(782 products available)

A milk analyzer instrument is a device used to test milk for various compounds and properties. There are mainly two categories of milk analyzer instruments: chemical-based analyzers and chemical-based analyzers.

Optical-based analyzers:

Optical analyzers use light interaction with milk to determine its components. They typically employ a light source that transmits light through a sample of milk. The way this light is absorbed, scattered, and transmitted gives insight into the chemical makeup of the milk. Common variables that optical analyzers may measure include the concentration of fat, protein, lactose, and the presence of contaminants. The advantages of optical-based analyzers are that they offer non-destructive testing, rapid results, and high-throughput capabilities.

Chemical-based analyzers:

Based on the interaction of chemical reactions with milk, chemical analyzers determine the components by measuring the reactions that take place when milk interacts with specific chemicals. Such reactions may involve changes in color, pH, or conductivity, which are indicators of particular milk compounds. For example, chemical analyzers might use titration methods or indicator dyes to determine fat or protein content. While chemical analyzers may offer precise results, their downside includes time-consuming processes, limited sample sizes, and potential material handling issues.

Colloidal milk analyzer instruments:

Colloidal milk analyzers are designed to analyze the characteristics of milk as a colloidal suspension. Milk is a complex fluid containing fat globules, proteins, lactose, and minerals dispersed in water. Colloidal milk analyzer instruments help determine the stability, viscosity, and particle size distribution of the milk sample. These parameters are essential for assessing the quality and consistency of milk and its suitability for various applications, including dairy product formulation and processing. Colloidal milk analyzers employ techniques such as light scattering, rheometry, and electroacoustic sensing to provide detailed information about the colloidal structure of milk. The devices offer precise measurements and usually have advanced data analysis capabilities.

Wet chemistry milk analyzer instruments:

Wet chemistry methods for analyzing milk involve carrying out chemical reactions on milk samples to determine the concentration of specific components. These methods make use of chemical titrations, colorimetry, and reagent-based assays to measure the levels of substances such as fat, protein, lactose, and vitamins in the milk. While wet chemistry methods provide accurate and reliable results, they have some major disadvantages, including high sample volume requirements, labor-intensive processes, and limited automation capabilities compared to other analytical techniques.

Specifications for milk analyzer instruments will vary depending on the type and model of the machine. Some of the more common specifications include the following:

For accurate and reliable results, proper cleaning and maintenance of milk analyzer instruments is very crucial. Here are some general maintenance and cleaning tips:

Milk analyzer instruments have various use case scenarios in the dairy industry as well as others. They are versatile and valuable pieces of tools essential in ensuring milk quality is determined accurately and promptly.

The first usage application is in-dairy farms. Farmers can utilize the milk analyzer to analyze the quality of milk as well as its composition on-site before the milk gets processed or distributed to other markets. Conducting the test while still on the farm helps in making immediate decisions concerning the health status of the dairy animals. It also helps the farmer know whether the milk is fit for processing or not.

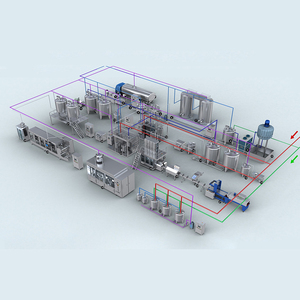

The second usage application is in milk-processing plants. Here, the milk analyzer is used for the quality control of milk and any dairy product during processing. Analyzers with automatic features help in streamlining the process of analyzing. They also improve efficiency within the plant. The instrument can monitor the composition of milk, which includes protein, fat, and lactose levels. It can also detect any adulterants present in the milk.

Milk analyzer instruments can also be used by regulatory agencies to ensure consumers are protected against substandard products. The agencies can use the instrument to analyze the quality of milk and dairy products sold to consumers. They can check for any contaminants or adulterants to ensure the milk complies with set standards and regulations. Also, the milk analyzer can be used by independent testing laboratories. After dairy farmers or processing plants take samples of their products for further testing, the independent laboratories can use the milk analyzer to determine the composition and quality of the dairy products with precision.

Lastly, education and research institutions can use the milk analyzer instrument for instructional purposes. They can also use it for research to improve the dairy industry.

Dairy farmers and businesses need to select the right milk testing instruments to ensure quality control and compliance with industry standards. Here are several tips and important factors when choosing milk analyzer instruments.

First, one should consider the accuracy and precision of the analyzer. While looking at different options, it is important to choose an analyzer that offers high accuracy and reliable results. The chosen device should have a proven track record and certified standard to ensure the results can be relied upon.

Second, choose a versatile milk analyzer that can perform multiple tasks. As discussed above, there are different types of milk analyzers, each with its own distinct capability. Opt for an analyzer that can test for different components, such as fat, protein, lactose, and added water. This will help eliminate the need to purchase additional analyzers for different tests.

Fourth, the analyzer's maintenance requirements and associated costs should be considered. Some high-end analyzers may have delicate parts that require regular maintenance. Opt for analyzers that can be maintained easily and have lower costs to help reduce overall expenses.

Lastly, consider the training required to operate the analyzer. Some milk analyzers are automated and are very easy to use. Others may have complex systems that require specialized training. Choose an analyzer that is easy to operate and understand to help reduce training costs and time.

Q1. How does a milk analyzer work?

A1. Modern milk analyzers work based on chemical and physical property testing, and the technology used in each may vary. Here are some common ways milk analyzers work:

Q2. What are the benefits of using a milk analyzer?

A2. The milk analyzer brings several benefits to users. First, it improves efficiency and productivity. Using a milk analyzer can help users analyze milk samples faster and thus improve operating efficiency. Second, it offers accurate results. Milk analyzers usually employ advanced technology and precise measurement methods, offering users accurate and reliable analytical data. Third, it may assist with quality control. Thanks to the analyzer, users can monitor the milk quality and composition continuously and promptly, thus ensuring the product's quality.

Q3. What are the limitations of milk analyzers?

A3. Different types of milk analyzers have some limitations. For example, some models may be only suitable for specific milk types, such as fresh milk, raw milk, or milk containing additives. In addition, some milk analyzers may require users to preprocess milk samples before testing, such as dilution, which is time-consuming and may introduce errors.