All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(8301 products available)

Metal shredder blades are crucial components of metal shredders. They are primarily used to cut or shred various types of metal waste, such as used pipes, cans, plates, barrels, and electronic waste. Different types of metal shredder blades are suitable for distinct specifications and applications of metal shredders.

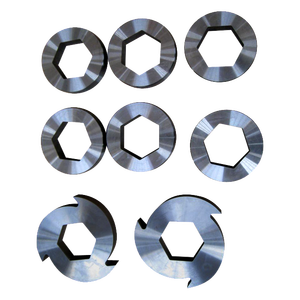

The shredder blades can be divided into two primary categories based on their shape and design: single-shaft blades and multi-shaft blades.

Single-shaft blades:

Single-shaft shredders typically have a rotor with helical or straight blade rows. The rotor is driven by the power of the motor to rotate and cut the materials against the fixed blades. The shredding mechanism of single-shaft blades is simple, and they are suitable for shredding soft metals and plastic materials.

Multi-shaft blades:

Multi-shaft shredders comprise a fixed number of rotating shafts and are more complex than single-shaft blades. Multi-shaft shredders typically have three to ten shafts equipped with shredder blades. The shredding method is realized by the rotating blades and the gap between the blades. Multi-shaft blades can shred various materials, such as hard metals and mixed metal waste, and have higher productivity and efficiency.

Based on their functionalities, metal shredder blades can also be categorized into three primary types: piercing blades, stripping blades, and flat blades.

Piercing blades:

Piercing blades (also known as anchor blades) are designed to pierce and grab materials. They are usually placed in the first feeding section of a shredder. The geometry of piercing blades allows them to penetrate the bulk materials, increasing the mixing and movement of other unshredded materials. As a result, more materials can be fed into the shredding chamber, which improves the shredding efficiency significantly.

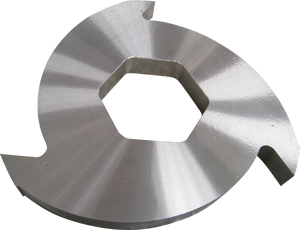

Stripping blades:

Stripping blades are also known as claw blades. They are commonly used in mid to later stages of shredding. The geometry of stripping blades is similar to claws, which can grasp and strip materials off other unshredded materials. Compared to piercing blades, stripping blades have a better role in reducing the size of materials and further preparing unshredded materials for the subsequent shredding process.

Flat blades:

Flat blades are commonly used in rotary crushers. They have a flat surface to crush and homogenize unshredded materials. The flat geometry provides a larger surface area, which can further confine, trap, and crush materials. Flat blades are ideal for producing uniform particle sizes.

Specifications for metal shredder blades vary depending on the machine models they are designed to fit. Here are some common specifications:

The scheduled maintenance of shredder blades is very important. It helps to increase the lifespan of the blades, ensures they work optimally, and reduces the occurrence of unexpected breakdowns. Here are some simple maintenance tips:

Metal shredder blades perform an essential function at various industrial facilities and recycling plants. They are integral parts of machines used to shred many types of waste, such as packaging materials, scrap metal, and e-waste.

Two common usage scenarios for metal shredder blades include:

Other usage scenarios in addition to the above include:

When choosing metal shredder blades, it's crucial to consider the types of materials the machine will process. Various metals, such as aluminum, copper, stainless steel, or iron, present distinct shredding challenges. The shredder's design and construction may be well-suited for specific metal types but not for others.

Furthermore, the dimensions and weight of the materials are essential factors. Shredder blades are often customized to handle particular sizes and weights. If an invasive shredder attempts to process oversized or heavier items, it may strain the machine, leading to damage.

Production volume is another critical aspect. Fewer machines may handle small quantities but are efficient for large-scale operations. When industries shred thousands of metals regularly, they invest in powerful machines that can handle high volumes.

The required output also plays a vital role in selecting a shredder machine. Some machines produce a coarser output suitable for further processing, while others create fine, homogeneous particles ready for sale. The desired purity level is also significant. Shredders that mix different metals incur extra costs to separate and purify the final product.

The blade material and geometry are essential considerations. Shredder blades are typically made of high-carbon steel, wear-resistant steel, alloy steel, or specialized steel with impurities to improve durability. The geometry of the blades varies depending on the design, with some having straight blades, curved blades, or a combination of both.

Finally, the machine's capacity is determined in tons per hour, and the energy requirements range from small industrial-scale machines that use kWh to large-scale machines that run on diesel or natural gas. More giant metal shredders machines are typically housed outside at recycling plants and operate continuously for several years without interruptions.

Q1: How to refurbish metal shredder blades?

A1: The best way to refurbish metal shredder blades is to recycle them through a metal recycling facility. Many local facilities offer this shredded metal blade recycling service; some even have pick-up services for the abandoned machinery parts.

Q2: Are used metal shredder blades for sale?

A2: Depending on the condition, many used metal shredder blades are still for sale on various online marketplaces but are usually sold in bulk, like 50 or 100 pieces at a time, to smaller buyers or sellers.

Q3: How to tell if metal shredder blades are worn out?

A3: The signs of worn-out metal shredder blades are obvious cutting edges, excessive noise during shredding, a change in the texture of shred materials, increased power consumption, vibration, and elongation of the shredder blades, among others.

Q4: Can businesses customize their metal shredder blades?

A4: Many metal shredder blade suppliers offer various customizing options for businesses to choose from when it comes to design, material, size, etc.