(3500 products available)

There are several types of PCB prototype machines for producing small-scale PCB prototypes. The specific type and model used will depend on the size and complexity of the circuit board being manufactured.

Specifications for PCB prototypes vary depending on the type of machine being used. Below are some general specifications for different PCB machines:

PCB size:

PCB prototype machines have different sizes for maximum prototype dimensions. For example, some machines can handle PCB sizes of about 610mmx 457mm. They can also process flexible circuits with a maximum width of about 380mm.

Layer capability:

Some PCB machines have the ability to prototype multilayer boards, including complex stackups with up to 32 layers or more. These multilayer boards often include high-density interconnects, blind and buried vias, and other advanced features.

Drilling capabilities:

PCB machines come with various drilling capacities ranging from precision micro-drilling to standard via drilling. Some machines even include laser drilling for creating precise holes in PCBs. The drilling speed of the machine can also vary depending on the model.

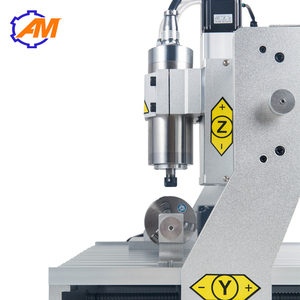

Routing:

Routing capabilities allow machines to cut out PCB panels and separate individual boards. This is typically done using a high-speed spindle to mill precise shapes and contour PCBs. Some machines can even perform as much as 5 routing passes.

Finishing options:

When it comes to the finishing options, the machines may vary from one model to another. Some may include solder mask application, silkscreen printing, and surface finish deposition such as ENIG or HASL.

Imaging technology:

PCB prototype machines use different types of imaging technologies, such as UV LED or laser imaging. These methods transfer the circuit pattern onto the photosensitive materials used in the PCB manufacturing process.

Manufacturing speed:

Different types of machines have different speeds when it comes to PCB manufacturing. For instance, a rapid PCB prototype machine can produce a board in as little as 24 hours. However, this machine is more expensive than others that take months to finish.

For PCB prototype machines to remain efficient and function well, they must be maintained regularly. Below is some maintenance advice for different types of PCB machines:

Regular cleaning:

The machine has to be cleaned regularly to remove any debris or dust that has settled on it. All surfaces, including the drilling and milling bits, vacuum nozzles, and chuck, need to be cleaned. A lint-free cloth and little isopropyl alcohol can be used to clean all parts of the machine.

Lubricating moving parts:

The moving parts of the prototype machine should be periodically lubricated to ensure their smooth operation. This includes guiding rails, lead screws, and linear bearings. When Lubricating, use only the recommended lubricant by the manufacturer.

Calibration:

Some prototype machines require calibration to ensure their accuracy. This is especially important for other types of machines that drill precision holes. During calibration, operators should follow the manufacturer's instructions and use the specified calibration standards.

Dust and moisture control:

Dust and moisture have a huge impact on the efficiency and lifespan of a PCB machine. Therefore, users should work in an environment where there is minimal dust and moisture. As a result, they will be protecting the sensitive components of the machine.

The introduction of the pcb prototype machine has changed the application scenarios for PCBs. Now, machines can produce PCBs accurately, saving time and costs. Here are some scenarios where PCB prototype machines are helpful:

Startups and Innovators

New companies and independent innovators need small quantities of PCBs at first. The PCB prototype machine is cheap and gives them a fast way to work on their ideas. So, new businesses can use the machine to build their first products quickly and at a low cost.

Design Changes and Testing

Companies usually change their designs after user testing. With the prototype machine, they can build new versions of the PCB quickly instead of waiting a long time. Faster design changes and further testing help product development speed up.

Educational Purposes

In teaching situations, prototype machines are good tools for hands-on learning. Students can create their PCB designs, putting them into practice. This experience provides deeper understanding of circuit design, fabrication methods, and troubleshooting techniques. Moreover, it can instill valuable skills related to engineering disciplines.

Medical Device Development

As an illustration of the preceding scenario, consider the field of medical device development. In this particular realm, it becomes imperative to conduct rapid prototyping in order to facilitate timely iterations and refinements ofPCB prototypes machines. Such agility is essential for enhancing product performance, optimizing functionality, and ensuring regulatory compliance.

Art and Design Projects

In the circuit design and artistic creativity industry, the fusion of art and technology gives rise to unique and captivating products. Artists and designers are empowered by the PCB prototype machine to bring their innovative ideas to life in the form of distinct electronic devices. These creations may showcase exquisite functionality while incorporating unconventional aesthetic elements that defy conventional norms.

Several factors should be considered when choosing a PCB fabrication machine for prototypes.

Q1: What is the future trend of PCB prototype machines?

A1: PCB prototype machines are developing towards intelligent and automated production. Intelligent management systems can realize remote monitoring and control of machines, thereby facilitating production scheduling and quality management. In addition, the automation of machines will be further improved, which will have higher degree automation and simplify manual intervention requirements.

Q2: What is the impact of PCB prototype machines on the environment?

A2: Eco-friendly PCB prototype machines can reduce waste and energy consumption. They can produce more efficient PCBs, which will reduce the demand for raw materials. In addition, some machines adopt recyclable materials and modular designs, which promote the recyclable and sustainability of equipment.

Q3: What are the challenges faced by the PCB prototype machine industry?

A3: The machine industry faces some challenges, such as the rapid development of technology that requires constant innovation and upgrade of machines. Moreover, the quality requirements of prototypes are higher, which demands the precision and reliability of machines.

Q4: How do PCB prototype machines ensure the quality of products?

A4: The quality assurance of the PCB prototype machine is realized through several key links. First, selecting high-quality raw materials, such as substrate materials and coating materials, is the basis for ensuring product quality. Second, the machine is equipped with advanced processing technology, ensuring that the prototype meets the designed specifications and requirements.