All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(1288 products available)

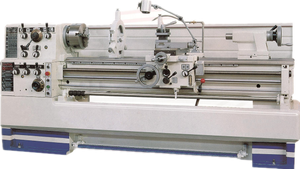

An on-car brake lathe machine is a tool used to repair brake rotors. It helps to ensure that the brake pads and brake rotors have an even surface. This makes sure that the friction between the brake pads and brake rotors is even. The on-car brake lathe machine is mounted on the vehicle's brake system. It has a cutting tool that will move back and forth. This tool will remove any material from the brake rotor. As it removes material, it shapes the brake rotor into an even surface. There are different types of on-car brake lathe machines. They include:

Different countries have different rules and regulations concerning on-car brake lathe machines. Some countries require the on-car brake lathe to be certified. This is to make sure that the brake rotor machining meets the required standards.

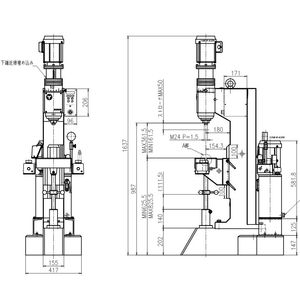

Specifications of on-car brake lathe machines include:

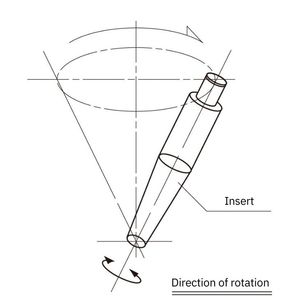

Cutting Tools

Cutting tools on car brake lathes are made from durable materials such as carbide or high-speed steel. The tools have sharp edges that are used to remove imperfections from brake rotors. They come in different shapes and sizes to accommodate various rotor designs. Frequent inspection and replacement of worn-out tools is necessary to maintain optimal cutting performance.

Adjustment Mechanisms

These lathes have adjustment mechanisms that enable operators to set the cutting depth and speed. The mechanisms include fine adjustment screws or digital displays. Maintenance involves regular calibration, cleaning of the adjustment components and lubrication.

Motor

The motor provides power to the on-car brake lathe. It is advisable to use a motor that is adequately powered to handle various rotor materials and sizes. Regular inspection and cleaning of the motor are necessary to prevent wear and tear.

Cutting Speed

Different on-car brake lathes have various cutting speeds. The speed should be suitable for the rotor material. Routine checks are necessary to ensure the cutting speed is even and consistent.

Vibration Control

Brake lathes are designed with vibration control features. These features include dampers or specialized components that minimize vibrations during the machining process. For vibration control features to work effectively, they need to be clean and securely mounted.

Power Supply

Power supply refers to the electrical components that supply power to the on-car brake lathe. These include cords, plugs, and switches. The electrical components should be regularly inspected to avoid damage and ensure proper operation.

Cooling System

The cooling system aids in regulating temperature during machining. It prevents overheating, which can lead to damage to rotors or the brake lathe itself. Regular checks are necessary to ensure the cooling system components are clean and free from obstructions.

Frame

The frame is the on-car brake lathe's external structure that holds all components together. The frame should be sturdy and free from damage. Routine inspections should be conducted to assess the on-car brake lathe frame for cracks or wear.

Maintenance of on-car brake lathes is essential. Here are some of the maintenance requirements:

Choosing a brake lathe is no easy task. There are several factors to consider. Here are some of the key factors:

The very first thing to consider is the budget. Determine how much money is available for purchasing a brake lathe machine. Remember that the cost of the machine is just the beginning. There will be other costs, such as the cost of maintenance and operation.

Another factor to consider is the space. Check the workshop space to see if there is enough space for a new brake lathe machine. Different machines have different sizes and require a specific amount of space for operation and safety.

Consider the power source and the noise level of the machine. Some machines are powered by electricity, while others use hydraulic or pneumatic power. Hydraulic and pneumatic machines provide more power but are noisy and require more maintenance.

The maintenance and operation costs are important factors to consider when choosing a brake lathe. Some lathes have low maintenance costs and are easy to operate, while others are costly to maintain and require skilled operators.

Choose a brake lathe with a low vibration level. High vibration levels can cause damage to the brake components and the machine itself. Also, ensure the machine is safe and comfortable to use.

When choosing a brake lathe, consider the versatility and accuracy. A versatile machine can handle different types and sizes of brake components, while an accurate machine ensures precise and consistent results.

Finally, check the reviews and reliability of the brake lathe. Choose a machine with high reliability and consistent performance. Also, read the reviews to see what other users are saying about the machine.

Most brake lathes are designed with the operator in mind, so they are easy to operate. The brake lathe operator must have the necessary skills and knowledge to handle a brake lathe machine. Below is a step guide on how to operate a brake lathe:

Inspection of the brake disc or drum:

The first step is to inspect the brake disc or drum to check for any visible damage. After that, a thickness measurement will be taken to determine the appropriate lathe settings.

Setup the brake lathe:

The operator sets up the brake lathe according to the manufacturer's instructions. This includes selecting the right cutting tools, securing the workpiece (disc or drum), and adjusting the speed and depth of cut.

Cutting:

During this process, the operator starts the cutting process, gradually increasing the speed and ensuring a smooth and even cut. Also, they regularly check the workpiece to ensure it meets the desired specifications.

Finishing:

At this stage, the operator stops the machine and inspects the workpiece surface. They adjust the cutting tools if necessary to achieve the required surface finish and evenness.

Quality control:

The operator measures the workpiece after finishing to confirm it meets the required specifications. If it does not meet the specification, the process is repeated until the desired result is achieved.

Cleaning:

After the operator is done with the cutting and finishing processes, they clean the brake components and the surrounding area to remove any debris or dust generated during the operation.

Final inspection:

The operator performs a final inspection to ensure everything is in order and the brake components are ready for reinstallation.

Q1: Can one person operate a brake lathe?

A1: Yes, typically, one person can operate a brake lathe. Once the workpiece is set and the machine is programmed with the necessary parameters, the lathe will carry out the machining process automatically. However, monitoring is required to ensure everything operates smoothly and to make any necessary adjustments.

Q2: What does a brake lathe technician do?

A2: A technician operating a brake lathe is responsible for maintaining and repairing brake discs and drums. They utilize brake lathes to restore worn or damaged braking components to their original specifications, thereby enhancing vehicle safety and performance.

Q3: Is it difficult to operate a brake lathe?

A3: Operating a brake lathe is not inherently difficult, but it requires some level of skill and understanding. Users must comprehend the principles of machining, the operation of the brake lathe, and the characteristics of various materials to achieve optimal results.