(9999 products available)

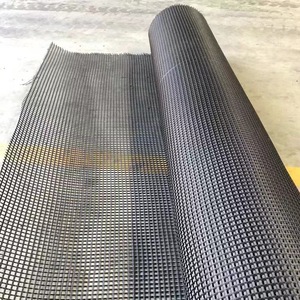

plastic unidirectional geogrid are essential components in modern construction and real estate projects, particularly in earthwork applications. These geosynthetic materials are designed to provide reinforcement and stability to soil structures, making them indispensable in various engineering and construction scenarios. plastic unidirectional geogrid are typically made from polymers such as polypropylene or polyester and are known for their high tensile strength and durability. They are commonly used in applications like road construction, retaining walls, embankments, and slope stabilization, where they help distribute loads and reduce soil erosion. As construction projects become more complex, the demand for plastic unidirectional geogrid continues to grow, highlighting their importance in achieving sustainable and long-lasting infrastructure.

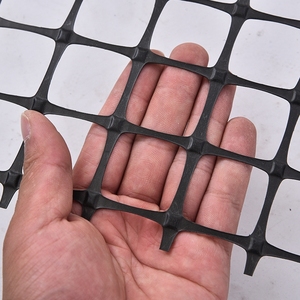

The variety of plastic unidirectional geogrid available in the market caters to different construction needs. Uniaxial geogrids are designed for applications requiring high tensile strength in one direction, making them ideal for retaining walls and embankments. Biaxial geogrids, on the other hand, provide strength in both vertical and horizontal directions, suitable for road construction and pavement reinforcement. Triaxial geogrids offer multidirectional strength and are used in projects where load distribution is critical. Each type of plastic unidirectional geogrid is engineered to meet specific requirements, ensuring optimal performance for its intended use. Additionally, the choice between woven and non-woven geogrids can impact the project's overall stability and effectiveness.

plastic unidirectional geogrid serve several crucial functions in earthwork applications. Their primary role is to reinforce soil structures, providing stability and preventing deformation under heavy loads. This reinforcement capability is achieved through their high tensile strength, which ranges from 20 kN/m to over 100 kN/m, depending on the type and application. plastic unidirectional geogrid also enhance the load-bearing capacity of soil, making them ideal for use in areas prone to erosion or instability. Features such as chemical resistance and UV stability ensure that plastic unidirectional geogrid can withstand harsh environmental conditions, maintaining their integrity over time. Furthermore, their open mesh structure allows for efficient drainage, reducing the risk of waterlogging and soil degradation.

The production of plastic unidirectional geogrid involves the use of high-quality polymers, primarily polypropylene and polyester, which are selected for their durability and strength. These materials are often treated with additives to enhance their performance, such as UV stabilizers to prevent degradation from sunlight exposure, or chemical treatments to improve resistance to environmental factors. The choice of polymer impacts the geogrid's elasticity, tensile strength, and overall performance, allowing manufacturers to tailor plastic unidirectional geogrid to specific applications. Additionally, advancements in manufacturing technology have led to the development of eco-friendly geogrids, incorporating recycled materials to reduce environmental impact.

Using plastic unidirectional geogrid effectively involves understanding their properties and application scenarios. For optimal performance, select the appropriate type of geogrid based on the project's load requirements and soil conditions. Proper installation is crucial, ensuring that the geogrid is laid flat and tensioned adequately to prevent slippage or misalignment. In road construction, plastic unidirectional geogrid should be placed between layers of aggregate to enhance stability and prevent rutting. For slope stabilization, they must be anchored securely to provide reinforcement and prevent erosion. Regular inspections and maintenance are essential to ensure the longevity and effectiveness of plastic unidirectional geogrid , particularly in areas exposed to extreme weather conditions.

Choosing the right plastic unidirectional geogrid for your construction project involves considering several factors that influence performance and suitability. One of the primary considerations is the type of soil and load conditions at the site. Different soil types require specific geogrid designs to effectively reinforce and stabilize the structure. For instance, soft or clay soils may benefit from biaxial geogrids, which provide multidirectional strength, while sandy soils might be better suited for uniaxial geogrids. Additionally, the expected load and stress levels should guide the selection process, as higher tensile strength geogrids are necessary for areas with heavy loads or frequent traffic.

Another critical factor is the environmental conditions where plastic unidirectional geogrid will be used. Consideration of factors such as UV exposure, chemical resistance, and temperature fluctuations is essential in ensuring long-term durability and effectiveness. Geogrids treated with UV stabilizers or chemical-resistant coatings are recommended for projects exposed to harsh environmental conditions. Furthermore, the choice between woven and non-woven geogrids can significantly impact the project's stability and drainage capabilities, making it crucial to assess the specific requirements of your site.

When selecting plastic unidirectional geogrid , it is essential to evaluate soil type, load conditions, environmental factors, and the specific application. Each of these elements can affect the geogrid's performance and suitability for a given project. Additionally, understanding the tensile strength requirements and drainage needs will help determine the most appropriate type of geogrid for your construction needs.

Soil type plays a significant role in determining the appropriate plastic unidirectional geogrid for a project. Different soils have varying load-bearing capacities and stability characteristics, necessitating specific geogrid designs. For example, clay soils may require uniaxial geogrids for enhanced reinforcement, while sandy soils might benefit from biaxial geogrids for improved load distribution. Understanding soil properties is crucial for optimal geogrid selection.

Yes, plastic unidirectional geogrid can be effectively used in extreme weather conditions, provided they are designed and treated to withstand such environments. Geogrids with UV stabilizers and chemical-resistant coatings are ideal for projects exposed to high temperatures, sunlight, or corrosive substances. Proper installation and maintenance are also critical to ensuring the geogrids' longevity and performance under challenging conditions.

plastic unidirectional geogrid are instrumental in promoting sustainable construction practices by enhancing soil stability and reducing the need for excessive earthmoving and material usage. Their ability to reinforce soil structures leads to more efficient land use and minimizes erosion, contributing to environmental conservation. Additionally, advancements in eco-friendly geogrid materials, such as recycled polymers, further support sustainability efforts in construction projects.

Post-installation maintenance of plastic unidirectional geogrid involves regular inspections to identify any signs of damage or misalignment. Ensuring that the geogrids remain securely anchored and tensioned is crucial for maintaining their effectiveness. In areas prone to extreme weather, periodic checks for UV degradation or chemical exposure are recommended. Proper upkeep ensures the geogrids' longevity and continued performance in reinforcing soil structures.