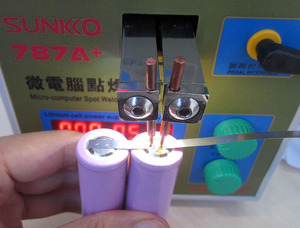

Introduction to Micro Computer Spot Welding Machine

A micro computer spot welding machine is a state-of-the-art tool widely employed in various industries for precise soldering applications. This compact device utilizes an advanced microcomputer for enhanced control and accuracy, ensuring that every welding task is completed with utmost efficiency. Whether you're in the automotive sector, manufacturing, or electronics, this machine caters to all your spot welding needs with reliability and finesse.

Types of Micro Computer Spot Welding Machines

Micro computer spot welding machines come in several types, each designed to cater to distinct requirements. Here are some prevalent categories:

- Portable Micro Computer Spot Welding Machines: Ideal for fieldwork or repair tasks, these machines are lightweight and easy to transport.

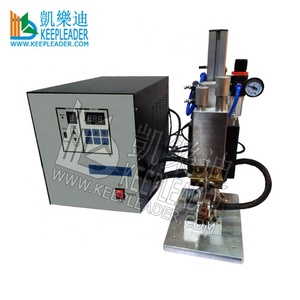

- Desktop Micro Computer Spot Welding Machines: Perfect for use in production facilities where space and permanence are key factors, offering greater stability.

- Automated Micro Computer Spot Welding Machines: These machines are programmed for high-volume manufacturing tasks, delivering consistent results at an unparalleled speed.

- Battery-Powered Micro Computer Spot Welding Machines: A convenient option for workers needing mobility without sacrificing performance, suited for remote operations.

Applications of Micro Computer Spot Welding Machines

Micro computer spot welding machines find utility across diverse sectors. Here are some common applications:

- Automotive Industry: Used for welding thin metals and components in vehicle assembly, ensuring durability and longevity.

- Electronics Manufacturing: Ideal for attaching connectors and components on circuit boards with precision.

- Aerospace Engineering: Critical in joining materials that require compliance with stringent safety standards.

- Jewelry Making: Perfect for delicate operations where accuracy is vital to achieve the desired design integrity.

Advantages of Micro Computer Spot Welding Machines

Investing in a microcomputer spot welding machine comes with numerous advantages:

- Precision and Consistency: The microcomputer controls the welding parameters, resulting in consistent weld quality across every operation.

- Energy Efficiency: These machines consume less power than traditional welders, making them cost-effective in the long run.

- Ease of Use: User-friendly interfaces and programmable settings allow operators, regardless of their skill level, to achieve professional results.

- Adaptability: With adjustable settings, these machines can handle various materials and thicknesses, making them versatile tools for different applications.