(5550 products available)

A polyurethane injection pump has different types based on composition. The classification includes air pumps, electric pumps, hydraulic pumps, and pneumatic pumps.

Air Pump

An air pump is a type of polyurethane injection pump that uses compressed air to inject the chemical mixture. It has a direct connection to the air compressor that supplies the needed force. The air compressor compresses the air, and then the pump propels the liquid. This pump is lightweight and simple. Therefore, it is easy to transport and use. One disadvantage, however, is that the injection pressure can fluctuate. This is due to changes in the compressor's air pressure. This phenomenon can influence the consistency of the foam produced.

Electric Pump

Hydraulic Pump

A hydraulic pump operates by using hydraulic pressure. The hydraulic fluid in this pump creates a powerful force for injection. This makes it suitable for high-performance applications that need heavy-duty use. The pump works smoothly, even with high resistance. This is due to the controlled flow of the hydraulic fluid. As a result, this ensures flawless and steady injection of the polyurethane. Although this pump provides high pressure and durability, it will need regular maintenance. This is to ensure a stable functioning of the hydraulic system.

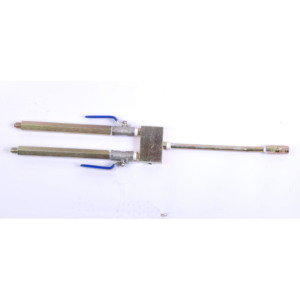

Pneumatic Pump

Pneumatic pumps transform chemical energy into mechanical force to inject the liquid. These pumps work with different air motors. It can be coupled with a ratio control box or lift cylinder. This is to suit different applications. The maintenance of the pumps is quite easy. It has low service and repair costs. However, there can be some energy loss. This is because the motor powering the pump needs compressed air.

Polyurethane injection pumps are usually characterized by their specific production parameters. Here are some key parameters along with their maintenance requirements:

Flow Rate

To ensure consistent operation, users should maintain the pump by regularly inspecting the flow control components. They should check the flow control valves, flow meters, and other relevant parts to see if they are worn out or faulty. Adjust the flow control valves as per the pump's characteristics and work requirements so as to obtain the appropriate flow. Additionally, they should monitor the actual flow rate and make timely adjustments to the control parameters based on the operating conditions to ensure the stability of the flow.

Pressure

Users of the polyurethane injection pump should pay attention to pressure sensor maintenance. They should regularly calibrate and maintain the pressure sensors to ensure accurate pressure monitoring and feedback. Furthermore, they should monitor the system's operating pressure. Take a look at the injection pressure, feeding pressure, and other relevant pressures to ensure that they are within the normal range. If there's any abnormality, users should investigate the cause and promptly address it to avoid equipment damage or quality issues.

Seal

Users should maintain the sealing components by regularly inspecting them for wear, damage, or aging. If any abnormal condition occurs, they should be promptly replaced to ensure the sealing performance and prevent leakage. Also, users should clean the sealing surfaces to remove dirt and impurities thereby ensuring good contact and sealing.

Agitation System

In the maintenance of the agitation system, users should pay attention to the inspection and maintenance of the mixing blades. They should check the stirring blades for wear, damage, or deformation, and promptly carry out repairs or replacements as necessary. Additionally, users should ensure that the drive system of the stirring system is in good condition and the transmission components are properly lubricated to ensure stable operation and effective stirring.

Construction:

Pouring of construction components like beams, columns, and foundations using a polyurethane injection pump is common. It provides support to structures and ensures that they are durable and strong.

Automotive:

The automotive industry often utilizes polyurethane injection pumps for car assemblies. This includes the helping of body panels, production of car interiors, and sealing and insulating electronic components. Pumps are also used for the injection of insulation cores in the production of automotive windshields.

Packaging:

A polyurethane injection pump is utilized for the production of protective packaging. This includes foam inserts and cushions for fragile and delicate products.

Furniture and Industrial:

In the area of furniture and industrial design, a polyurethane injection pump is used for the production of custom-made items. This includes decorative elements, furniture pieces, and industrial components. Pumps provide versatility and design freedom by allowing for the precise reproduction of complex shapes.

Wind Energy:

Wind turbine blades are produced using a polyurethane injection pump in the renewable energy industry. The turbines call for strong and lightweight blades with a high-performance standard, thus requiring the usage of the pumps for accurate molding.

Medical:

Medical devices are produced with a high level of precision using a polyurethane injection pump. Pumps are used in the molding of components related to medical devices like connectors, valves, and sensors.

Footwear:

In the footwear industry, a polyurethane injection pump is used to produce shoes, specifically athletic and casual footwear. Pumps offer flexibility, lightweight, and comfort—all characteristics that are needed in shoes.

Application Needs:

Determine the specific application requirements, including the type of material (e.g., PU, epoxy), viscosity, and temperature. Consider factors such as static mixing, spraying, or filling needs. Select a pump that meets the demands of the application.

Flow Rate and Pressure:

Assess the flow rate and pressure requirements for the intended use. Choose a pump that provides sufficient flow and pressure to achieve desired results. Consider the size and complexity of the projects.

Material Compatibility:

Ensure that the injection pump's materials are compatible with the chemicals being used. Different adhesives and mixtures may require specific material compatibility to prevent degradation or contamination.

Design Flexibility:

Consider the need for a compact and lightweight design. Such features can enhance portability, allowing for easier handling and maneuverability during injection tasks, particularly in confined or remote work areas.

Quality and Reliability:

Invest in a polyurethane injection pump that offers durability and low maintenance requirements. Opt for a reliable brand to minimize downtime and ensure consistent performance in critical injection applications.

Budget Considerations:

Evaluate the cost of the polyurethane mixing injection pump and weigh it against the features, performance, and quality it offers. Consider the long-term value it brings to the business in terms of efficiency and reliability.

Q1: What is the injection technique for polyurethane foam?

A1: The injection technique is a method used to create formed parts of polyurethane by injecting the raw material into a mold.

Q2: What are the primary components of polyurethane?

A2: The two main components of polyurethane are polyol and isocyanate.

Q3: What does the polyurethane pump do?

A3: The polyurethane pump transfers and mixes the components for injection into a spray nozzle.

Q4: What is the difference between pu and PVC?

A4: Polyurethane (PU) is elastic like rubber, while polyvinyl chloride (PVC) is rigid like plastic. Furthermore, PVC remains chemically inert throughout its life, but PU can be recycled.