All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(4175 products available)

A mini robot arm is an extremely useful and versatile gadget in the world of robotics. It can be used for multiple things in different industries like manufacturing, medicine, and research. Suppliers on Alibaba.com provide these mini robot arms in the following configurations:

Articulated Mini Robot Arms

These mini robot hands have joints similar to those in a human's arm. This makes them really flexible. They can easily do complex tasks in a small space. Factories often use them for precise work. Examples include assembling tiny parts or painting in hard-to-reach spots.

SCARA Mini Robot Arms

SCARA arms work well when tasks need horizontal movements. Their special joint design lets them move side to side smoothly. This is useful in industries like electronics. Here, components need to be put together quickly. Their speed often makes them better than the more flexible articulated arms.

Delta Mini Robot Arms

Delta arms excel at moving things fast. Their unique, parallel design enables quick handling of light objects. Many industries rely on this speed. That includes food packaging and lab testing. Delta arms improve how products are sorted or packed.

Robot Arm Kit with Grippers

Grippers can firmly hold objects of different shapes. This makes them great for tasks like putting parts together or moving items around. In factories, they help with assembly work by picking and placing components. They are also useful in warehouses. Here, they organize stacks of materials.

Robot Arm with Suckers

Suckers, or vacuum grippers, pick up flat items like sheets or boxes. They work by creating a small suction force that can lift these things. This is helpful in industries like printing. Here, paper handling is needed. They also assist in packaging by moving containers. Their design keeps lifted items safe and steady.

Robot Arm with Manual Control

These arms let users move each joint by hand. This gives the operator strong command over the arm's actions. It is ideal for tasks that need precise movements. One can use them in training or workshops where one has to understand robotics. The hands-on control is great for learning. It can also be good for small production runs with special needs.

Robot Arm with Remote Control

Remote arms carry out tasks from a distance. Users guide the arm with a remote control or computer. This is especially useful when there's a need to keep away from danger or work in tough conditions. For example, their arms help with repairs in places that are too risky for workers. This allows work to continue safely.

The materials and design of a mini robotic arm are vital parts that affect what the arm should do. These things also determine how long the arm lasts. Some of the common materials used to make these arms include:

Aluminium Alloy Components

Mini robot arms often use special aluminium alloys to make their parts. The alloys are strong but also light in weight. This helps the robotic arm move quickly and with ease. The metal alloys do not rust, so they are quite durable. One can use them for a long while without worry. They provide a mix of strength and long life.

High-Strength Steel

Some parts of the robot arm may use steel. Steel is very strong and good for areas where the arm has to carry heavy loads. However, it is heavier than other materials. This makes robotic arms with steel parts less agile. The strength of steel is best for tough tasks that need extra support.

Plastic Polymers

Certain non-load bearing parts might use plastic polymers. These plastics are light but can be strong too. They are often used for sensors or casing covers. While not as strong as metal, plastics add flexibility. This makes them good for designs with many small detailed parts.

Carbon Fiber Reinforced Polymer

The very latest mini robot arms may use carbon fiber. This material is super strong and even lighter than aluminium. It works well for high-performance arms that require the best speed and precision. Though more costly, carbon fiber provides unmatched strength for its light weight.

The design of a mini robot arm is based on what tasks it needs to do. These tasks can range from manufacturing to medical surgeries to exploring outer space. The parts that allow the arm to move include:

Joints and Degrees of Freedom

The joints let the arm move like a human arm. The more joints, the more ways it can move. This makes the arm really flexible and able to do many different tasks. However, more joints also mean the arm is harder to control and takes up more space. So manufacturers should consider what the mini arm will be used for before choosing the right joints for it.

End Effectors

End effectors are the devices attached to the robot's "hand." They help the arm complete specific tasks. Grippers, tools, and sensors are all types of end effectors. Grippers can hold items while tools let the arm carry out tasks. Sensors allow the robot to "feel" and examine things in its environment. The right end effector gives the mini robot arm the ability to perform many different jobs.

Suppliers on Alibaba.com offer mini robotic arms that buyers use in diverse industrial and commercial applications. These robotic arms are small and versatile. They automate tasks in many settings. Some of these settings are manufacturing plants, research labs, hospitals, and even educators worldwide. In fact, mini robot arms are becoming more common due to their affordability and the wide range of jobs they perform.

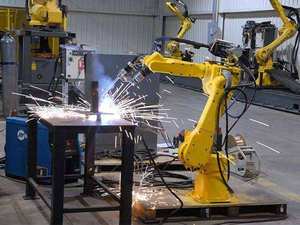

Manufacturing Automation

In factories, mini robot arms speed up production by automating tasks. They can assemble parts, paint objects, and handle materials with great precision. This boosts output and cuts labour costs. In electronics factories, for example, these robots help assemble tiny components quickly and accurately.

Quality Control

Mini robot arms come with sensors that allow them to inspect products for defects. This ensures high quality in manufacturing output. In pharmaceutical production, robotic inspection devices are essential to meet strict regulation. They help catch any issues before products reach consumers.

Packaging and Palletizing

Packaging is another key use. These small robots can sort items, pack them neatly into boxes, and stack pallets for shipping. Their speed reduces time spent on this work by hand. Many warehouses are also starting to use mini robots to keep elevated workspaces safer for human workers.

Customer Service and Retail

In retail stores, mini robot arms help customers by fetching products from shelves. They are also being tested for use in the food service sector. Here, they can prepare simple meals quickly. This will help reduce wait times for customers. As competition increases, quick service will become even more important.

Laboratory Research

Many people use mini robot arms in research labs to automate tasks like pipetting liquids. This increases accuracy and allows experiments to progress faster. They also help with repetitive tests and sample analysis. Automation boosts lab efficiency, letting scientists focus on more complex work.

Educational Tools

Schools now include mini robot arms in science classes. This gives hands-on experience with coding and robotics to students. The students easily understand how robots work by controlling the arms to complete tasks. This prepares students for future careers in tech.

Minimally Invasive Surgery

In healthcare, mini robot arms assist doctors during complex surgeries using small incisions. This leads to quicker patient recovery times compared to open surgery. They also help with precise movements while operating.

Precision Handling

These robotic arms are able to pick and move small surgical instruments. Their accuracy helps improve surgical outcomes. Hospitals are keen to adopt these technologies to enhance patient care and safety.

One has to think about many factors before selecting the right mini robotic arm for one's clients. It is essential to understand the clients' operating needs and the tasks they will perform to make the right choice. Here are some key factors to consider:

Load-Bearing Capacity

It is important to assess the weight of the parts that the robotic arm will handle. One does not need to buy an arm with more strength than necessary. Doing so will waste resources. At the same time, one should avoid overloading weaker arms. This will damage them. A proper evaluation of load-bearing capacity will ensure great performance.

Workspace

The workspace of the robotic arm should be compatible with the target workstation. Robotic arms come in differing lengths and widths, so selecting one that fits the working area is critical. Moreover, if the arm has to perform multiple tasks, buy extensions for its workspace. This will allow it to be useful for more tasks.

End Effectors

End effectors are vital for the robotic arm to perform its task. After all, effectors are the parts that go on the arm. They can be grippers, suckers, or special tools. Therefore, ensure the right end effector is fitted for the task at hand. Also, remember that some robotic arms allow for easy swapping of effectors. This adds versatility to the arm.

Control Systems

A smooth control system will be needed for proper operation. There are three common methods of control for robotic arms. The first is by hand, which gives full command over the arm. The second is remote control, which provides some range of motion. The last is computer-based, which allows automation for more extensive operations. The choice will depend on the clients' needs and resources.

Precision and Repeatability

Robotic arms are generally used in tasks that need a high degree of accuracy. As in manufacturing and surgery, the arm must be able to place an item in precisely the same spot every time. Therefore, check the arm's precision ratings. These numbers will help indicate the arm's level of repeatability. Always prioritise accuracy when selecting a robotic arm.

A1. It mainly uses metal alloys like aluminium and steel. However, it can also have parts made from strong plastics and carbon fibre composites. These materials are light but strong. They enable the robotic arms to move readily while bearing sufficient load.

A2. These robotic arms work well for light to medium jobs in many areas. In fact, manufacturers use them for assembling and packing goods. The arms can help handle inventory in warehouses. After all, their small size enables them to operate in tight quarters. Hospitals also use them during delicate surgery. Researchers like to use them for lab experiments. They are also widely employed for training in schools. Their versatility makes them applicable for various commercial and industrial uses.

A3. Regular cleaning with gentle wipes will remove any dirt or dust. That will prevent build-up on its joints and effectors. Taking clients' frequent inspections and lubricating key moving parts with a suitable oil will keep it running smoothly. That will also reduce friction and wear. Moreover, ensure one does not overload the arm or exert extreme forces on it. Doing this will prevent damage to individual components. Clients will also benefit from regular software updates. They improve performance and security.

A4. It is easy to set up most mini robot arms as they come with clear directions. Users may have to mount a few parts and wire in the electrical components. The programming is also simple. Many arms use popular coding languages. Some even come with their own graphical coding interface. This makes programming easy for beginners.

A5. Though small in size, many mini robots can lift several pounds. Their precise movements enable them to handle delicate items with care. For durability, they commonly make them with metal parts that don't rust. Moreover, some have protective covers to shield them from damage. So, clients can trust that these mini robots will last several years.