All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(312 products available)

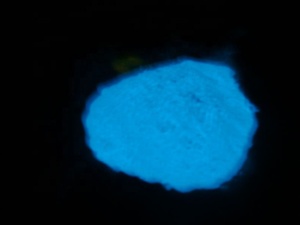

Photoinitiators are vital substances for UV curing. UV curing is a process where a liquid polymer transforms into a solid form. This transformation occurs through exposure to ultraviolet light. Curing is common in the manufacturing of coatings, inks, and adhesives. When suppliers offer UV cured products, they aim to boost product sales to retailers. Retailers then sell the products to consumers who desire highly durable goods.

Photoinitiators are vital for the success of the UV curing process. When UV light hits them, they produce radicals or ions. The radicals act as catalysts to start the polymerization process. There are two main categories of photoinitiators:

As shown in the name, free radical photoinitiators generate free radicals upon UV light exposure. The radicals then react with liquid monomers in UV curing substances. This reaction causes the monomers to bond and form a solid polymer structure.

Common free radical photoinitiators include:

These radicals are extremely reactive. Therefore, they efficiently initiate polymerization in a wide range of UV-curable formulations. The radicals also add directly to unsaturated bonds in monomers. This ability is called 'chain initiation'. Free radicals then generate longer polymer chains that are more effective at cross-linking.

The free radicals also help bonded monomers to link up and form stable cross-linked polymers. These radicals also improve the physical properties of the final product. Some properties include enhanced adhesion, scratch resistance, and chemical resistance.

Cationic photoinitiators, in contrast, generate cations (positively charged ions) when exposed to UV light. They are less common than free radicals but have specialized uses. For example, they are useful for UV curing of coatings in:

Cationic photoinitiators are ideal for these areas since they cure most effectively in anoxic conditions. Manufacturers prefer to use them in oxygen-sensitive applications. Oxygen inhibits free radical polymerization.

Common cationic photoinitiators include:

Cationic UV curable formulations also offer advantages like improved adhesion to challenging substrates, decreased yellowing, and enhanced resistance to water and acids. Cationic photoinitiators can also be combined with free radical photoinitiators.

The hybrid approach takes advantage of the inherent properties of radicals and cations. Co-initiators allow the simultaneous promotion of different types of polymerization. This flexibility enables formulators to fine-tune the performance characteristics of UV-cured products to specific application requirements.

Photoinitiators are an essential component of various industrial applications. They are integral to the formulation of UV-curable inks, coatings, and adhesives in numerous sectors. Here are the prominent applications:

Photoinitiators are vital in packaging printing. Printers use them to produce vibrant colors that cling to diverse surfaces. Strong adhesion enables better quality and more visually appealing printed packages. Photoinitiators in inks also improve print durability. Thus, the prints are more resistant to scratching and other physical damage. Increased durability also expands the packaging options available to printers to serve downstream manufacturers.

Photoinitiators also improve coatings for industrial applications. They help them become more effective by making them with faster curing times and superior performance. Photoinitiators enable coatings to form strong bonds and build protective layers on substrates. Such a feature leads to improved protection for valuable equipment and machinery. Strong bonds and protective layers also benefit corrosion protection and enhanced chemical resistance.

In wood finishing, photoinitiators help create aesthetically pleasing and long-lasting products. They do this by allowing faster and more efficient finishing processes. Thus, furniture manufacturers can deliver products more quickly without compromising quality. Manufacturing speed without quality impact meets the increasing customer demand for durable wood products. Photoinitiators also play a vital role in the aesthetics and performance of wood products.

Electronics producers also leverage photoinitiators in their production. These initiators lead to better performance and reliability of devices by enabling robust circuit board coatings and adhesive applications. Improved battery insulation is one benefit of initiators in circuits boars. Moreover, integrated devices can feature finer designs with enhanced insulation and protection, promoting innovation in electronics.

In the adhesive industry, photoinitiators enable quick bonding processes. Hence, manufacturers can achieve instant hold with greater effectiveness in their products. Stronger bonds lead to increased reliability of glued products. This enhancement benefits downstream producers who assemble products and depend on the consistent performance of their adhesive applications.

There is an increasing use of photoinitiators in 3D printing. They enable precise printing and rapid prototyping. Precise printing means businesses can iterate more quickly. Quick iteration promotes innovation and improved product development in a shorter time frame.

Ultimately, the integration of photoinitiators in various applications significantly impacts quality, durability, and efficiency. The resulting improvements benefit many industries, leading to increased customer satisfaction and business success.

The key features of photoinitiators for UV curing are:

The usage of photoinitiators for UV curing varies based on the type of photoinitiator. Free radical photoinitiators usually have lower activation energy. So, they start the polymerization process at room temperature.

Conversely, cationic photoinitiators need higher activation energy. They have more complex procedures during the application. Here's how to apply them:

Free radical photoinitiators can be added directly to the formulation. They mix with other components without special requirements. But cationic photoinitiators need a more complex mixing procedure. They require acidic promoters to dissolve them. Then, they mix with the formulation baseline before adding other components. Note that this step is essential. It ensures the photoinitiators are fully activated.

Once mixed, apply the formulation to the target surface using preferred methods. Some methods include brushing, spraying, or pouring. Ensure a uniform layer that promotes consistent curing.

To achieve optimal performance, UV-light exposure must adequately activate the photoinitiator. If the exposure is insufficient, polymers form slowly or not at all. Also, poor bonding might occur. Conversely, excessive exposure leads to over-curing. Using the correct dosage of photoinitiator avoids insufficient or excessive exposure.

Here are some common aspects to consider:

Further, using photoinitiators with low viscosity improves mixing and application. They ensure even distribution across surfaces. But, care must be taken not to use highly viscous photoinitiators. They lead to uneven polymerization. This creates weak spots within the cured material.

UV curing products do not have direct maintenance requirements. Instead, maintenance occurs during the production stage. For example, monitoring and controlling photoinitiators and UV exposure ensures optimal performance and prevents product defects. On the other hand, the repair or replacement of was damaged or defective products usually happens through warranty policies that manufacturers establish. The policies are based on industry standards and agreements with their customers.

Some major quality factors play an important role in photoinitiators for UV curing. These factors mainly influence their performance and reliability. So, here are the key quality considerations to keep in mind:

In this case, high-quality photoinitiators must have a high level of purity. They should contain little to no impurities or contaminants. Impurities can cause inconsistency during the UV curing process. They result in poor adhesion, weaker bonds, and lower product durability. Hence, manufacturers must choose initiators with documented compositions to ensure consistency.

Here, the reactivity of photoinitiators should match the requirements of specific applications. If the reactivity is low, it leads to slow curing rates. Further, low curing rates cause incomplete polymerization.

On the flip side, excessive reactivity results in a rapid curing process. Rapid curing makes it challenging to achieve uniform results. The outcome, in this case, is products with inadequate strength and defective appearance. Therefore, selecting photoinitiators with appropriate reactivity levels for different applications is required.

This compatibility is mainly with other formulation components. Photoinitiators should easily mix with the resins, solvents, and additives in UV-cured formulations. Poor compatibility leads to separation or precipitation. This issue impairs the initiation process, resulting in subpar products. To prevent this problems, manufacturers must assess the compatibility of selected photoinitiators with available formulation components.

Safety is a major concern since photoinitiators encounter direct exposure to UV light. They may produce hazardous fumes that threaten the safety of the working environment. Below are the safety considerations to keep in mind:

When exposed to UV light, some photoinitiators decompose and emit hazardous fumes. The fumes consist of toxic substances like carbon monoxide, nitrogen oxides, and volatile organic compounds (VOCs). These gases negatively impact employee health and contribute to atmospheric pollution. If there are no proper safety measures, such as effective ventilation systems, employees may suffer respiratory issues. Also, the overall risk of fire and explosion increases.

Manufacturers usually rely on various methods to minimize exposure and associated risks. They use personal protective equipment (PPE) like gloves and goggles as protective measures. PPE protects employees from direct contact and potential skin or eye irritations. Also, implementing proper labeling and safety data sheets (SDS) improves PPE effectiveness. It provides important information on risks, handling, and emergencies.

Disposing of photoinitiators without proper measures results in hazardous waste management. The initiators' hazardous nature means that standard disposal practices are insufficient. They integrate into landfills and further endanger environmental pollution. Conversely, incineration releases toxic emissions.

The best way to manage photoinitiators waste is to use designated hazardous waste containers. The containers finally transport to licensed facilities for proper treatment and disposal. This practice ensures that waste is either recycled or treated to minimize its harmful effects.

Free radical photoinitiators usually suit general UV curing tasks. In those tasks, manufacturers polymerize coatings, inks, adhesives, and sealants. Conversely, cationic photoinitiators are better for specialized applications. They are ideal for polymerization that involves highly reactive monomers. They are also suitable for coating electronics.

Here, the type of photoinitiator depends on the formulation. In cationic formulations, photoinitiators are usually aryl sulfonic acids, ary sulfonate esters, chlorosulfonates, and diazonium salts. Conversely, alkyl ketones, hydroxyalkyl aryl ketones, and thioxanthones are for free radical formulations. The choice of initiator for the formulation influences the resulting product's appearance and physical properties. Thus, it is essential to consider the photoinitiator type when for product quality.

The material of the surface or substrate also determines the type of photoinitiator. For example, bonding photoinitiators are ideal for difficult surfaces like plastic and metal. They promote strong adhesion and ensure durable finishes. On the other hand, transparent varieties are suitable for clear coatings. They prevent noticeable changes in appearance. So, manufacturers should consider the substrate surfaces to ensure they select photoinitiators that maintain consistency across diverse surfaces.

Environmental factors like temperature and humidity affect photoinitiators' performance. For instance, elevated temperatures degrade some initiators. Meanwhile, excessive humidity levels lead to premature photoinitiator activation. Conversely, extremely dry conditions cause their further degradation. Cationic photoinitiators are more sensitive to these factors than free radical ones. They are less tolerant to high temperatures and prolonged exposure.

Manufacturers must consider the regulatory requirements in their region. Regions create regulations based on the environmental impact and occupational safety concerns. These rules usually involve limitations on VOC emissions and toxicity levels. Therefore, purchasing managers must live up to these regulations by selecting photoinitiators that comply with essential industry standards.

Market players are emphasizing creating bio-based photoinitiators. The initiators come from renewable resources like natural oils and plant extracts. This development reduces the carbon footprint of UV-cured products while maintaining effective performance. Additionally, there is a growing interest in discovering photoinitiators with synergistic effects. The discovery enables using lower concentrations while enhancing polymerization efficiency. This increase benefits manufacturers by lowering costs and reducing the environmental impact.

One major factor is the formulation manufacturers use. There are cationic photoinitiators that work best for monomers with a high electron affinity. Conversely, free radical photoinitiators are ideal for standard formulations. The substrate surface also determines the choice. For example, potent bonding photoinitiators are suitable for challenging surfaces. At the same time, transparent ones are ideal for clear coatings. Environmental conditions like humidity and intense heat affect the performance of photoinitiators.

They implement various mitigation measures to reduce exposure and associated risks. They use PPE like gloves and goggles to prevent direct contact with photoinitiators. They also incorporate ventilation systems to capture and dilute hazardous emissions. These systems promote safer working environments. Moreover, they follow the safety data sheet's guidelines and recommendations.

They must prioritize sure the stability and reactivity of the photoinitiators. They significantly impact UV curing effectiveness. Therefore, buyers should acquire photoinitiators onsite in temperature-regulated spaces. Doing so maintains their potency. Additionally, purchase photoinitiators with special bonding capabilities to suit various substrates. This feature ensures strong adhesion across multiple surfaces.