Introduction to Plastic 3D Printing Services

Plastic 3D printing services utilize advanced technology to produce intricate and precise components using various types of plastic materials. These services cater to a wide array of industries, enabling businesses to save time and costs while ensuring high-quality production. With the evolution of additive manufacturing, companies can now easily create prototypes, custom parts, and even end-use products tailored to their specific needs. Whether you require rapid prototyping to validate design concepts or require low-volume production runs, plastic 3D printing offers a versatile and efficient solution.

Types of Plastic 3D Printing Services

Plastic 3D printing services can be categorized into several distinct processes, each offering unique benefits and applications:

- Fused Deposition Modeling (FDM): This popular method extrudes melted plastic filament through a nozzle to build parts layer by layer. It is often used for prototyping and production due to its cost-effectiveness.

- Stereolithography (SLA): SLA employs a laser to cure liquid resin into solid plastic. It is renowned for producing highly detailed and smooth-surfaced parts, making it ideal for applications needing intricate designs.

- Selectively Laser Sintering (SLS): SLS uses a laser to fuse plastic powder into solid structures, producing durable components that are suitable for functional testing and end-use applications.

- Multi Jet Fusion (MJF): This method utilizes multiple jets to apply detailing agents and heat, rapidly building durable parts. Its speed and versatility make it great for production and prototyping.

Applications of Plastic 3D Printing Services

The versatility of plastic 3D printing services makes them applicable across various industries, including:

- Aerospace: Lightweight components are essential for fuel efficiency, which 3D printing can create with intricate designs.

- Automotive: Rapid prototyping allows for testing of parts, reducing lead times and development costs.

- Healthcare: Custom prosthetics, dental models, and surgical guides are created for top-tier patient care and medical innovation.

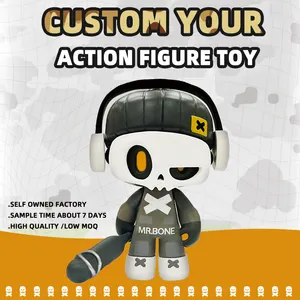

- Consumer Goods: Tailored designs for products like footwear, toys, and gadgets can be produced quickly and at lower costs.

Advantages of Using Plastic 3D Printing Services

Utilizing plastic 3D printing services presents a host of advantages that significantly enhance production capabilities:

- Cost Efficiency: Reduced material waste and lower production costs compared to traditional manufacturing methods.

- Customization: Ability to create custom designs and prototypes that meet specific client requirements, perfect for niche markets.

- Speed: Rapid turnaround times from design to production make it easier to adapt quickly to market changes.

- Complex Geometries: Capability to produce complicated shapes and features that would be impossible or expensive with conventional techniques.

- Material Variety: Access to a wide range of plastics, including flexible, durable, and heat-resistant options, to meet diverse applications.