All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(930 products available)

The performance of a plotter depends significantly on the type of cutting required and the thickness of the material. Thus, making the right choice is critical to ensuring efficiency in bulk operations.

Vinyl Cutters

These are widely used in making business signage, cars, and home décor. They use blades or laser technology to create accurate cuts and are best suited for cutting thin to medium paper.

Blade Cutting Plotter

These use a blade to cut designs, making them suitable for precise cuts. They work best with thin chipboard and paper.

Tangential Cutting Plotter

These are designed for thicker materials such as cardboard and plastic. The blades can tilt while cutting to ensure precise cuts on tricky materials, improving cutting quality on complex designs.

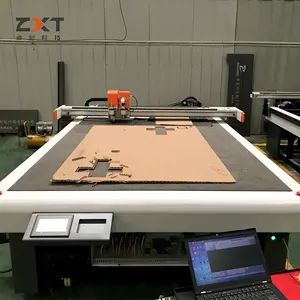

Flatbed Cutting Plotter

This is ideal for all sorts of thicker materials. It has a flat cutting table where the material can be placed. Thanks to the vacuum suction, it holds the material securely while the blade moves to cut out the desired shape. These cutters can also handle some advanced cutting tasks, such as dragging blades that need pressure to use for cutting.

Laser Cutting Plotter

It uses lasers to cut through paper. It is ideal for making intricate patterns on thin paper without ending up with rough edges. Laser cutting plotters are especially good for making crafts, such as cut-paper artwork. Unlike vinyl cutters, laser cutting doesn't require the vinyl overlay. It can also cut etch and engrave to add designs on the material surface for better texture.

The design of a paper summa cutting plotter depends on its parts.

Blades

It is an important component that determines the cut quality and the type of material that can be used. Typically, the blades are made from tungsten carbide, which is a tough and durable material that holds sharp edges for long. Blades also come in varying degrees of diameter size and angular inclination. Smaller blades are ideal for fine detail work, while bigger blades are necessary for heavy cutting work.

Cut Head

This holds the blade before burying it in the material to make cuts. The cut head then moves around the cutter according to the design transfer. Most blades are designed to automatically adjust the angle when cutting to enable better cut material precision. Such cutters are referred to as tangential or automatic blade-cutting plotters. Others will have paper summa cut plotter manual adjustments.

Material Holder

The holder will keep the material stationary while the blade, within the cut head, moves around it to make cuts. In most designs, there is a sticky layer on the holder that keeps the material firmly without sliding. The plotter comes with flatbed design-type material holders.

Motors

The motors help move the cut head and blade and rotate the blade for making cuts. High-quality plotters use stepper or servomotors, which provide precise control for better cuts. The motors are also designed to offer varying speed to cut at different speeds, dependent on the material used.

Rollers

These help pull the material through the holder for making cuts. Quality plotters have rollers with a sticky layer to hold the material tighter to prevent slipping. The roller design comes in different styles, with some having one roller and others having several. More rollers contribute to getting the material pulled quickly and smoothly compared to a single one.

Being aware of the technical specification of the plotter and the maintenance required helps to keep it in the best operational state to make it ideal for long work without breakdowns.

Size and Cutting Area

This will determine the cutting range. Those large format plotters have bigger cutting sizes. It is ideal for large projects. Small plotters handle A4 sizes. Large ones can manage A1 or even more. Larger paper summar plotters also come in higher motor power.

Cutting Force

This is the force that pushes the blade into the material. Materials such as cardstock require more cutting force than simple ones like vinyl. Plotters with adjustable cutting forces are helpful for projects that deal with many different materials.

Speed

Cutting speed is typically measured in millimeters per second. Higher speeds lead to completing the projects quickly, but often with less accuracy if not managed well. For quality cuts, it is necessary to set the speed low, especially when dealing with small detailed materials. Large projects can operate at full speed, while detailed work requires slowing time down.

The critical maintenance task focuses on keeping plots functional and cutting accurately. The following maintenance tasks help achieve smooth operation.

Blade Maintenance

This requires frequent checking to see if the blades need sharpening or replacement. Dull blades will lead to inaccurate cuts or even no cuts. The blades are often made from tungsten carbide and need to be carefully stored, or they will become dull very fast.

Rollers Maintenance

It helps maintain the rollers to ensure that the material is pulled through appropriately without slipping. Materials can also leave some sticky residue on the rollers. Clean them using a damp cloth. Avoid using harsh chemicals, as they can damage the roller material.

Lubrication

Most types of cutters require a lube to function well, particularly those with moving parts. Always refer to the manufacturer's guide to see how often it should be lubricated.

Software Updates

The plotters are often designed to run with computerized software. This is one way of creating designs and sending them to the cutter. Outdated software will lead to inaccuracies in cutting. Always check the software status and update it from time to time.

Cleaning

The cutting area should always be kept clean. Debris and residue will accumulate from the materials. This can lead to inaccurate cuts so that it should be cleaned often.

Paper summa cutting plotters are versatile tools commonly used in many fields, from simple day-to-day activities to more complex industrial uses. Here are the most common scenarios where the cutters are needed.

Personal Crafting

These are commonly used for precision crafting work. This includes card making, scrapbook embellishments, and custom invitations. Paper Cutting Plotters save time and effort in manual cutting, especially for intricate designs. Also, they ensure that all cuts are uniform and straight, which is crucial for projects that require several similar cut parts.

Commercial Printing

They are utilized in the printing business to pre-cut materials for making brochures, business cards, stickers, and posters. They help cut operational costs and tasks when creating high-volume orders with complex designs. The cutters enable quick set-ups with less labor, thus allowing businesses to focus more on other aspects of their services.

Signage Creation

They assist in crafting vinyl signs, such as decals, labels, and windows. They make signage creation more precise, improving the sign life span and visual appealing. When compared to manual cutting vinyl, plotters are more efficient in dealing with intricate and detailed cuts.

Architectural Model Making

Architects use cutters to produce quick scale paper models. Plotters help save time in making complex models. They help ensure accuracy, which is very essential in transferring architectural design to make physical models.

Educational Projects

They are commonly used in schools for teaching and learning activities. They assist in making cut-out designs for learning posters, teaching charts, and custom educational materials. They help instructors and students finish their projects quicker while ensuring precision in cut-outs, which can be tough in practical learning.

Custom Packaging

They help design unique packaging boxes, labels, and inserts for product protection and presentation. They assist in the development of fast, high-quality, and low-cost packaging solutions. The cutters also ensure accuracy and consistency, leading to increased efficiency and minimal wastage.

A1. The plotters can cut simple materials such as thin paper, cardstock, and durable materials like chipboard and vinyl. Complex ones cut thicker materials like cardboard and plastic.

A2. The primary function of printers is to apply ink or toner to paper to create images or text. On the other hand, plotters physically cut materials to make shapes, designs, or patterns. Therefore, printers are mainly used for producing pictures, while plotters for producing detailed crafts or designs involving cutting.

A3. Some blades are typically replaceable, while others are in the form of a blade cartridge that requires changing when the blade gets dull. Further, standard blades can be sharpened, while grinding blades cannot be sharpened. The blades used will also determine how long the cut will take.

A4. The cutters require basic care, such as blade replacement or sharpening, regular roller and cut head cleaning, and lubricant application. Proper maintenance of the plotter helps ensure its fine operational state while increasing its longevity.

A5. Some cutting software are coded to work on specific, particular types of plotters only. Others can be used on different types of plotters. The software depends on the kind of project given the input.