(55024 products available)

Mining drill bits are specialized tools designed to penetrate geological formations to extract minerals. There is a diverse range of drill bits created for mining, and each one is suited for various kinds of geological formations, penetration depths, and mining methods.

Roller-cone bits

This mining bit is used in soft to medium-hard rock formations and consists of two or three cones. These cones have three fixed teeth on them that roll during the drilling process. The bit creates a trough, typical of the teeth's interaction with the rock, as it penetrates further into the ground.

Drag bits

Drag bits are mining drill bits designed for use in soft to medium-hard rock formations. They consist of a sturdy body outfitted with tungsten carbide, steel, or diamond-impregnated drag teeth. The teeth literally ''drag'' across the rock when the bit is lowered into the well or borehole. The previous action creates fractures in the rock, allowing it to be excavated further.

PDC bits

These bits are made up of a composite of polycrystalline diamond, which gives them excellent durability as well as high-performance levels. PDC bits are commonly used in mining operations with fixed cutter design. These PDC bits are great for longer drilling intervals in medium to hard rock formations.

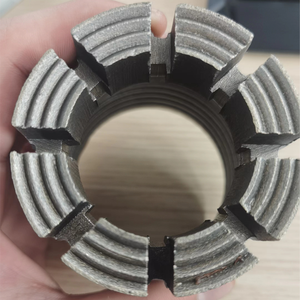

Diamond bits

Diamond bits are the most common type of mining drill bits, and they are well suited for hard rock formations. They typically consist of a bit body outfitted with industrial PDC or natural diamond crowns. Crown is the term used to describe the bit section that is used for drilling. Diamond bits work by having the diamond-framed segments on their surface create a borehole as they rotate. Some diamond bits come with a hollow center that allows for cooling and flushing of drill cuttings.

Downhole hammer bits

This bit is also known as ''DTH'' bits for short, and they are used in conjunction with downhole hammers in percussive drilling systems. DTH bits are great for high-impact drilling in hard rock formations. They work by delivering impacts to the rock on a lightweight and replaceable insert called a carbide button. The carbide buttons on DTH bits can come in various face geometries and sizes to suit different drilling applications.

The specifications of mining drill bits highlight the key characteristics of drill bits used for different types of mining. The following table summarizes key details about drill bits along with their maintenance requirements:

| Mining drill bits | Specifications | Maintenance |

|---|---|---|

| Diamond drill bits |

|

|

| Tricone drill bits |

|

|

| Hammer drill bits |

|

|

| Drag drill bits |

|

|

| Auger drill bits |

|

|

Mining bits are used in several industries apart from mining and tunneling. Here is a list of their applications:

Mining Industry

As the name suggests, drill bits are primarily used in the mining industry. Drill bits are used to create tunnels and shafts to extract minerals like coal, metallic ores, or gems. Core sampling bits are used to gather samples to determine the quality and quantity of minerals present before investing in full-scale mining operations.

Construction Industry

In the construction industry, blast bits are used in controlled blasting to break large rock formations or concrete. This creates space for building foundations, roadways, tunnels, or other infrastructure projects.

Geotechnical Engineering

Geotechnical engineers use bit sampling bits to investigate soil and rock conditions for engineering projects. The samples help determine the stability of the ground and inform the design of foundations, slopes, and retaining structures.

Environmental Monitoring

Environmental scientists may use core sampling bits to collect soil or sediment samples from subsurface formations. These samples are analyzed to monitor and assess contamination, pollutant dispersion, or geological processes.

Oil and Gas Exploration

As mentioned earlier, there are specific drill bits used to extract oil and natural gas from the earth's crust. However, the bits used for these extractions are different from the standard mining bits. In the search for fossil fuels, specialized bits are used to penetrate rock layers and create wells for oil and gas extraction.

When selecting the right set of mining drill bits, several factors will need to be taken into consideration, like the specific needs of the drilling project, the type of material to be drilled through, the drilling technique and equipment being used, as well as the desired drilling efficiency and bit lifespan.

It is important to identify the specific requirements of the drilling project, like the desired hole size and depth, as well as the geology of the drilling site. Make use of bits that are designed for the geological conditions of the drilling site. For example, when the drilling site consists of hard rock formations, PDC or TCI diamonds mining drill bits that offer excellent penetration rates will have to be selected. Ensure that the drill bits selected are compatible with the drilling equipment, like the drill shafts and motors. Drill bits that match well with the equipment enhance drilling efficiency and reduce operational issues.

Choose mining drill bits with a proper balance between penetration rate and bit wear. While some bits may offer a high speed of penetration, they may not have the durability required for a particular drilling application. It is also important to consider the cost-effectiveness of the mining drill bits. Compare the overall costs, including bit cost, maintenance, and drilling efficiency over the life of the bits.

Q1: What are the latest trends in mining drill bits?

A1: The design and function of mining drill bits are being changed by technological advancements. Touch-screen control systems, automated down-the-hole (DTH) hammer bits, remote monitoring, predictive maintenance, and eco-friendly drill bits are all improving efficiency and production in the mines.

Q2: How are mining drill bits categorized?

A2: Mining drill bits can be categorized based on various factors. According to the material used, they can be either tungsten carbide mining drill bits or diamond mining drill bits. They can also be categorized according to their shapes, including spherical bits, taper bits, button bits, and others.

Q3: Are there any recent advancements in mining drill bit technology?

A3: Manufacturers of mining drill bits are always looking for new things to make their products stronger and last longer. Fusion bits, hybrid bits, and self-guided bits are all recent developments in the world of drill bits.

Q4: What's the future of mining drill-bit design?

A4: The future of mining drill bits will probably include bits that are more automated and environmentally friendly, as well as intelligent drill bits that can improve the effectiveness of mining operations.