All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(5947 products available)

Plastic formwork plywood is an essential component in modern construction, providing a reusable framework for shaping concrete structures. Understanding its various types can help stakeholders choose the right formwork for their projects. Here are the types:

Traditional Formwork

Timber is commonly used in traditional forms, especially in India, to build walls, foundations, and other structures. This method involves pouring concrete into a mold made of wood, metal, or other materials and then removing the mold once the concrete has set.

Engineered Formwork

Engineered formwork is a system of forms that have been pre-designed and manufactured for specific construction projects. It is commonly used in large-scale construction sites where speed, efficiency, and cost-effectiveness are essential.

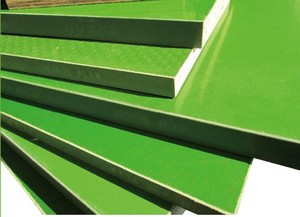

Plastic Formwork

This type of formwork involves using polystyrene plastic to construct walls, foundations, and other structures. It is a popular choice for projects requiring a quick and straightforward construction process, such as residential buildings, stormwater management systems, and foundations.

Sheathing

Sheathing is a form of wood-based concrete formwork used to create flat surfaces such as concrete slabs, walls, and foundations. It involves using plywood, OSB, or other engineered wood products supported by a frame of timber or steel.

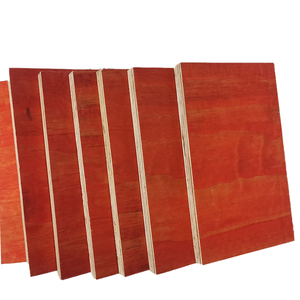

Plywood Formwork

Plywood formwork is a popular choice for concrete construction, especially in India. It involves using plywood sheets supported by timber or steel beams to create molds for pouring concrete. It is commonly used for walls, foundations, and slabs, offering a good balance of strength, rigidity, and cost.

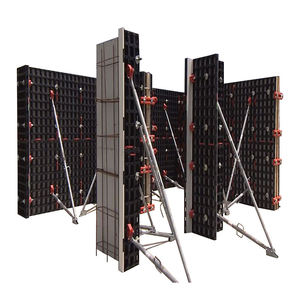

Modular Formwork

Modular formwork is a system of pre-fabricated forms that can be easily assembled and disassembled for repetitive construction tasks. It is made from materials such as wood, steel, or aluminum and is commonly used for walls, columns, and slabs in high-rise buildings and bridges.

Steel Formwork

Steel formwork is a type of engineered formwork made from steel. It is commonly used in large-scale construction sites where speed and efficiency are essential. Steel formwork is durable, reusable, and can produce smooth concrete finishes.

Aluminum Formwork

This type of formwork is made from aluminum and is commonly used in the construction of residential buildings. It is lightweight, easy to assemble, and can be reused multiple times. Aluminum formwork is also designed to create walls, floors, and roofs in one go.

Lightweight and Easy to Handle

Plastic formwork is considerably lighter than traditional materials like steel or wood. This ease of handling reduces transportation costs and manual effort on construction sites. With less arduous lifting and moving tasks, workers experience fewer physical strains and associated injuries.

Reusable and Cost-Effective

Plastic formwork can be used multiple times before it needs to be replaced. Each reuse saves money on materials compared to single-use formwork. Projects benefit from reduced overall formwork costs without sacrificing structural quality. While initial plastic formwork prices may seem higher, reusability allows funds to be redirected to other project needs. This formwork pays for itself over time.

Durability and Weather Resistance

Formed from high-density polyethylene or polypropylene, these frameworks resist impact, deformation, and deterioration. They withstand extreme heat, cold, wetness, and UV rays without warping or weakening. As a result, construction timelines experience fewer interruptions due to weather. Quality concrete walls are poured regardless of external climate conditions.

Speed and Efficiency in Construction

The light weight and ease of handling plastic formwork significantly reduce labor time and effort. Workers complete tasks faster, leading to quicker project milestones. This formwork requires no additional tools for assembly and disassembly. Its straightforward fitting boosts overall workflow efficiency on-site.

High-Quality Concrete Finish

Plastic formwork features a smooth interior surface that imparts a fine texture to poured concrete. This eliminates the need for additional surface treatments later. The material's non-stick properties allow easy concrete removal without damaging the form or the cured product. This results in intact, blemish-free concrete structures.

Versatility in Design and Application

Formwork can be adapted to create walls, foundations, columns, slabs, and more. It accommodates diverse project designs, from residential homes to high-rises and bridges. Plastic formwork allows flexible configuration into straight, curved, and angular shapes. It meets project requirements for precise dimensions and complex outlines.

Sustainability and Environmental Considerations

Many plastics used are recycled or can be recycled after their formwork life ends. This reduces waste and conserves resources. Reduced material consumption over multiple uses of plastic formwork lessens the environmental impact. Projects practice sustainability by utilizing these reusable frameworks. Faster construction times mean fewer onsite emissions from machinery and workers. Overall project timelines shrink as plastic formwork boosts efficiency.

The use of plastic formwork in construction projects is widespread due to its numerous advantages over traditional formwork systems. Here are some common usage scenarios:

Reinforced Concrete Structures

Plastic formwork is widely used in constructing reinforced concrete structures such as:

Retaining walls

Bridges

Parking structures

Basements

Foundations and footings

Plastic formwork is suitable for creating walls, columns, beams, and slabs in these structures. It is easily customizable to different shapes and sizes.

Residential Buildings

Plastic formwork is commonly used in constructing residential buildings, including:

Single-family homes

Multi-family dwellings

Condominiums

Plastic formwork is particularly beneficial in building projects where speed and cost-effectiveness are essential. Its ease of assembly and disassembly, light weight, and reusability contribute to reduced labor and material costs.

Commercial and Industrial Structures

Plastic formwork is used to construct commercial and industrial structures, including:

Office buildings

Warehouses

Factories and plants

Retail spaces and shopping centers

Hospitality and leisure facilities (hotels, resorts, stadiums)

Educational and institutional buildings (schools, universities, government facilities)

Healthcare facilities (hospitals, clinics, medical centers)

Plastic formwork allows for the construction of large open spaces, high ceilings, and intricate architectural features in these structures.

When choosing plastic formwork plywood, there are several factors to consider. Below are some of them:

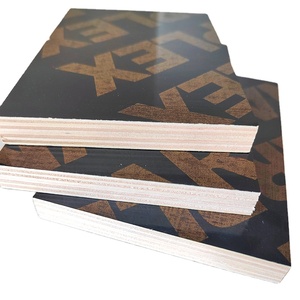

Quality of the Plywood

It is important to check the quality of formwork plywood. High-quality plywood should be constructed using durable plastic materials. It should also be well-reinforced with high-quality steel. This enhances its structural integrity. It ensures the plywood can withstand extreme pressure without collapsing.

Evaluate the Surface Finish

The surface finish of the plastic formwork plywood affects the quality of the concrete cast. Therefore, choose formwork plywood with a smooth and flat plastic surface. This ensures the concrete cast will have a uniform texture. It also reduces the concrete cast's curing time.

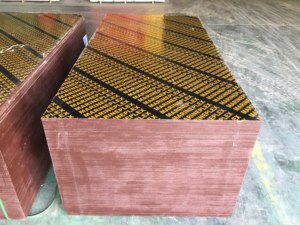

Assess the Thickness and Load-Bearing Capacity

The thickness of the plastic plywood formwork affects its load-bearing capacity. When choosing the plastic formwork plywood, assess the load pressure of the concrete project. Choose the formwork plywood with the appropriate thickness. Good thickness offers excellent load-bearing capacity. Meeting the needs of the concrete construction project.

Check for Reusability

One of the best features of plastic formwork is reusability. Therefore, the ideal plastic formwork plywood should be reusable. Check the number of times the plastic formwork can be reused. This helps to maximize the return on investment.

Compatibility with Project Requirements

Consider choosing plastic formwork plywood compatible with the requirements of the concrete construction project. This includes the concrete mix design, casting shape, and environmental conditions. Proper compatibility optimizes the performance of the concrete project.

Availability and Cost

Availability and cost are major factors to consider when choosing plastic formwork plywood. Before anything else, evaluate the budget and determine the maximum amount that can be spent on purchasing plastic formwork plywood. This prevents overspending. More importantly, consider the availability of the formwork plywood. Choose a type of formwork that is readily available in the market. This ensures timely delivery and maximizes the project's completion time.

Q1. What is the lifespan of plastic formwork?

A1. Plastic formwork can be reused up to 150 times, depending on the quality of the plastic used to make it. Its lifespan is longer than that of conventional formwork.

Q2. What are the types of formwork in construction?

A2. There are three types: traditional formwork, reusable formwork, and permanent formwork. Traditional formwork uses wooden beams and plywood. Re-usable formwork is made of steel, aluminum, and plastic. The steel and aluminum formwork are suitable for high-rise buildings, while plastic formwork is ideal for small to medium construction projects.

Q3. What is the purpose of formwork?

A3. Formwork creates a temporary structure that holds concrete in place until the concrete is cured and hardened. The formwork determines the shape, size, and finish of the concrete structure.

Q4. What are the challenges of using formwork?

A4. Some challenges include increased labor costs, poor-quality materials, and inaccurate measurements. Other challenges include weather conditions, delays in construction, and damage to the formwork.

Q5. How much does plastic formwork weigh?

A5. Plastic formwork panels are lightweight, with an average weight of 9.5 kg per square meter. Their lightweight nature makes them easy to handle and transport.