(12 products available)

Mitre bend pipes are manufactured to enable sharp directional changes when connecting two pipelines. Depending on the materials used, the purpose of the mitre bend, and the technology required to manufacture the bend, mitre bends can be classified into several distinct pipe types.

Materials

Mitre bends can be manufactured out of the same materials as the pipes they connect. This is essential when following industry regulations and certain(section 2 Article 5)technical standards.) For instance, in plumbing and construction applications, copper mitre bends are commonly used to connect copper pipes, particularly in systems where high performance and low thermal expansion are required. Plastic mitre bends, usually made from PVC, CPVC, or other specialized polymer materials, are typically lightweight, noncorrosive, and easy to install. They are commonly used in low-pressure applications such as drainage and irrigation systems. Stainless steel is favored in high-performance, high-pressure, and corrosive environments.

Function

Mitre bends can also separate into two main types depending on the angle of inclination. Low-angle mitre bends are used with high-mitred bends, but they are not distinct types.

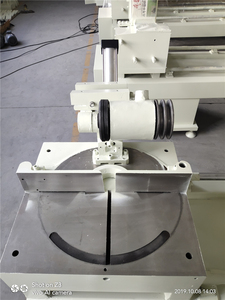

Manufacturing Technology

The process of making a mitre bend usually involves welding, casting, stamping, or extrusion, as described in detail in other sections. This creates an additional distinction among mitre bends. Welding involves the joining of two or more pieces after shaping; the other methods create the bend in one solid piece. Welded bends could have several types depending on how the pieces are joined.

Some of the common specifications of mitre bends for pipes are as follows:

Material

Various materials are used for mitre bends based on the application. For example, UPVC is often used in plumbing, while carbon steel might be used in industrial settings. It is essential that the mitre bend pipe is made of a material that can handle the pressure and temperature of the application's requirements.

Angles

Mitre angles in pipes are comparable to mitre angles in pipes. Different mitre angles are used for different purposes. The most common angle is a 45-degree mitre bend. This angle is used for a mitre bend that provides cushioning for elbows between pipes. Other angles, such as 11.25, 22.5, and 30 degrees, can also be used but are not as common as 45-degree mitre bends.

Diameter

Mitre bends come in different pipe diameters. The diameter of the mitre bend is important because it has to match the diameter of the pipes that are being used in a particular plumbing system. The most common diameter options are 1/2'', 3/4'', 1'', 2'', and so on.

Radius

The radius of a mitre bend pipe refers to the curvature of the bend. Most mitre bends have fixed radii, but custom radius options may be available. The radius of a mitre bend might affect the mitre bend's flow capacity and how easily fluid can go through it.

Pressure Rating

Every mitre bend has a pressure rating. This indicates the maximum pressure the particular mitre bend can handle. The pressure rating depends on the material and the construction of the mitre bend.

Mitre bends for pipes need proper care so that they can provide support for connections and last a long time. Here are some strong tips for taking care of mitre bends:

Mitre bends are widely used in the construction and plumbing industries. Some examples include but are not limited to the following:

When selecting mitre pipes for sale, it is crucial to ensure quality and variety while also considering attractive wholesale prices. Buyers might be interested in how the mitre pipes are made and want to purchase mitre pipes of various angles and sizes for different uses.

As mentioned earlier, mitre pipes are manufactured using various methods. In the table below, buyers can see the different manufacturing methods, depending on whether the material is rigid, flexible, or both.

A variety of mitre pipes is essential since they are used in different applications. Buyers would like to see mitre pipes with the following angles:

Besides variety, buyers are also concerned about quality. To meet the market demand, buyers should source pipes made from high-strength material. Buyers are also looking for pipes that are corrosion-resistant, heat-resistant, and weldable. In this case, steel mitre pipes will be preferable, as they exhibit desirable qualities that buyers want. However, even with steel mitre pipes, buyers should get those with durable galvanization, reliable coating, and uniform layer.

If buyers are purchasing mitre pipes to resale, they have to consider the packaging options their customers will prefer. Buyers should look for optional packages of individual pipes, bulk packaging, or customized packaging. A bulk package with a baling wire is cost-effective for those looking for a wholesale price.

Since customers are interested in mitre pipes that work with standard valves and flanges, buyers should request samples to see if they are compatible. They should also request technical data sheets and catalogs so that their customers will have all the details they need about the mitre pipes.

Q1: How are mitre bends different from elbows in piping?

A1: Mitre bends are straight cuts at an angle, while elbows are rounded curves. Sharp angles create turbulence in the flow, while smoother curves reduce turbulence.

Q2: Why are mitre bends considered challenging in piping design?

A2: Mitre bends require precise angles and measurements to achieve proper fitting. They are more complicated to fabricate compared to standard elbows or bends.

Q3: What materials are used for pipe mitre bends?

A3: Materials depend on applications. Common options include steel, PVC, copper, carbon, alloy, stainless material, etc. Sometimes, non-standard mitre pipes are made by coating or lining specific materials within the pipes.

Q4: Can mitre bends affect flow dynamics in a pipeline?

A4: Yes, the type of bend used and its angle can create turbulence or smooth flow. Acute mitre bends may cause more turbulence than gradual bends.

Q5: Are mitre bends available in custom sizes?

A5: Yes, suppliers can fabricate custom mitre bends according to specific requirements. B2B buyers can provide specifications and dimensions.