All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(3500 products available)

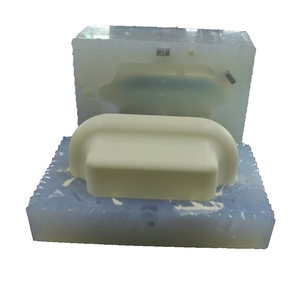

A phenolic resin mould is a mould made from phenolic resin, a type of synthetic polymer often used in creating moulds. These moulds can be employed in various applications, such as producing components for the automotive, aerospace, and consumer goods industries. Below are some common types of phenolic resin moulds.

Compression Moulds

These moulds are made by compressing a heated material between two halves of a mould. They are durable, have good chemical resistance and can be used to make complex parts.

Injection Moulds

These moulds inject the resin into the mould cavity to create a part. Injection moulds are precise, have a fast production rate and can make complex shapes.

Transfer Moulds

Transfer moulding moves the material into the mould cavity using heat and pressure. These moulds are versatile, have good detail and can make complex parts.

Roll Moulds

Roll moulds create a continuous product by rolling the mould in the material. These moulds are suitable for making pipes, tubes and films.

Extrusion Moulds

These moulds push the material through a die to create a continuous shape. They are suitable for making rods, sheets and profiles.

Vacuum Forming Moulds

These moulds create parts by sucking the material into a mould using a vacuum. They are suitable for making packaging and food containers.

Blow Moulds

These moulds create hollow parts by blowing air into a material in a mould. They are suitable for making bottles and jars.

Cold Moulds

Cold moulds use ambient temperature to cure the resin. They are easy to use, have low energy consumption and are suitable for making small parts.

Injection Moulds

These moulds inject the material into the mould cavity using a piston. They are precise, have a fast production rate and are suitable for making complex parts.

High-definition Moulds:

These have very fine details that can retain the roughness or texture of the original species. Photopolymer resins are used to create these moulds.

Functional Moulds:

These are moulds that do not have a high definition but serve the purpose of casting. They are made from durable materials like silicone or urethane rubber.

Production Moulds:

These are large-scale functional moulds that can produce many identical pieces. They are used in industries where mass production is required, and they usually employ injection moulding or 3D printing techniques.

Artistic Moulds:

These are unique, one-of-a-kind pieces designed by artists to create specific art pieces. They can be high-definition or production moulds based on the artist's intent and use materials like silicone, urethane, or plastics such as photopolymer or epoxy resins to create novel and rare objects.

Moulds For Specific Applications:

These are specialised for certain fields, such as dental, jewelry, or lab sciences. They are designed for accuracy and detail and use materials like silicone, urethane rubber, or epoxy resins to create specific tools and objects used in those fields.

Phenolic resins have a wide range of applications. These applications require moulds that can withstand extreme conditions, produce intricate designs, and ensure high-quality finished products. The scenarios where phenolic resin moulds are used include:

Phenolic resin moulds are important in many industries. They are used where high heat resistance, chemical resistance, and precise details are needed. These moulds enable the production of complex parts and components. They have a durable design, reduce the need for frequent replacement, and lower the cost of ownership in the long run.

Purpose and Application:

Determine the specific purpose of the mould and the intended application. Consider factors such as the type of products being moulded, production volume, required surface finish, and the materials being used. For example, if the mould will be used for high-temperature applications, selecting a phenolic resin with heat resistance would be crucial.

Material Selection:

Select the appropriate phenolic resin material for the mould based on the application requirements. Phenolic resins come in various grades, including novolac, resol, and epoxy-modified formulations. Each grade has unique properties such as hardness, chemical resistance, and moisture absorption. Choosing the right material ensures the mould can withstand the expected conditions during production.

Design Considerations:

Ensure that the mould design facilitates efficient production and quality casting or forming. Incorporate features like proper venting to allow gas escape, uniform wall thickness to prevent weak points, and interlocking patterns for easy demoulding. Consider the material flow characteristics and shrinkage of the casting material to optimise the mould design for accurate reproduction.

Durability and Maintenance:

Phenolic resin moulds should be durable enough to withstand repeated use and the associated wear and tear. Evaluate the mould's maintenance requirements, such as cleaning procedures and the need for periodic inspections or repairs. Moulds that are easy to maintain and have extended service life offer better long-term value and reduce downtime in production processes.

Cost and Budget:

Consider the mould's cost and the overall budget. Evaluate the initial investment and the potential costs of maintenance or replacement. Balancing the mould's quality and affordability is essential to ensure it meets the production requirements without exceeding the budget.

Compliance and Standards:

Ensure that the phenolic resin mould complies with relevant industry standards and regulations. Compliance ensures safety, performance, and compatibility with other components in the production process. Stay updated with the latest standards to ensure the mould meets quality assurance requirements.

Q1: What are the benefits of phenolic resin moulds?

A1: Phenolic resin moulds are durable, heat-resistant, and have good chemical resistance. They provide a smooth finish and can be produced in a variety of shapes, making them ideal for many industrial applications.

Q2: How can phenolic resin moulds be stored?

A2: Store phenolic resin moulds in a cool, dry place away from direct sunlight and extreme temperatures to prolong their life.

Q3: What industries use phenolic resin moulds?

A3: These moulds are used in sectors such as automotive, aerospace, construction, and manufacturing, where there is a need for reliable and high-performance moulds.

Q4: Can phenolic resin moulds be recycled?

A4: The recyclability of phenolic resin moulds depends on the specific formulation and the recycling processes available. It is essential to consult relevant recycling guidelines for information on the recyclability of phenolic resin moulds.

Q5: What factors should be considered when selecting a phenolic resin mould?

A5: Consider factors such as the desired properties of the end product, the type of material being moulded, the production process, and the performance requirements when selecting a phenolic resin mould.