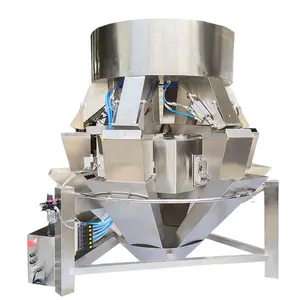

Introduction to Multihead Weighing Scale

The multihead weighing scale is an advanced machine designed primarily for high-speed and precise weighing applications in various industries. With the ability to weigh products of different shapes and sizes accurately, this technology is essential for enhancing productivity and efficiency in manufacturing and packing operations. The multihead weighing scale features multiple hoppers that work simultaneously, providing high throughput and minimizing operational downtime.

Types of Multihead Weighing Scales

Multihead weighing scales come in various designs to cater to diverse industry requirements. The following are the main types:

- Standard Multihead Weighing Scales: Ideal for general applications, offering flexibility for multiple product types.

- High-Speed Multihead Weighing Scales: Engineered for rapid output, perfect for high-demand environments like food packaging.

- Mini Multihead Weighing Scales: Designed for smaller production lines, suitable for tiny products or low quantities.

- Multihead Weighing Scales with Specific Applications: Tailored for industries such as pharmaceuticals, confectionery, and snacks, addressing unique challenges.

Applications of Multihead Weighing Scale

The multihead weighing scale is versatile and finds use across numerous sectors. Its broad applications include:

- Food and Beverage: Commonly used for weighing ingredients in terms of accuracy and hygiene, ensuring precise portion control for various products.

- Pharmaceutical: Essential for precise dosage in manufacturing processes, particularly critical for tablets and capsules.

- Cosmetics: Applied in precise packaging of cosmetic ingredients, ensuring uniformity and quality.

- Packaging Industry: Ideal for optimizing packing speeds while handling bulk materials, enhancing operational efficiency.

Features and Advantages of Multihead Weighing Scales

Multihead weighing scales are equipped with numerous features that enhance their functionality and efficiency. Some of the standout features and advantages include:

- High Precision: Advanced sensors ensure accurate weighing with minimal errors, critical for quality control.

- Speed: The multihead system allows for rapid processing, effectively increasing output compared to traditional scales.

- User-Friendly Interfaces: Most models come with intuitive controls, making operation simpler, and minimizing training time for staff.

- Flexible Setup: Capable of handling diverse products, from small pellets to larger items, allowing for adaptation to changing production needs.

- Durability: Constructed with robust materials, ensuring longevity and reliability in demanding environments.

- Data Management: Many multihead weighing scales feature integration with software systems, facilitating monitoring, data collection, and analytics for improved performance.