Introduction to Pipeline Welding Helmets

The pipeline welding helmet is an essential piece of personal protective equipment (PPE) designed specifically for professionals engaged in pipeline welding tasks. These helmets offer a combination of safety, functionality, and enhanced visibility to ensure that welders can perform their jobs effectively while protecting themselves from the various hazards inherent in the welding process. With advancements in technology and materials, modern welding helmets have become indispensable tools in the welding industry.

Types of Pipeline Welding Helmets

Pipeline welding helmets come in various types, each tailored to meet the specific requirements of different welding methods and environments. Here’s a breakdown of the most common types:

- Auto-Darkening Helmets: These helmets feature sensors that automatically adjust the lens shade in response to the brightness of the welding arc, allowing for seamless transitions between working phases.

- Fixed Shade Helmets: These helmets have a pre-fixed lens shade and are generally less expensive, making them suitable for hobbyists or those who don’t require dynamic adjustments.

- Full-Face Welding Helmets: Offering complete head coverage, these helmets provide additional protection against flying sparks, slag, and other debris.

- Lightweight Helmets: Designed for comfort during extended use, lightweight helmets minimize fatigue and enhance the user’s experience during long welding sessions.

Applications of Pipeline Welding Helmets

The pipeline welding helmet is optimized for a variety of applications, making it versatile for different fields. Below are some primary applications:

- Oil and Gas Industry: Pipeline workers often face intense conditions, and welding helmets are crucial in protecting them from UV radiation and thermal burns.

- Construction Projects: During the construction and maintenance of various infrastructure, welding helmets keep workers safe while performing critical tasks.

- Shipbuilding: In shipyards, where welding is a daily task, these helmets shield workers from hazardous conditions including potential electrical shocks.

- Manufacturing Plants: For manufacturers specializing in metal works, pipeline welding helmets are indispensable in ensuring the safety of staff while maintaining productivity.

Features and Advantages of Pipeline Welding Helmets

When selecting a pipeline welding helmet, it is vital to understand its features and advantages, which greatly enhance user experience and safety:

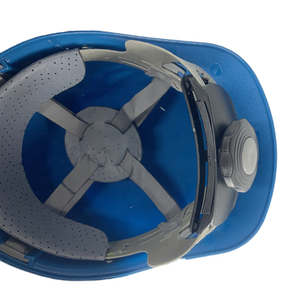

- Comfort Fit: Ergonomically designed helmets come with adjustable headgear that provides a secure fit, promoting comfort even during prolonged use.

- High-Impact Resistant Materials: Made from durable materials like polycarbonate and fiberglass, these helmets offer robust protection against collisions and scratches.

- Clear Visibility: Many models feature wide viewing lenses to provide an expansive field of vision, allowing welders to work more efficiently without compromising safety.

- Integrated Respiratory Systems: Some advanced models include built-in ventilation systems, ensuring a steady flow of fresh air to reduce discomfort while welders breathe.

- Durability and Resistance: Pipeline welding helmets are designed to withstand harsh environments, and resistance to heat, sparks, and chemicals further extends their service life.