Introduction to Natural Gas Filter Strainers

Natural gas filter strainers are essential components in the natural gas processing and transportation industry. They are designed to protect pipelines, valves, and equipment from contamination and debris that could interfere with safe and efficient operations. By effectively filtering out unwanted particles, these strainers enhance the reliability and longevity of gas systems, ensuring that the natural gas delivered is clean and free from impurities.

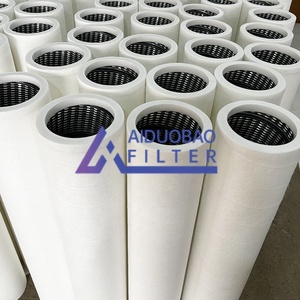

Types of Natural Gas Filter Strainers

Natural gas filter strainers come in various types to suit different applications and operational conditions. Understanding these types can help in selecting the appropriate unit for your needs:

- Basket strainers: Commonly used for larger pipelines, these strainers have a perforated basket that collects debris and can be easily cleaned.

- Y-strainers: Shaped like a ‘Y’, these strainers provide a compact design suitable for tight spaces, ideal for smaller pipelines.

- Pipeline strainers: These are integrated directly into the pipeline, providing continuous filtration without the need for separate housings.

- Magnetic strainers: Utilizing magnetic technology to attract ferrous particles, these are often used when metal contaminants are a concern.

Applications of Natural Gas Filter Strainers

Natural gas filter strainers have a wide range of applications across different sectors, ensuring the integrity and performance of gas systems:

- Oil and Gas Industry: They are vital in upstream operations to protect equipment from sand and other contaminants.

- Power Plants: Natural gas is a primary fuel source; strainers ensure the clean flow of gas to turbines and generators.

- Commercial and Industrial Boilers: Filter strainers prevent debris from clogging burners, improving efficiency and safety.

- Residential Natural Gas Lines: Essential for preventing contamination in home heating systems and appliances.

Advantages of Using Natural Gas Filter Strainers

The incorporation of natural gas filter strainers into gas systems brings numerous advantages that contribute to operational efficacy:

- Enhanced System Efficiency: By removing impurities, strainers assist in maintaining optimal performance levels of downstream equipment.

- Increased Equipment Lifespan: Protecting valves, pumps, and compressors from damage extends their functional life and reduces replacement costs.

- Safety Assurance: Strainers significantly lower the risk of mechanical failures or leaks caused by debris-related obstructions.

- Cost-Effective Maintenance: Regularly maintained strainers minimize downtime and associated labor costs, providing a better return on investment.