(1076 products available)

Ready to Ship

Ready to Ship

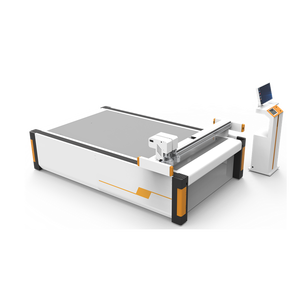

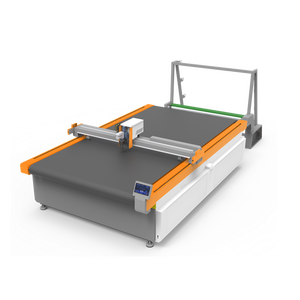

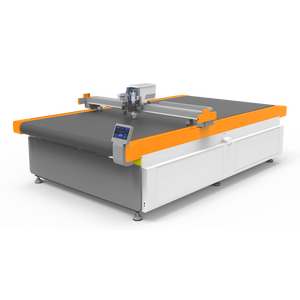

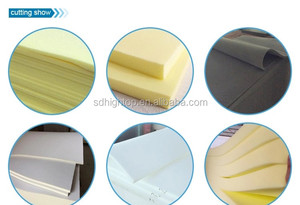

Polyurethane foam CNC milling machines have many forms to suit various foam machining required. They vary based on the polyurethane foam type they handle, the CNC milling process, and the anticipated outcome.

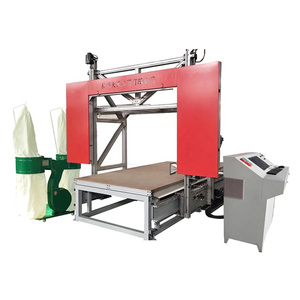

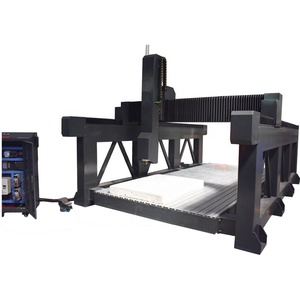

CNC routers are cutting machines that mainly shape rigid polyurethane foam. Rigid polyurethane foam is widely used in the automotive, aircraft, and building industries for insulation. CNC routers have a spindle fitted with a rotating tool that cuts out the desired form when they operate. Routing is one of the most common CNC milling methods. Routing is good for making large foam pieces or flat, detailed cuts with precision.

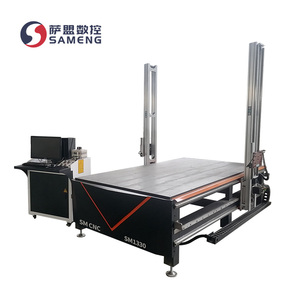

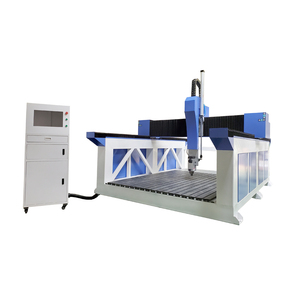

A CNC mill/cnc milling machine is good when accuracy and detailed cutting of rigid polyurethane foam are required. CNC milling machines are used to create models, prototypes, and complex components. They do this by removing material and ensuring an accurate finish. CNC mills are ideal for precise applications such as medical equipment and aerospace parts.

Users prefer a CNC lathe machine mainly for machining pieces in foam composite materials. Such projects call for a rotating workpiece and a cutting tool to generate cylindrical forms. CNC lathes are best for producing numerous identical components, such as handles, knobs, and casings since they are efficient and accurate.

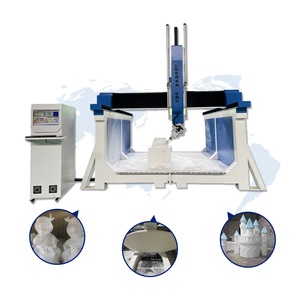

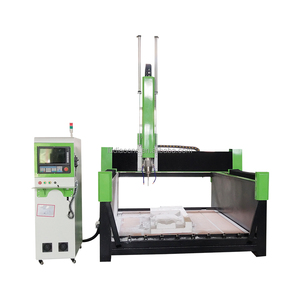

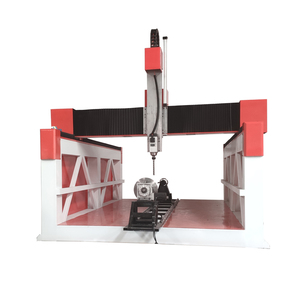

A 5-axis CNC machine can turn and tilt the cutting tool and workpiece to approach the cutting surface from five different angles. This method allows for more complex geometries and undercuts in one setup. 5-axis machines are typically used for high-precision aerospace, automotive parts, and molds in composites.

For the CNC machine to function well, its tool and work table must be made of the right material. The table and tool holder have to made from durable material, while the workpiece can be flexible PU foam.

These materials must have certain key features. They must have good properties, be reasonably easy to machine, and be able to hold the workpiece securely during CNC operations. Note the most common materials used for CNC machine working surfaces include plywood, MDF boards, aluminum, and vacuum tables designed for this purpose.

The tool wearing out from repeated cuts inside the foam also needs to be looked at. These cutting tools should be made from tough materials that can cut smoothly through foam without becoming dull too quickly. The four materials suggested for the cutting bits include:

Some recommended maintenance and quality CNCs milled tools improve longevity. They also ensure the machine continues to perform optimally. The main maintenance checkups include routinely inspecting the machine for wear and damage, lubrication of all critical moving parts, and cleaning between projects to remove debris from inside the machine. Owners are advised to spare CNC components from extreme temperatures, high humidity levels, and foam dust accumulation. All these help to make the CNC foam cutting machine last longer.

Polyurethane foam has a vast array of applications in various industries due to its versatility and cutting characteristics. CNC machining of PU foam is well-suited because it allows for high precision and consistency in shaping.

In engineering and product design, CNC-milled polyurethane foam finds application as a prototyping material. CNC Machining helps create lightweight and easy-to-manage prototypes. These prototypes are used before the final products are developed.

The aerospace and automotive industries use CNC-milled components that are lightweight and used for thermal insulation. The foam helps to insulate several airplane parts. The foam also acts as an impact absorber in some car parts.

Architectural applications include insulation panels and decorative facades. In these applications, CNC-milled polyurethane foam is used because it is a choice material. In construction, CNC-milled polyurethane foam is used to manufacture intricate false ceilings and light, insulating wall panels.

CNC-milled PU foam inserts are designed for custom protective packaging. The foam inserts provide cushioning and support for delicate electronic items, medical devices, and fragile glassware during transportation.

In furniture design, CNC machines create ergonomic seating solutions such as chairs and cushions. PU foam used in cushioning provides comfort and durability.

Prop making for theater, film, or exhibitions often requires lightweight yet sturdy materials. CNC-milled PU foam lends itself to this purpose perfectly. It can be shaped into complicated designs while remaining easy to move around.

Sports equipment such as helmets, pads, and surfboards use CNC-milled PU foam for shock absorption and safety. CNC machining foam enables the creation of precise molds for surfboards and other equipment.

Cushioning pads, backrests, and other custom medical devices that provide support and pressure relief utilize CNC-milled PU foam in the medical field. CNC allows for a precise, tailored fit for orthopedic braces and prosthetics.

Selecting a CNC machine for foam projects involves considering several key aspects. These include the CNC machine type, working area size, spindle power, and bit/tool selection.

The machine type chosen should be practical for the client's desired results. A CNC router is typically chosen for large flat sheets or simple forms. A CNC mill/ CNC Milling is for accurate prototypes or intricate shapes. If working with cylindrical items like handles, foam lathed pieces are best done on a CNC lathe. Complex designs requiring multi-angle cuts are done on a 5-axis CNC machine.

The work area should be large enough to accommodate the project. It should also leave room for adjustments and easy setup. A small CNC machine suffices for simple foam items. Larger projects like furniture or architectural models demand extensive machining space.

Spindle speed is crucial for different foam types. High-speed spindles create smooth finishes on soft foam. Rigid foam necessitates lower speeds with more robust spindle motors. The spindle should offer adjustable speeds to control the cut based on the foam's density.

CNC foam cutting bits come in varied shapes and sizes for specific tasks. They range from rough bits to slice through dense layers to smooth finishing bits for a fine surface. Keyhole bits create accurate cutouts while edge trimming bits remove excess foam around projects.

A keyholder vacuum bed maintains foam stability when cut. Keyholes offer a secure grip on the foam, preventing slips during CNC operations. Their integration improves execution speed and accuracy.

Proper software is as vital as quality hardware. Various CNC machines offer distinct compatibility with foam design and cutting program files. Pursue a machine compatible with user-end software. This will streamline project conception and execution. A known software coupled with the CNC machine minimizes operational hiccups. This ensures users can fully leverage the CNC machine's potential.

A. CNC machines have proven to reasonably efficiently work through PU foam. CNC machines have attributes that make them ideal for routing soft materials like foam. Their computer-numerically-controlled precision ensures accurate cutting without excess force.

This precision prevents foam tearing and minimizes wastage and post-processing needs. These attributes make CNC milling machines cut and sculpt foam effectively for diverse applications.

A. The CNC machine's level of precision and the project size determination mainly influences the cost. At the low end of the spectrum, small foam CNC machines are purchasable for below one thousand dollars. For a more professional-grade CNC machine, one has to pay in the region of several thousand dollars. Buying a CNC machine is just part of the price. One also has to think of expenses for machine upkeep, cutting tools, and power consumption over time.

A. CNC machines can handle most foam materials as long as they do not have a very high density. Polyurethane foam is commonly chosen due to its machinability. Machine users have found the machine quite manageably working with other soft materials like polyvinyl chloride.

A. The CNC foam milling setup is generally uncomplicated and approachable. One simply needs to prepare the foam workpiece and utilize a properly designed cutting tool. They then fix the foam to the work surface. The operator then imports the design into CNC software and makes any needed adjustments. Finally, the operator starts the machine, monitoring the process to ensure it adheres to their design specifications.