, or spray. They have a high degree of flexibility and excellent waterproofing capabilities. However, they have a lower UV resistance and are more prone to solvent evaporation during the curing process.

Polyurethane Liquid Membrane Coating:

These coatings provide a tough, abrasion-resistant membrane. This makes them ideal for high-traffic areas or locations subject to constant wear and tear. They have a thicker application, creating a more durable membrane. They offer excellent waterproofing and UV protection. However, they are less flexible and require a primer for proper adhesion.

Moisture-Cured Polyurethane Liquid Membrane:

These membranes cure through moisture in the air, making them suitable for application in various environmental conditions. They are often used for commercial projects due to their durability and ease of use. They cure quickly and can be applied in humid conditions. They have a very durable and chemical-resistant surface. However, they require specific surface preparation and can be more expensive than other types.

Aliphatic Polyurethane Liquid Membrane:

These are known for their excellent UV stability and longevity. They are often used in exposed areas where UV resistance is crucial. They have a long lifespan and reduce yellowing and deterioration due to UV exposure. However, they are more expensive and require skilled application.

Thermoplastic Polyurethane Liquid Membrane:

These membranes are characterized by their ability to be reprocessed by applying heat. This makes them a more sustainable option for projects requiring repairs or modifications. They allow for easy repair and modification, enhancing their sustainability. However, they require specific substrate conditions and are less common than other types.

Waterproofing:

Polyurethane liquid membranes are primarily developed for waterproofing applications. They form a seamless, durable, and flexible barrier that prevents water from seeping through. This is important for decks, terraces, roofs, and foundations. They protect buildings from water damage, which deteriorates structural integrity and mold growth.

UV Resistance:

Some polyurethane membranes have UV stabilizers. This allows them to be used in exposed areas without needing additional protective layers. UV resistance extends the membrane's lifespan and maintains its waterproofing properties.

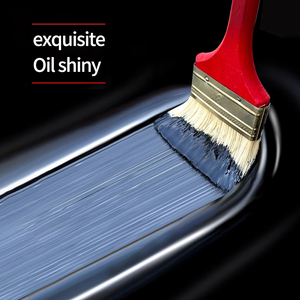

Seamless Application:

The liquid polyurethane membranes are applied as liquids. They cure to form a continuous, seamless membrane. Seamless membranes eliminate joints and seams, which are weak points in waterproofing. This creates a more effective and aesthetically pleasing waterproofing surface.

Adhesion:

Liquid polyurethane has excellent adhesion to various substrates. This includes concrete, metal, wood, and bituminous surfaces. Good adhesion ensures a long-lasting waterproofing barrier. This withstands movement and stress without delaminating or cracking.

Elasticity and Flexibility:

Once cured, liquid polyurethane membranes offer high elasticity and flexibility. This enables them to adapt to substrate movements due to temperature changes, structural settlements, or mechanical stresses. These membranes minimize the risk of cracking or tearing, which compromise waterproofing.

Durability and Abrasion Resistance:

Polyurethane membranes are durable. They resist punctures, tears, and abrasion from foot traffic, UV rays, and harsh weather conditions. Their durability ensures long-term waterproofing performance with minimal maintenance.

Breathability:

Certain polyurethane membranes have breathable options. These allow water vapor to escape from the substrate. This reduces the risk of condensation and mold growth, particularly in enclosed spaces like balconies and parking garages.

Thermal Insulation:

Some formulations incorporate additives that provide thermal insulation properties. These help maintain a stable indoor temperature and reduce energy costs.

A liquid polyurethane membrane is commonly used in construction and building projects. It is widely known for its excellent waterproofing capabilities and is used in various applications, including:

When choosing the right polyurethane liquid membrane for a specific purpose, consider the following:

Functionality:

Consider the polyurethane membrane's primary function. Consider membranes designed for waterproofing or those suitable for protective coatings. Waterproofing membranes are specifically made to create a water barrier. In contrast, protective coating membranes offer durability against weathering, UV radiation, and surface wear.

Substrate Compatibility:

Check whether the polyurethane membrane is compatible with the substrate material. This ensures optimal adhesion and performance. Some membranes are formulated specifically for concrete surfaces. Others can work well with different substrates like wood and metal.

Application Method:

The choice can depend on the preferred application method. Some polyurethane liquid membranes are applied using brushes or rollers. Others require spray equipment. Consider the recommended application method for efficiency and ease of use on the intended surface.

Environmental Conditions:

It's important to consider the environmental conditions where the membrane will be applied and its location. Some membranes are specially formulated for specific climates. For example, tropical climates experience more rainfall while arid climates have high temperatures and UV radiation.

Regulatory Compliance:

A buyer should ensure that the chosen polyurethane liquid membrane complies with the local building codes and environmental regulations. This is more important for commercial applications and construction projects.

Budget:

Different polyurethane membranes come with different price points. A buyer should evaluate their budget and balance the cost against the need and quality of the product. Choosing a cheaper product can lead to higher long-term costs due to poor performance or premature failure.

Brand Reputation and Reviews:

It's important to research the available brands in the market. Look for reputable brands that have produced quality products. Check the online reviews and testimonials from previous clients. This provides insight into the product's performance and reliability.

Q1: Is a polyurethane liquid membrane waterproof?

A1: Yes, polyurethane liquid membranes are waterproof. They create a continuous, seamless barrier that prevents water from passing through. This is why they are commonly used on rooftops and decks where water management is critical.

Q2: How long does a polyurethane liquid membrane last?

A2: The lifespan of a polyurethane liquid membrane depends on several factors. These include the quality of the product, the application process, and the environmental conditions it is exposed to. Generally, a well-applied membrane using quality products can last between 10-20 years. Regular maintenance can also extend its lifespan.

Q3: Can a polyurethane liquid membrane be applied on wet surfaces?

A3: No, a polyurethane liquid membrane should not be applied on wet surfaces. For optimal adhesion and performance, the surface must be clean and dry before application. This prevents the formation of bubbles or uneven surfaces.

Q4: Are polyurethane liquid membranes environmentally friendly?

A4: Polyurethane liquid membranes are not very environmentally friendly. They contain chemicals that can be harmful if inhaled or come into contact with the skin. Therefore, wearing the appropriate protective gear when applying them is important. Fortunately, many manufacturers have developed water-based polyurethane membranes that are less harmful and more environmentally friendly.

Q5: Can a polyurethane liquid membrane be repaired?

A5: Yes, a polyurethane liquid membrane can be repaired. It is important to use the same product as the original application to ensure compatibility and a seamless repair. The repair area should be properly cleaned and prepared before applying the membrane.