Types of Nitrogen Inflator Machines

A nitrogen inflator machine uses liquid nitrogen to fill up tires. Because of the low temperature of liquid nitrogen, tire nitrogen inflation is better than air inflation. The inflator machine has also been adopted by many tire shops and dealerships. Some of the common types of nitrogen inflator machines are as follows.

-

Portable Nitrogen Tire Inflator

The portable nitrogen tire inflator is handheld and easy to carry. It can be powered by a vehicle's 12V power outlet. The inflator also has an LCD display that makes it easy to read pressure levels. It has built-in accuracy sensors that detect changes in pressure. Some models of the portable nitrogen tire inflator also have automatic shut-off features.

-

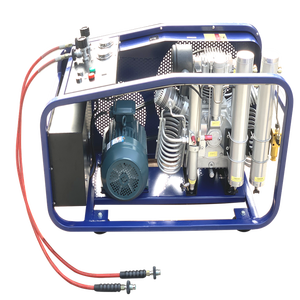

Commercial-grade N2 tire inflators

Commercial-grade N2 tire inflators are for high-volume applications like tire shops or dealerships. They have high flow rates that allow them to fill multiple tires quickly. The inflators also have large nitrogen tanks for continuous operation. Additionally, they have advanced filtration systems that remove moisture and impurities from the nitrogen. Commercial-grade N2 tire inflators also have digital control panels for easy operation.

-

Racing Nitrogen Tire Inflator

Racing nitrogen inflators are designed for motorsport teams and high-performance vehicles. The inflators are lightweight and portable. They come with custom cases for transportation. Racing nitrogen tire inflators have gauges with high accuracy.

-

Wall-mounted nitrogen tire inflators

These machines are installed on the wall or a nitrogen cabinet. They are designed for service stations and tire workshops. The inflators come with pressure regulators and flow controls. They also have safety features like pressure relief valves.

Specifications and maintenance of nitrogen inflator machines

A nitrogen tire inflator is a machine used to fill tires with nitrogen gas. Below are the specifications of a nitrogen inflator machine:

- Power supply: A nitrogen inflator requires a power supply to operate. The power supply could be from the car battery, mains electric supply, or rechargeable batteries.

- Pressure gauge: The pressure gauge is a very important part of the nitrogen inflator machine. It is used to measure the pressure of the nitrogen in the tire. The operator can see the tire pressure on the display screen of the pressure gauge. Some advanced nitrogen inflator machines have an automatic stop feature that stops the inflator when the desired pressure level is reached.

- Hoses and tire chucks: The nitrogen inflator machine has specialized hoses and tire chucks that connect the inflator to the tire. The hoses are used to transport nitrogen from the inflator to the tire, and the tire chucks are used to secure the bond between the tire and the inflator, preventing the nitrogen from leaking.

- Flow rate: The flow rate of the nitrogen inflator machine is how fast the nitrogen is filled into the tires. A higher flow rate means the operator can complete the job faster. The flow rate of a nitrogen inflator machine is typically between 5 and 10 liters per minute.

- Adjustable pressure settings: The nitrogen inflator machine has different pressure settings that suit different tire sizes and types. The adjustable pressure setting allows the operator to set the desired pressure level for each tire. The pressure settings of a nitrogen inflator machine range from 20 to 50 psi.

Below are the maintenance tips for a nitrogen inflator machine:

- Cleanliness: Keeping the nitrogen inflator machine clean is very important. After every use, dirt and debris should be cleaned from the machine, including the hoses, tire chucks, and nozzles. This will prevent the build-up of debris, which could affect the performance of the machine.

- Regular inspection: The nitrogen inflator machine should be regularly inspected for wear and damage. The hoses, tire chucks, and nozzles should be checked for cracks and leaks. If any parts of the machine are damaged, they should be replaced immediately.

- Lubrication: The moving parts of the nitrogen inflator machine should be lubricated regularly to ensure they run smoothly. A lubricant recommended by the manufacturer should be used. The moving parts of the machine should be lubricated according to the manufacturer's instructions.

How to choose a nitrogen inflator machine

Business owners should consider several factors when purchasing a nitrogen tire inflator. These factors help ensure that the device meets the specific needs of the target customers. Key aspects to evaluate include the following:

- Portability: The size and weight of a nitrogen inflator machine can affect its portability. A portable inflator is more convenient for roadside assistance services and customers who frequently travel long distances. Weighing a portable nitrogen inflator machine should be less than 5 lbs (2.27 kg).

- Accuracy: The inflator's pressure gauge should have a high degree of accuracy to ensure that tires are inflated to the recommended pressure. Inaccurate gauges can lead to overinflation or underinflation, which can affect tire performance and safety.

- Noise level: Consider the noise level of the nitrogen inflator. Inflators with quieter operation are more convenient for sensitive environments or residential areas.

- Power source: Nitrogen tire inflators can be powered by different sources. For example, some are powered by the vehicle's 12-volt outlet, while others are battery-operated or plug into a standard electrical outlet. Tire inflators powered by the vehicle's 12-volt outlet are more portable and convenient for roadside use.

- Accessibility: The location of controls and the visibility of the pressure gauge can affect the ease of use. Controls that are easy to reach and a gauge that is clearly visible can make tire inflation more convenient and accurate.

How to DIY and replace nitrogen inflator machine

It is important to always have a nitrogen inflator machine. It's easy to install and use. Here is the guide on how to use a nitrogen tire-inflating machine.

- 1. Vehicle Preparation and Safety: Before starting the inflation process, ensure that the vehicle is parked in a safe area away from traffic. Turn on the hazard lights and ensure the parking brake is engaged. Additionally, make sure the tires are in a condition that allows for safe driving after inflation.

- 2. Removing the Tire Valve Cap: To begin inflating a tire with the nitrogen machine, first remove the plastic cap from the tire valve. Keep this cap in a safe location to prevent it from falling and getting lost.

- 3. Attaching the Inflation Gun: The inflation gun, which is connected to the nitrogen machine, is placed directly onto the tire valve. This establishes a connection between the machine and the tire, allowing for controlled inflation.

- 4. Pressing the Lever to Inflate: A lever located on the inflation gun is pressed to initiate the tire inflation process. This action opens the internal valve, allowing nitrogen gas to flow into the tire. Simultaneously, the built-in pressure gauge begins to monitor and display the tire's pressure in real-time.

- 5.Adjusting Nitrogen Flow: Depending on the specific requirements of each tire, the nitrogen flow can be adjusted. This is done using the dial located on the inflation gun. By turning the dial, the operator can increase or decrease the rate of gas transfer, ensuring precise and efficient tire inflation.

- 6. Tire Pressure Monitoring: Throughout the inflation process, the operator should consistently monitor the pressure gauge's reading. This provides real-time information about the tire's pressure, allowing for adjustments as necessary to maintain the recommended specifications.

- 7.Reaching the Desired Pressure: Once the tire reaches the desired pressure, typically indicated by a steady gauge reading, the inflation process is considered complete. Pressing the inflation gun's lever will stop the valve's operation, ceasing the nitrogen flow.

- 8.Removing the Inflation Gun and Replacing the Valve Cap: After completing the inflation process, the inflation gun is carefully removed from the tire valve. At this point, it is crucial to promptly reattach the valve cap to prevent contamination and maintain the nitrogen's purity within the tire.

Q and A

Q1: How long does a nitrogen inflator last?

A1: The longevity of a nitro inflator depends on various factors. This includes the frequency of its usage and its maintenance practices. Generally, a well-maintained nitrogen inflator can last for several years. Some manufacturers also indicate the lifespan of a nitrogen inflator. They may show the number of cycles or uses before the machine will wear out.

Q2: Why do people prefer nitrogen tires?

A2: Many people prefer tires filled with nitrogen because of its stability. The tires remain inflated for a long time when the drivers use nitrogen. The good thing with nitrogen tire inflation is that it reduces the frequency of tire inflation. It also improves fuel efficiency and enhances vehicle safety.

Q3: Can anyone use a nitrogen inflator?

A3: Yes, everyone can use a nitrogen inflator. It is a simple and straightforward process. Even without prior experience, one can use a nitrogen inflator machine successfully. The manufacturers provide instructions and guidelines to help users understand its operation.