All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(929 products available)

An optical circulator is a sophisticated photonic device used for routing optical signals in communication systems. Built to improve data throughput and efficiency, this device has become essential in the telecommunications industry, particularly in fiber-optic networks. Its workings are deeply rooted in advanced physics and materials science, making it a focal point for research and development in high-speed data transmission technologies.

Particularly, an optical circulator routes light in a non-reciprocal manner, meaning it can direct incoming light to an outgoing port while preventing backflow to the originating port. This unique capability enables multiple data channels to operate simultaneously over a single fiber, thereby maximizing bandwidth. Such features make optical circulators indispensable for constantly increasing network demands and cutting-edge technological applications.

Here are the various types of optical circulators:

Single-D port optical circulator

A single-D port optical circulator is a three-port device that allows light to pass from port 1 to port 2 while directing any returning light at port 3 away from port 2. Key features include simple architecture and low insertion loss, making it ideal for basic applications like fiber optic sensor networks. Its energy-efficient design and compact size allow for easy integration into existing systems. The device is usually made of glass or specialized crystals that provide the necessary non-reciprocal function. It finds application in systems where basic signal routing is needed without complex requirements.

Multi-port optical circulators

Multi-port optical circulators are advanced devices capable of routing light signals through multiple channels. These circulators, unlike the three-port model, are designed to route signals sequentially through several ports, enhancing system complexity and functionality. They are especially vital for applications in wavelength division multiplexing (WDM) and sensor networks, where multiple signals need to be managed efficiently.

The primary advantage of multi-port optical circulators is their ability to maximize the use of a single fiber optic line by allowing multiple data streams to pass through without interference. This feature significantly increases system capacity and efficiency, making them a preferred choice in high-demand environments like telecommunications networks, where space and infrastructure are critical.

Polarization maintaining optical circulators

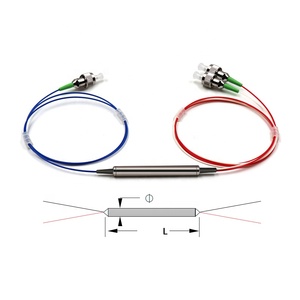

Polarization-maintaining optical circulators (PM-OCs) are specialized devices that preserve the polarization state of light as it passes through them. Unlike standard circulators, PM-OCs maintain the orientation of light waves, making them ideal for applications sensitive to polarization changes, such as fiber sensors and high-performance communication systems. The main features of PM-OCs include precise polarization control, low insertion loss, and high thermal stability.

Wideband optical circulators

Wideband optical circulators are designed to operate over a broad range of wavelengths, unlike standard circulators optimized for specific wavelengths. This capability allows wideband circulators to be used in various frequency bands and technologies, including telecommunications, sensing, and astronomy. One of the critical features of wideband optical circulators is their ability to maintain low losses across multiple wavelengths, ensuring efficient signal transmission.

Optical fibers

Optical circulators play a vital role in the optical fiber industry by enhancing the capacity and efficiency of fiber optic networks. They are used to route signals efficiently, enabling the transmission of multiple data streams simultaneously over a single fiber. By allowing bidirectional communication without interference, optical circulators help maximize bandwidth and speed, making them critical in telecommunications.

Fiber lasers

Optical circulators are crucial in the fiber laser manufacturing process. They help in controlling the light within fiber laser systems, improving stability and output power. By managing the signal directions, circulators allow for more efficient pumping and reduce energy losses, leading to robust and high-performance fiber lasers used in various industrial cutting and welding applications.

Fiber sensing

In the fiber sensing field, optical isolators are used in sensors to monitor temperature, pressure, and strain. They help in protecting the sensor signals by preventing the back reflection of light, which could cause interference or damage to the system. This functionality is particularly useful in structural health monitoring and industrial process control applications, where precision in measurements is crucial.

Telecommunications

Circulators are used to separate and route signals from multiple transmission channels, enabling systems like wavelength division multiplexing (WDM) to function. In this way, optical circulators enable telecommunications systems to transmit more data over longer distances without signal degradation, leading to better performance and reliability.

Aerospace applications

The aerospace industry depends on the performance and reliability of communication and monitoring systems. In this, optical circulators are used in fiber-optic communication systems to ensure robust data transmission. They also find uses in sensors that monitor critical parameters such as altitude and speed. The ability to operate effectively in harsh environments, including extreme temperatures and radiation exposure, makes them suitable for space missions and satellite systems, where failure can be costly or life-threatening.

Optical circulators are important devices that have become key elements in sophisticated photonics and telecommunications systems. Various fiber circulators, with unique architectures and operational principles, enable these devices to effectively manage the propagation of optical signals through multiple ports. The following segment discusses the significant architectural features of these devices that define their functionality and usefulness.

The main function of the optical fiber circulators is to direct incoming light from one port to the next while preventing backward transmission. Fiber optical isolators utilize non-reciprocal light transmission features based on magneto-optic effects or other nonlinear optical phenomena. These can be achieved through different configurations, each suited to particular applications and performance requirements.

Single-port or three-port circulators are simple, with basic signal-routing capabilities. In contrast, more complex systems, such as polarization-maintaining and wideband circulators, accommodate more ports and operational modes to fulfill advanced application requirements, like sensing or DWDM (Dense Wavelength Division Multiplexing) systems that need precise control over multiple optical signals. This device architecture directly impacts its performance metrics, such as insertion loss, return loss, wavelength sensitivity, and operating ranges, bandwidth, and temperature stability.

Here are the device specifications:

Operating wavelength. This defines the range of wavelengths over which an optical isolator can operate effectively. Therefore, the circulator's bandwidth needs to coincide with the operating wavelengths of the desired optical system.

Polarization dependence. Polarization-maintaining circulators must preserve the polarization state of the light to function well. Thus, this feature is important for fiber optic sensors and other systems that are polarization-sensitive.

Port count. The number of ports in a circulator decides the complexity of the optical system it can handle. Simple three-port circulators are used for basic applications, while more complex models are needed in advanced telecommunications systems.

Installing and using an optical circulator requires technical skill and close attention to detail to guarantee optimal performance within fiber-optic systems. The following steps outline the general procedures for properly placing and using these instruments:

Pre-installation assessment

Before installing, evaluating the system's requirements and choosing the right optical coupler for the intended use is necessary. Consider factors like the number of needed ports, operating wavelength, and polarization sensitivity. In addition, one must conduct an assessment of existing fiber-optic infrastructure to assess compatibility.

Mounting and alignment

Following the pre-installation evaluation, mount the optical splitters onto a stable surface inside a protected environment where its elements are shielded from dust, vibration, and moisture exposure. Align the ports of the circulator with the incoming and outgoing fiber-optic cables to ensure proper light coupling into the system. Use a fiber cleaver to create smooth fiber ends that guarantee a tight and even splice.

Splicing

Once the cables are aligned, splice them together using either a fusion splicer or a mechanical splice. Proper splicing is key here, as any mismatch or poor connection will give rise to insertion loss and signal degradation. After this, one is to protect splices with heat-shrink tubing or other suitable splice enclosures to prevent cable damage in future.

Testing

After installation, the system must be tested with an optical cable testerto assess performance. This involves checking signal strength, loss levels, and all circulator functionalities. Power meter and light source or optical performance analyzer will do this. Run these tools to measure to crosscheck that all ports are properly functioning and that insertion loss and return loss are within spec limits. Prompt correction of any identified issues like misalignment or poor splicing is necessary to avoid defects or performance issues.

Monitoring

One must periodically monitor the system after successful testing. Regular checks of signal levels and circulator performances, along with preventative maintenance acts like cleaning and periodic re-calibration where necessary, will improve the longevity and continued effectiveness of the optical circulator in fiber-optic systems.

When it comes to choosing an optical circulator, quality and safety become paramount because even the smallest errors in the devices can result in huge losses. Hence, one must pay attention to several important quality factors and implement some basic safety measures below.

Work precision

High-quality optical circulators have a high work precision level, which means they can operate effectively with minimum losses or errors. So, look for key performance metrics like insertion loss, return loss, and isolation. These parameters directly affect the overall performance of the optical system.

Material quality

Optical circulators are made from materials of different qualities, and each performs differently. Good-quality optical circulators are made of premium materials, such as advanced glass or ceramic, which ensure better stability and performance. These materials have high resistance to temperature changes and ensure that the circulators maintain their functional parameters.

Temperature stability

Optical circulators are used in various environments, and one has to ensure that the circulators remain functional at different temperatures. Go for one with high thermal stability; such quality circulators will keep their performances even at extreme temperatures. This ensures the devices remain effective no matter how hot or cold an environment they have been put in.

Test and validation

One must consider whether the manufacturers of the chosen optical circulators have undergone rigorous testing and validation to back up their performances. Not only tells one about the robustness of the product but also offers guaranteed reliability over time.

Habitat keeping

Optical cable circulators are delicate, and any harshness can lead to circulator failure or poor performances. Therefore, maintaining a clean habitat free from dust, moisture, and other contaminants is crucial.

Shock

Optical circulators are sensitive and can give unreliable readings or no output if exposed to shock. And while handling, transporting, or installing these circulators, one must exercise care not to subject them to any physical shock.

Sensitivity to high-power lasers

Circulators can be damaged if the input power level exceeds their rated capacity. Always verify that the input power levels remain within the specified range to prevent laser damage to the circulator.

Sensitivity to high-temperature

Circulators can be damaged or malfunction if exposed to temperatures above their specified operating range. Optical circulators fitted in high-heat environments should be adequately shielded or cooled to mitigate heat exposure.

A1. An optical cable joint is used in telecommunication to route optical signals through to the intended ports within the fiber-optic system while preventing signal back reflection from porting to the originating port. This unique capability allows for the efficient transmission of multiple signals over a single fiber, enhancing system bandwidth and performance.

A2.Like the name suggests, optical isolators are meant to isolate light, but optical circulators are for signal routing. While isolators block back-reflection of light, which could cause interference, optical circulatorsdirect the light through to the intended output port, which has the advantage of increasing signal throughput within fiber-optic networks.

A3.Indeed. Optical circulators can work with both single-mode and multimode fibers, provided that the circulator is properly designed to accommodate the core diameter differences. Those meant for single-mode fibers are usually used in long-haul telecom applications, whereas those for multimode fibers are ideal for shorter distance within-building applications.

A4.Industries that depend on high-speed data transmission, such as telecommunications, aerospace, and defense, along with those employing fiber-optic sensors for structural health monitoring and industrial process control, and even medical imaging and laser manufacturing, all enjoy the immense benefits of using optical circulators in their operations.

A5.A polarization-maintaining optical fibre coupler preserves the light polarization state as it routes the signal through. This is achieved through specially designed waveguides that maintain the polarization orientation. Therefore, this feature makes PM-OCs particularly useful for fiber-optic sensing and other applications requiring precise control of the light's polarization state.