All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(1291 products available)

A polymerization reactor is a specialized chemical reactor used to manufacture a wide range of materials from one or more monomers. These reactors are typically used in the production of plastics, resins, and rubbers. One common type of polymerization reactor is the polypropylene reactor. There are two main types of polypropylene reactors used in industrial settings.

Other types of reactors used in the industry include the loop reactor and the gas phase reactor. Loop reactors are a type of CSTR that consist of a series of interconnected vessels. The vessels are used to produce polymer chains that grow and filter out of the reactor. Gas phase reactors, on the other hand, are usually fixed bed reactors. In this type of reactor, the reaction takes place on a fixed bed of catalysts. The catalysts are usually held in a vertical tube or shell. Gas phase reactors are used to make low-density polyethylene and high-density polyethylene.

Reaction volume: The volume capacity of a polypropylene reactor is typically expressed in liters or cubic meters. It can range from a few liters to several cubic meters, depending on the production scale and requirements.

Operating temperature: The operating temperature indicates the temperature range that the polypropylene reactor can achieve and maintain. It is essential to ensure that the reactor can be used within the required temperature range to meet specific production needs.

Pressure rating: The pressure rating of the polypropylene reactor refers to the maximum pressure it can withstand during operation. It is often measured in bars or MPa. The pressure rating is crucial for determining whether the reactor can handle the required pressure for the chemical reactions.

Material compatibility: The polypropylene reactor is generally compatible with various chemical substances. However, it is crucial to ensure that the reactor's material is fully compatible with the reactants and products to avoid chemical reactions or corrosion.

Regular inspection: Regularly check the overall condition of the polypropylene reactor, including the reactor body, the connection of each component, the sealing system, etc. Detect possible wear, damage, or leaks in a timely manner and perform maintenance and repairs.

Cleaning: Clean the interior of the polypropylene reactor regularly to remove residue or contaminants left after the chemical reaction. Select cleaning agents according to specific requirements and ensure thorough cleaning to avoid contamination or interference in subsequent reactions.

Replace consumable parts: Some parts of the polypropylene reactor, such as seals, gaskets, etc., are consumables and may wear out over time. Regularly inspect the condition of consumable parts and replace them in a timely manner to ensure the sealing and safety of reactor operations.

Calibration and adjustment: The polypropylene reactor is equipped with various instruments and control systems, such as temperature sensors, pressure gauges, etc. Regularly calibrate and adjust these devices to ensure their accuracy and reliability.

Lubrication and corrosion protection: For some moving components of the reactor, such as agitators, bearings, etc., carry out lubrication and maintenance regularly. This can reduce friction and wear and extend the service life of parts. Also, take effective measures to prevent corrosion of the reactor's internal and external parts in corrosive environments.

Safety system inspection: The polypropylene reactor is equipped with safety devices and systems, such as pressure relief valves, interlocks, etc. Regularly inspect and test the safety system to ensure its normal operation and reliability, thereby ensuring the safety of reactor operations.

PP reactors are widely used in various chemical manufacturing processes, such as polymerization, oxychlorination, and phosgenation. These processes require reactors to produce resins, PVC, and other chemical products.

PP reactors can be used for the treatment of sewage and industrial wastewater. This process involves chemical reactions to remove impurities and pollutants from the water.

PP reactors play an important role in the energy production process. They are commonly used in the production of natural gas, petrochemicals, and other chemical products.

PP reactors can be used in food and pharmaceutical processing. They are suitable for chemical reactions, such as the production of pharmaceutical intermediates and food additives.

PP reactors are often used in the field of environmental protection. They can be used to process and dispose of hazardous waste, turning them into safe and harmless substances.

PP reactors are widely used in academic research, such as organic synthesis, polymer chemistry, and material science. This is because they are suitable for various chemical reactions and can provide a safe reaction environment.

When choosing polypropylene reactors for sale, it is important to consider the following factors.

It is essential to consider polypropylene reactor sizes to ensure they meet the requirements of different industries. Small reactors ranging from 10 to 500 liters are suitable for small-scale manufacturing. Large reactors over 1000 liters are ideal for mass manufacturing. Their high-capacity enables them to produce a large volume of products within a short period. Medium-sized reactors with a capacity of 500 to 1000 liters are suitable for mid-level manufacturing. They strike a balance between small and large reactors.

Choose a polypropylene reactor with an efficient heat transfer system. The reactor should have an external jacket that allows users to regulate the temperature. This is important for preventing hot spots and ensuring uniform temperature distribution.

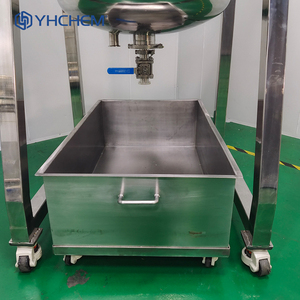

Select a polypropylene reactor with a suitable agitation system. The reactor should have a motor and impeller that can mix the product effectively. Different types of impellers are suitable for specific applications. For example, a paddle impeller is ideal for mixing high viscosity fluids and scraping the walls of the reactor. A turbine impeller is suitable for blending low viscosity fluids. Customers prefer reactors with adjustable agitation speeds. The feature allows them to optimize the mixing process according to specific requirements.

A well-designed polypropylene reactor should have a safety interlock system. The system should prevent the operator from opening the reactor when it is pressurized or at a high temperature. The reactor should have emergency stop buttons that allow the operator to stop the operation in case of an emergency. Additionally, choose a reactor with modern control systems. It should have an intuitive interface that allows the operator to monitor and adjust process parameters with ease.

The cost of polypropylene reactors is an important consideration for many customers. The price varies depending on the capacity, specifications, and brand. It is important to offer different sizes and models to meet the needs of customers with different budgets.

Q1: What sets polypropylene reactors apart from other types of reactors?

A1: Polypropylene reactors are often distinguished by their ability to withstand high temperatures and corrosive environments, making them ideal for various chemical processing applications.

Q2: What are some safety considerations when working with a polypropylene chemical reactor?

A2: Safety is a top priority when working with chemical reactors. It's important to ensure proper ventilation to avoid chemical exposure and to have adequate safety protocols and equipment in place, such as emergency showers and eyewash stations. Regular maintenance and inspections of the reactor are also crucial to identify any potential risks or issues that may arise.

Q3: What are the customization options available for polypropylene reactors?

A3: Manufacturers offer a wide range of customization options for polypropylene reactors. These may include different reactor sizes and shapes, varying temperature and pressure ratings, specialized mixing or agitation systems, control systems, and monitoring features, among others.

Q4: Are polypropylene reactors environmentally friendly?

A4: Polypropylene is considered an eco-friendly material because of its recyclability. When the time comes to dispose of or replace a polypropylene reactor, it can often be recycled and repurposed into new products. This helps reduce the amount of waste that ends up in landfills.

Q5: How can businesses ensure the optimal performance of a polypropylene chemical reactor?

A5: Regular maintenance is crucial to the optimal performance of a polypropylene reactor. This includes routine inspection of components, such as seals and gaskets, as well as cleaning and calibration of any control systems. Monitoring for any signs of wear or damage and addressing them promptly is also important to avoid costly repairs or downtime.