(6009 products available)

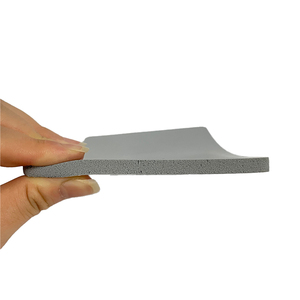

A polystyrene foam block is a rigid and lightweight material made from expanded polystyrene (EPS) foam. The blocks are usually produced in different sizes and shapes and can be used for various applications, such as insulation, packaging, construction, and modeling. The blocks are made through a process that involves the polymerization of styrene monomer with the addition of foaming agents, which creates a large number of gas bubbles that expand the polystyrene beads. These beads are then fused together through heat and pressure to form a solid block of foam.

Polystyrene foam blocks are widely used because they are lightweight, cost-effective, and have excellent thermal insulation properties. They also have high compressive strength and are resistant to moisture and chemicals. The blocks can be easily cut and shaped into different sizes and forms for various uses.

Polystyrene foam blocks are classified into two main categories: Expanded Polystyrene (EPS) and Extruded Polystyrene (XPS). Knowing the types of blocks will help buyers choose the right product for their application.

Expanded Polystyrene (EPS)

The polystyrene foam block is also known as bead foam. It is produced from foam beads that are expanded and fused together to form a block. The beads have air pockets that provide insulation. The blocks are made using a simple and cost-effective process. They can be recycled and are widely used in construction and packaging. The blocks are lightweight, have excellent thermal insulation, and are moisture resistant.

Extruded Polystyrene (XPS)

The foam blocks are made from a different process that involves extrusion. The polystyrene resin is melted and mixed with additives to create a continuous foam strand. The blocks have a denser cell structure that provides better insulation. The production process is more complex and expensive than that of EPS. However, the blocks have higher compressive strength and better water resistance. The blocks are commonly used in applications that require high performance, such as below-grade insulation and refrigerated trucks.

Other types of polystyrene foam blocks include:

Depron:

The polystyrene block is made of extruded foam and has a thin and smooth surface. It is lightweight and provides good insulation. The blocks are mainly used for model building and RC aircraft.

Styrofoam:

The blocks are made from expanded polystyrene foam. They are used for various packaging and craft projects. The blocks can be easily cut and shaped.

Neopolen:

The blocks are made from polypropylene copolymer foam. They are lightweight and have a smooth surface finish. The blocks are used for packaging applications and buoyancy aids.

Construction

Polystyrene foam blocks are widely used in construction because of their lightweight and insulating properties. Expanded polystyrene (EPS) foam blocks are used to construct foundations, walls, and even roofs. These blocks provide excellent thermal insulation, which helps to reduce energy costs. Since these blocks are used as a formwork, they create a permanent structure that is safe from water damage and is easily recyclable.

Art and Crafts

Polystyrene foam blocks are popular in the art and craft industry. Artists use them to create sculptures of different sizes and shapes due to their lightweight nature. They are also used in model making, where artists create architectural models or dioramas. Additionally, these blocks are used in schools and DIY projects to create creative projects.

Packaging

Polystyrene foam blocks are used to make custom packaging inserts to protect fragile items during shipping. They make sure goods arrive in one piece without any damage. The packaging blocks are also used to package electronics, ensuring there is no impact during shipping. Additionally, these blocks are used to package perishable items like seafood and groceries, ensuring they remain fresh during transit.

Prototyping

Polystyrene foam blocks are used in creating prototypes in the manufacturing industry. Builders and engineers use the blocks to create scale models of buildings, airplanes, and boats. The lightweight nature of these blocks makes them easy to handle.

Event Planning and Decor

Polystyrene foam blocks are used in the event planning industry. Event planners use the blocks to create large decorative displays for weddings and corporate events. These blocks can be shaped into letters, numbers, or sculptures. The blocks are also used as a base for floral arrangements and to create signage.

Consider the Block's Thermal Properties

Think about the climate where the building will be put up. If it's really hot or cold there, the foam block's insulation works should be checked out. EPS usually has good insulation for normal temps. But for extreme weather, the insulation ratings should be compared more.

Look at the Cost to See What Makes the Most Sense

Different foam blocks have different price ranges. EPS is usually more affordable. When budgets are tight, EPS might be the better pick since it saves money upfront but still meets insulation needs. The lower cost per R-value should be balanced against the project's overall goals.

Check the Block's Strength and Durability

The building's design should be thought about. Will it need more strong walls or roof supports? If so, the load-bearing needs should be met with a block that can handle loads like beams or trusses. The PSI ratings should be looked at - higher numbers mean more strength for support.

Think About the Environmental Impact

How important is being green? Some blocks are made with more recycled stuff or have less chemicals that harm the ozone. If sustainability matters, a block with eco-friendly production should be picked. The long-term planet benefits should be considered alongside the cost.

Evaluate the Construction Process

The building crew's skill level should be looked at. If they're new to foam, simpler styles like EPS that go together easily should be picked. But if the team knows their way around, more advanced ICFs could be tried too. The builder's experience should match the block's complexity. A tough block may frustrate an inexperienced crew.

Think About the Project's Time Constraints

How urgent is the building schedule? Some foam blocks go together faster than others. If time is short, a block that can be installed quickly should be picked to meet deadlines. The construction speed should be prioritized so the project stays on track.

Q: What are the common applications of polystyrene foam blocks?

A: PS foam blocks are used for insulation in construction, packaging and shipping delicate items, creating lightweight models and prototypes, and expanding agricultural storage containers.

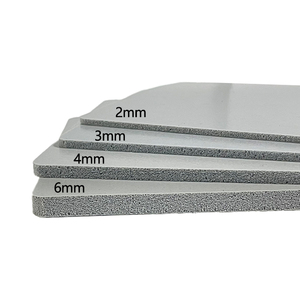

Q: What are the dimensions of a polystyrene foam block?

A: The size of a PS foam block varies greatly. For instance, the thickness ranges from 1 to 6 inches or more, while the length can be between 6 to 40 inches or more. The width is usually between 6 to 40 inches or more. However, these are not standard sizes since the blocks can be made to fit specific dimensions.

Q: How are the polystyrene foam blocks manufactured?

A: The blocks are made from expandable polystyrene (EPS) beads). The beads are exposed to steam in a molding machine, causing them to expand and fuse together to form a solid block. The blocks can also be cut from pre-expanded PS foam using hot wire cutting techniques.

Q: How should the foam blocks be stored?

A: The blocks should be stored in a cool, dry place, away from direct sunlight and heat sources. This prevents them from melting or deforming. They should also be stored on pallets to allow for proper air circulation.

Q: Are the blocks environmentally friendly?

A: The blocks are not recyclable but can be recycled. They can also be made from recycled materials. Additionally, some manufacturers produce biodegradable foam products that offer the same benefits as the PS foam blocks.