All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(1202 products available)

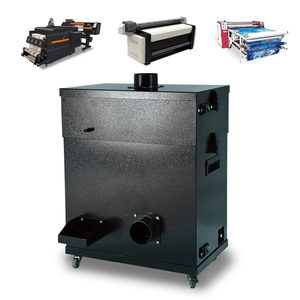

A plasmac cutting fume filter is a device designed to purify and safeguard the environment from harmful plasma cutting smoke and fume emissions. There are various types of plasma cutting fume filters, which can be classified according to their design, work principle, purpose, and packaging.

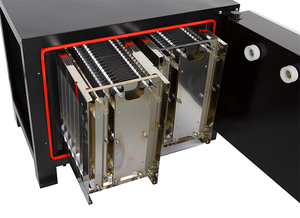

The crucial component of a plasma cutting dust extractor is the filter itself. Plasma cutting fume filters can be classified into two categories according to how they are cleaned: automatic or manual cleaning. Manual cleaning entails operating levers or buttons to start the cleaning process, whereas automatic cleaning entails a pre-programmed, timed pulse jet filter. The plasma cutting fume extractors' fan motors are another option. They may be of three types: side channel blowers, centrifugal motors, and inline or tube motors. For high vacuum applications, side channel blower motors are employed to produce high suction at a low power rating. For general-purpose use, disc-shaped centrifugal fan motors are suited. Designed to be slim and compact, inline or tube motors are installed in tight spaces. The filter units themselves come with carbon filter units, HEPA filter units, or both. Gas filters that employ the adsorption concept to remove gaseous contaminants from the air are carbon filter units. Particulate matter is captured by HEPA (High-Efficiency Particulate Air) filter units. Depending on their capacity, some dust extractors have a storage bag or container for the dust waste.

Plasma cutting fume extractor maintenance is crucial to ensuring optimal performance and protecting the health of users. The filters must be cleaned on a weekly or monthly basis, depending upon the type of extractor and frequency of its usage. Used in plasma cutting fume extractors, HEPA filters are to be replaced every 3 to 5 years generally. The carbon filters, their longevity depending on the type of extractor and material being extracted, may need early replacement if they begin to smell after being cleaned. Parts like the fan and the motor must be checked individually. The fume extractor's external casing should be washed every 1 to 2 months. A deep cleaning of the device can be done every 6 months. Regular maintenance of plasma cutting fume extractor not only helps its better functioning but also increases its longevity.

Since the fume extraction system for welding and plasma cutting is designed to collect and eliminate fumes resulting from welding, cutting, or related activities, it proves useful across many industries.

When selecting a plasma cutting fume extractor, the key is to choose a machine that provides proper filtration for all present contaminants, including the ones released during plasma cutting.

Consider the filter cartridges:

The cutting fumes contain a considerable amount of welding smoke. Hence, the extractor must have filters capable of handling this flux. Look for Extractor Filters with cartridges that have the following attributes:

Therefore, both filters work together to ensure air cleaning and prolong the extractor's functionality.

Check the air flow:

In this context, air flow refers to the volume of air extracted by the extractor unit and is usually measured in cubic meters per hour (m3/h). The extractor's primary purpose is to remove cutting fumes from the work area, ensuring operators' safety. To achieve this goal, the extractor must maintain a sufficient air flow rate. A fast air flow rate ensures that fumes are captured from the source and properly filtered before the cleaned air is returned to the environment.

Determining the required air flow for a work task depends on a few factors, such as the number of cutting tasks performed in a given period and the frequency with which those tasks are conducted. Using cutting equipment with suction nozzles can also affect the extraction required. Conducting an assessment based on these parameters will enable a more accurate determination of the air flow needed to handle specific cutting tasks efficiently.

Assess system noise:

Certain extractor units can produce high levels of noise due to their powerful motors. Prolonged exposure to this loud noise can have harmful impacts on users' health. Therefore, while selecting a plasma cutting extractor, consider the unit's noise level. Choose a model that has a noise level measured in decibels (dB), which is within a safe range for users.

Moreover, selecting a model with a relatively low noise level enhances users' comfort. This decision leads to more productivity on the cutting worktasks.

Q1: What are the plasma cutting filter cartridges composed of?

A1: Filter cartridges for plasma cutting are typically composed of dust collecting bags manufactured from fabric. The fabric is a combination of polyester and other protective membranes or coatings, resulting in a material both robust enough to filtering hazardous particles and capable of withstanding high temperatures.

Q2: Does the filter in a plasma cutter fume extractor need to be replaced?

A2: Ideally, the filter in a plasma cutter fume extractor will not need to be replaced frequently if it is properly maintained. The lifespan of the filter depends upon the handling of the plasma cutter and the type and amount of material being cut. Regular cleaning of the filter, as mentioned before, is important to its continued use, but eventually, all filters will become too saturated with particles to be effective and will need to be replaced.

Q3: How do plasma cutting fume filters work?

A3: The plasma cutting fume filter works by physically trapping the particles within its fabric. Micro-fibers in the filter bags capture and hold particulates while allowing clean air, or filtered air, to pass through and be released back into the atmosphere or redirected into the workspace via ducting.

Q4: How often should the fume extractor filter be cleaned?

A4: The frequency with which to clean the extractor filter is dependent on the plasma cutter in use, the material being cut, and the amount of plasma cutting carried out. Filters should be inspected regularly, and cleaning should occur whenever there is a build-up of dust or debris.

Q5: What are some maintenance tips for plasma cutting fume filters?

A5: Maintenance tips include the following: always following the manufacturer's instructions to ensure proper cleaning and filter handling; using the right extractor for the plasma cutter being used; ensuring the correct filtering cartridge is selected; keeping the filter dry whenever the extractor is not in use; and inspecting the filter regularly for any damage or signs of wear.