Types of plate rolling machine 4mm

There are several types of 4mm plate rolling machines. They can be chosen based on the design, working principle, application, and needs of the clients' business.

- Hydraulic Plate Rolling Machine: This machine controls the top roll by hydraulic cylinders, which makes the rolling force bigger. It rolls the plates into cylinders through pre-bending and rolling of the two ends. The machine has an advanced digital control system, which can roll complex cylinders with high precision.

- Mechanical Plate Rolling Machine: This type applies rolling force through gear motors. The design is traditional, and it is more suitable for rolling thin plates and materials.

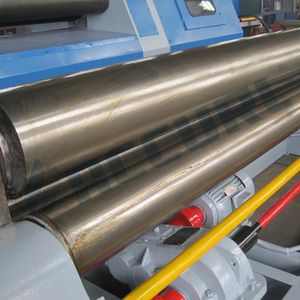

- Three-roll Symmetrical Plate Rolling Machine: This machine has two lower rolls and one upper roll that is directly above them. The upper roll is used to apply pressure to draw the plate between the lower rolls. The presses then roll the plate into a cylinder. This rolling machine is suitable for rolling plates without flanges.

- Four-roll Plate Rolling Machine: The machine has two fixed lower rolls and two movable upper rolls. The upper rolls move down and up in a vertical motion, and they can also pivot in a horizontal motion about the lower rolls. This rolling machine is suitable for rolling plates with flanges. It can also be used when less flatness is required.

- Top Roll Dropping Hydraulic Plate Rolling Machine: This rolling machine drops the top roll vertically. It is used to roll plates with small diameters. The top roll drops down, and the plate is removed horizontally.

- Pre-bending Plate Rolling Machine: This machine rolls a plate into a cylinder with a flange at one or both ends. It also pre-bends the plate edges during the rolling process.

Specifications and maintenance of 4mm plate rolling machine

Specifications

- Cylinders:The rolling machine has three cylinders. For the top cylinder, its diameter is 100-600mm, and the length is 1250-3000mm. The side cylinders' diameters are 75-175mm, with a length of 1250-3000mm. The down cilindro is 100mm, and its length is 1250-3000mm as well. For the bottom cylinder, it has the same parameters as the side cylinder.

- Rounding Accuracy: The rounding accuracy of a plate rolling machine is usually defined with the ± 1 mm. The rounding accuracy will change with different machines.

- Capacity: A 4mm plate rolling machine can bend a plate with a thickness of 4 mm. The ability of this machine is to roll plates into cylinders with a maximum thickness of 4 mm or less.

- Driving System: The driving system of the plate rolling machine includes a motor, gearbox, coupling, and a few more. In the machine, the motor provides torque and drives the reducer; then, the power is transferred to the rollers through couplings and gears.

- Voltage and Power:For a rolling machine, the voltage and power are various options like 380V, 415V, 450V, etc. And the motor power is from 2.2kw to 15kw.

- Dimensions and Weight:The dimensions and weight of the machine are various. For a machine with a length of 3000 mm, a width of 1200 mm, and a height of 1500 mm, it weighs 2.5 tons.

Maintenance

- Clean the machine:One of the key 4mm plate rolling machine maintenance tips is to keep it clean. Wipe the machine's rollers and frames with a soft, lint-free cloth after each use to prevent residue build-up. To protect the paintwork and coatings from deterioration, routinely clean the machine parts, primarily those exposed to the outside.

- Lubricate moving parts: Lubrication is essential to machine maintenance. Lubricate the moving sections, including bearings, gears, and chains, as specified by the manufacturer. Proper lubrication minimizes wear and tear, reduces friction, and extends the life of the rolling machine.

- Regularly calibrate and inspect: Through regular inspections and calibrations, the 4mm rolling machine plate's accuracy and reliability can be maintained. Set up a frequent inspection routine. Check the machine for any damage, misalignment, or wear. Make any necessary repairs right away to maintain the device's usefulness. Also, calibrate the machine routinely to ensure precision cutting and rolling. Following the manufacturer's maintenance schedule will keep the machine accurate and effective.

Scenarios of a plate rolling machine

Rolling machines are popular and widely used in various industries and applications, including construction, aerospace, automotive, shipbuilding, piping, HVAC, arts and crafts, rail transport, oil and gas, and the military.

- Construction: Steel plate rolling machines help create structural elements like arches, support beams, and columns. They accurately roll plates into shape to build roofs, facades, and bridges.

- Aerospace: Aerospace companies roll lightweight materials into cylinders for fuel tanks, pressure vessels, and jet engine parts. They use plate rolling machines to ensure that these parts meet precise weights and mild steel tolerances.

- Automotive: The Automotive Industry plate rolling machines assist in generating curved structural components for frames, chassis, and exhaust systems. Automotive engineers use plate rollers to ensure that vehicles are stable and remain functional.

- Shipbuilding: Plate rolling machines are often used to make hulls, decks, and bulkheads. These parts often need to be rolled or curved from thick plates of steel.

- Piping: Industries that deal with pipe construction often use plate rolling machines. The machines can be used to create the pipe's parts or its support for pillars.

- HVAC: HVAC manufacturers use plate rolling machines to create ducting, hoppers, transition pieces, and other components that carry warm or cool air from the central air system to various buildings.

- Arts and crafts: Artists use small plate rollers to create sculptures, jewelry, balconies, and chandeliers. The machines safely curve metal into artistic shapes.

- Rail transport: Railroads use plate rolling machines to create tracks and other transportation infrastructure. They roll the plates to design and manufacture various parts needed for a functional train.

- Oil and gas: In the oil and gas industry, plate rolling machines help produce pipelines, storage tanks, and offshore platforms that extract oil or gas from deep under the sea.

- Military: The defense industry uses heavy-duty plate rolling machines to roll armor plates and protective shields for military vehicles, naval vessels, and defense infrastructure.

How to Choose Plate Rolling Machine 4m

When shopping for rolling machines, buyers should consider machinery with specific features and capabilities that meet the needs of their target customers.

- Frequency Converter: A rolling plate machine's frequency converter controls the frequency of the electric motor driving the roller. When choosing machines for the target market, buyers should ask if the frequency converter regulates the speed of the rolling cylinders. Malls with machines can offer versatile plates that allow users to adjust the speed when rolling different types of metal plates.

- Hydraulic System: The central part of any plate rolling machine, especially large ones, is the hydraulic system. It's used to control and apply force to roll heavy metal plates. An easy choice for buyers is to get machines with quality hydraulic systems from well-known manufacturers. Customers will want machines with reliable hydraulic systems for accurate and precise metal rolling.

- Carbon Steel Rolling Capabilities: Carbon steel is an equal mixture of iron and carbon and is commonly used in the construction industry. Some commercial and industrial-grade rolling machines can only roll thin plates of carbon steel, around 3-12mm in thickness. When choosing machines for a target market, buyers should think about the type and thickness of carbon steel their customers use. If the customers use thicker and large steel plates, buyers should go for machines with robust rollers and motors.

- Stainless Steel Rolling Capabilities: Stainless steel is steel mixed with a pinch of chromium. It is used in construction, manufacture, and design for its strength and corrosion resistance. It often comes in higher gauges compared to carbon steel. The rolling machines for stainless steel are calibrated differently due to the chemical and physical composition of stainless steel, which requires a more delicate rolling process. When choosing a rolling machine that can roll stainless steel plates for their clients, buyers should ensure it has enough power to roll stiff stainless steel to the desired diameter.

FAQ

Q1: How does a plate rolling machine work?

A1: Plate rolling machines work by applying forces to flat steel plates, curving them into desired shapes. The process begins with loading the steel plate onto the machine's rolls, which then bend it by either rotating or tilting at certain angles. Several techniques can achieve this, such as hydraulic pressure or mechanical means. Fine adjustments can be made until the steel plate reaches the desired curvature and shape.

Q2: What materials can be rolled with a plate rolling machine?

A2: The materials that can be effectively rolled using a plate rolling machine include but are not limited to: carbon steel, alloy steel, stainless steel, aluminum, copper, brass, titan, and zirconium.

Q3: What is the difference between plate rolling and sheet rolling?

A3: Whether rolling plates or sheets, the goal is to curve flat materials. However, due to their inherent characteristics, different techniques may be needed to apply forces adequately. Additionally, the dimensions of the end products are not the same. Rolling sheets produce larger diameter cylinders than those produced by rolling plates.

Q4: How many rolls does a plate rolling machine have?

A4: A plate rolling machine has three or four rolls, depending on the type of plate rolling machine it is. The plate rolling machines with three rolls are the most conventional and common. They have two bottom rolls and one top roll. The top roll is movable to adjust the gap between the top and bottom rolls. The three-roll machines may efficiently roll plates into conical shapes and circular cylinders. The three-roll machines include the pyramid, cosine, and variable arc type. Aside from the three-roll machines, the four-roll plate rolling machine consists of two fixed bottom rolls and two movable top rolls. It further compounds the plate into circular shapes. The four-roll plate machine is easier to operate and offers better accuracy in rolling.