All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(4209 products available)

Nano fabrics come in diverse types and each type is selected based on the intended applications. These applications may include textiles for clothing, medical uses, or industrial applications.

These types of nano fabrics incorporate carbon nanotubes into common textile materials. These materials enhance strength, durability, and flexibility in the target fabric. They are lightweight and possess superior tensile strength compared to conventional materials. In addition, CNTs offer conductivity, thus allowing the fabric to be utilized in making self-heating clothes or smart textiles for electronic integration.

This type of fabric integrates metals like silver or copper into the textile fibers. While these fabrics retain antimicrobial properties, they also provide conductivity for unique applications such as anti-static clothing or sensors. Often used in protective clothing, they are also used where sanitation is critical such as in medical or food processing environments.

Biodegradable nano fabrics are developed from natural polymers such as cellulose and chitin. These fabrics are critical in applications where single-use or environmentally friendly materials are required. The nano-coating enhances the materials’ barriers for water and air as well as improving mechanical strength. This significantly contributes to sustainable fashion and disposable medical textiles.

These nano-fabrics contain polymeric matrices with embedded microcapsules. The microcapsules release healing agents upon damage. This leads to enhanced longevity in applications that typically undergo wear-and-tear. This nano-fabric is key in areas like automotive upholstery or activewear, where durability is most critical.

These fabrics incorporate materials that change properties in response to external stimuli. Such stimuli may include heat, light, or electric current. Temperature-regulating fabrics fall under this category. They are commonly used in adaptive clothing for medical applications or space exploration where temperature control is critical.

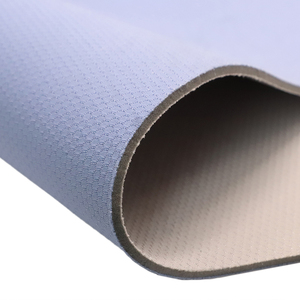

These nano-fabrics merge different materials to leverage the benefits of each. They are usually constructed with one layer providing the structural integrity of the fabric and another layer embedded with nanoparticles. This offers additional functions such as filtration or UV protection. The versatility of composite nano-fabrics allow their use in every domain from sportswear to environmental suits.

Conventionally, the features of nano textiles have been advanced to offer more functionality. Also, they are improving the performance and durability of common fabrics.

This is a predominant feature in nano-textile fabrics. They are extremely water-resistant due to the microscopic size of the fabric's fibers and the resultant reduction in pore size. This ultimately results in improved surface tension. Where is nano fabric used? Nano fabrics are applied in outdoor clothing, tents, and gear for rain and moisture protection, and in home textiles for water-repellent properties.

Often, nano fabrics have stain-resistant properties since they are engineered to resist the penetration of liquids and particles. This is developed by structuring the fibers at the nanoscale, which reduces the adhesion of substances to the fabric's surface. Also, dirt and oil are less likely to be absorbed by nano fabrics. They are commonly used in upholstery, uniforms, and industrial workwear to resist staining.

Many nano fabrics are engineered to maintain breathability despite their advanced protective features. Nano fabrics developed for medical applications, such as wound dressings, allow air and moisture vapor to pass through while blocking bacteria at the nanoscale. Also, in fashion, activewear uses nano fabrics that aid in moisture wicking without retaining sweat on the skin.

Often, one of the key features of nano textiles is their lightweight nature, accompanied by high strength and durability. Notably, carbon nanotube reinforced fabrics are very light, yet immensely strong and resistant to tearing or wear. These make them ideal for use in high-performance applications. Lightweight high-strength fabrics are used in sports gear, outdoor equipment, and personal protective gear like military jackets.

Previously, certain nano fabrics incorporate nanoparticles, such as silver or copper. These are embedded within the fibers to confer antimicrobial properties. This is critical in inhibiting the growth of bacteria and fungi on the fabric. It also extends the life of the textile and keeps it fresh. They are predominant in medical textiles, such as surgical gowns and implants, and in hygiene products such as socks, underwear, and bedding.

Incorporating nanoparticles, these nano fabrics effectively block UV radiation. For instance, titanium dioxide nanoparticles are used to enhance UV-blocking capability. These fabrics protect the skin from harmful rays while remaining lightweight and flexible. Frequently, sun-protective clothing, outdoor gear, and tents rely on the UV-blocking properties of nano textiles.

Nano fabrics are versatile and critical to a wide spectrum of industries. Often, their unique properties are useful for diverse applications.

Nano fabrics are critical for environmental remediation. This is because they usually integrate nanoparticles that absorb or degrade pollutants. Normally, they are applied in water treatment systems for the removal of heavy metals, dyes, and organic contaminants. Their lightweight and high surface area to volume ratio makes them effective in the purification process. In addition, the incorporation of photocatalytic nanoparticles in water filtration aids in the breakdown of pollutants upon exposure to light. This makes them a sustainable choice for environmental cleanup efforts.

In medical applications, nano fabrics are used for making wound dressings with improved healing properties. Usually, they offer better moisture control, gas exchange, and drug delivery systems. Fibers with electrospun nanofibers enhance tissue engineering scaffolds promoting cell growth and tissue repair. Nano fabrics are also critical for making antimicrobial implants to minimize infection risks.

Customarily, nano fabrics significantly improve the effectiveness and comfort of personal protective equipment (PPE). This includes masks and suits. More critically, they incorporate particles that filter airborne toxins while remaining breathable. For example, masks containing graphene nano fabric filter >90% of particulate matter without moisture retention.

Nano fabrics are crucial in creating high-performance airtight and waterproof clothing in extreme environments or space. Normally, these fabrics integrate layers of nano-coated membranes that block water molecules while allowing vapor exchange. In addition, they ensure dryness and comfort during prolonged wear. Often, this application is especially critical for astronauts and outdoor adventurers who depend on reliable protection from the elements.

Often, coatings incorporate nano-sized particles to enhance fabrics with water and stain resistance, UV protection, and antimicrobial features. Customarily, nanoparticles like silica or titanium dioxide are integrated into textile fibers to develop durable surfaces. These resist pollutants, bacteria, and other threats. In addition, the nanoparticles improve the fabrics' mechanical strength and longevity, thereby lessening the need for toxic chemicals in textile treatment and reducing environmental effects.

These allow real-time monitoring of vital signs such as heart rate and respiratory patterns using embedded nano fabrics. Usually, nano fabrics like conductive polymers or carbon nanotube-infused textiles are lightweight and flexible, thus making them comfortable for long wear. Also, they maintain conductivity for long. These are critical in smart healthcare systems. They allow early detection and chronic condition monitoring without complex devices.

Here are some crucial factors to consider when purchasing nano-coated fabrics.

Plastics with nano-coating can be comfortable and breathable. Business owners should look for fabrics with microscopic pores and ask for breathable samples. Buyers should take into consideration reviews and testimonials to spot any past discomfort issues. Business owners should also get fabrics with different comfort/ breathability levels for various applications.

Plastics with nano-coating come in a wide range of types and colors. This offers various benefits to buyers when purchasing them in bulk. For starters, they allow business owners to sell diverse products to different customers. More importantly, they appeal to different customers with diverse tastes. And preferences. Buyers should look for fabric suppliers who offer them customization options and buy fabrics in the popular colors.

Various nano-coated fabrics suit various purposes. For instance, some are designed to protect from weather elements, while others provide warmth. It's important for business owners to get fabrics that are comfortable for their clients and prioritize the intended usage. Moreover, shoppers should get fabrics with multiple uses, such as waterproofing and breathability.

The maintenance level of the organic fabrics with a nano-coating impacts their longevity. Look for fabrics that are easy to care for and wash. Also, consider those that can withstand easy washing without damage. Purchasers should also avoid fabrics that require special care or detergents. To ensure easy maintenance.

Check the durability of the nano-coating. Ideally, it should maintain effectiveness for as long as expected. Buyers should consider the coating method. That is, bonded coatings are more durable than coated by spraying. In addition, fabrics with scratch-resistant coatings are ideal as they can handle harsh conditions and are long-lasting.

Nano fabrics can be heated. Their microscopically thin fibers provide excellent insulation. This makes them ideal for temperature control applications. For instance, some smart textiles use nano fabric to retain body heat while remaining lightweight and breathable. Often, a nano fabric serves as heating elements in dynamic environments. Normally, controlled heating in such fabrics offers comfort without excess weight or bulk. In addition, they are distinguished by their quick response to temperature changes.

Nano fabric incorporates fibers with a diameter of less than 1 micron, while regular fabric consists of thicker fibers. The former offers superior durability, water resistance, and breathability. They are lightweight, stronger, and possess advanced features such as self-cleaning and antimicrobial properties. Regular fabrics, on the other hand, have conventional properties and are heavier. Also, they are weaker and lack most of the innovative functions of nano fabrics.

Some forms of nano-coated fabrics can be beneficial to the environment. For example, superhydrophobic nano fabrics can reduce water usage during washing and minimize water pollution. Also, some nano coatings enhance fabric durability. Thus extending the lifespan of textiles and reducing waste. In addition, they can provide protective functions without the need for toxic chemicals. Customarily, the environmental impact of nano fabrics relies on the materials and processes used in their development. Therefore, sustainable practices in producing nano fabrics are critical to reducing their ecological footprint.

To clean nano fabrics, hand wash them in cold water with a mild detergent that doesn't have any harsh chemicals. Avoid fabric softeners and bleach and don't use them under direct sunlight. Ideally, let the fabric air dry it in the shade then store it in a cool place.

The nano coating can be repaired. However, the process is intricate and often not as straightforward as traditional repairs. Usually, specialized repair kits or treatments are required to restore the nano-coating effectively. Sometimes manufacturers offer services to repair or regenerate the coating. Also, some newer technologies are in development to simplify the repair process for consumers.