All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(50 products available)

The metal oxide varistor 20D471K is a common component in electrical systems, protecting against voltage surges. Though this device is usually found in many commercial and industrial devices, people make distinct types to meet specific needs.

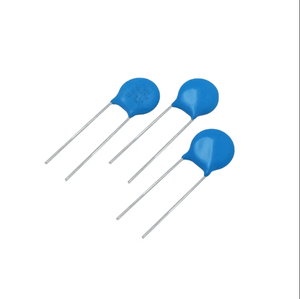

Ceramic varistors: These varistors are one of the most common types. They comprise a ceramic material with metal oxides embedded within. Ceramic varistors are popular and widely deployed because they have a good surge protection capacity. They protect frequently exposed electrical systems like power lines and outlets.

Disk varistors: Disk varistors are one of the types of ceramic varistors. People design varistors to handle more power. Because of this, disk varistors are more frequently deployed in industrial settings where raw supply lines may carry irregular voltages. Even though they are larger than regular ceramic varistors, they can still handle more power voltage surges.

Surface Mount Varistors (SMDs): As the demand for smaller electronics increases, people design varistors to meet this demand. Surface mount varistors are smaller, making them easier to deploy in compact electronics like cell phones and computers. They give protection while taking minimal space. However, these varistors cannot handle the same high surge power as their larger counterparts.

Hybrid Varistors: For protection, these varistors combine multiple surge protection technology features. For example, a hybrid varistor may have ceramic materials and electrical circuitry within it. The circuitry helps control how and when the varistor functions. Hybrid varistors are most frequently installed in new electronics that need customized surge protection features.

Temperature coefficient Varistors: Temperature coefficient varistors are a special varistor type. People design these varistors to account for temperature changes. When the temperature increases, these varistors help voltage surges that would usually be accompanied by temperature increases. They do this by changing how much voltage they allow through as temperatures increase. The varistors are useful in situations where voltage surges will frequently be accompanied by increased temperatures, such as inside appliances or heavy electrical motors.

Metal varistor devices consist of several parts, each contributing to how the device operates to safeguard an electrical system. Understanding the key materials and components makes up the varistor's internal structure. The voltage surge affecting an electrical system helps find the proper varistor.

Metal oxide grain: The grain, the main part of a varistor, is usually made from zinc oxide and sometimes other metal compounds. When voltage surges come through the device, this grain material allows the excess voltage to spread out rather than overloading the system. The zinc oxide grains fill a ceramic matrix. It gives the varistor its unique surge protection properties.

Ceramic binder: Varistors use a ceramic-like material to hold the metal oxide grains in place. Manufacturers use this ceramic binder when constructing varistors. They usually use it in combination with the metal oxide grains. The binder supports and insulates the grains so that they can effectively safeguard against surges. When surges appear, the ceramic material helps distribute power evenly across the grains.

Electrodes: Varistor manufacturers construct electrodes from conductive metals like silver-plated copper or aluminum. These electrodes attach to the grains and binder inside the varistor. Varistor electrodes have two metal plates on the outside called electrodes. The electrical current first passes through one electrode, spreads through the inner material, and finally exits through the second electrode.

Protective coating: To ensure the varistor functions properly, manufacturers frequently add a protective outer coating. Plastic, epoxy, or resin coatings insulate electrical current. They also physically protect fragile components from moisture and other harm. Without this coating, voltage surges would more frequently damage the varistor itself.

Internal wiring: There are internal wires or connections within the varistor that link the electrodes to the internal ceramic and metallic materials. Usually, manufacturers connect these wires to conduct the electrical current as the surge passes through. The wiring enables smooth energy flow between all parts.

The varistor 20D471K is a vital part of many electrical devices. It is commonly used in surge protection circuits found in many appliances, computers, and industrial systems. It protects the devices from voltage spikes, improving their reliability and lifespan. In power supply systems, manufacturers install the varistor in transformers and power distribution units. This helps stabilize voltage levels and keeps the systems running smoothly, even during fluctuations. In automotive electronics, the varistor protects sensitive components from electrical noise and spikes.

Manufacturers use this Varistor in electrical devices like TVs, audio equipment, and gaming consoles. The varistor protects these devices from power surges or noise on electrical lines. It ensures the devices work well without interference.

The metal varistor is sometimes installed in induction motors. The varistor protects the motor control system from voltage surges created during motor operation. This keeps the system stable and prevents damage. This varistor also finds its way to light dimmers and LED drivers. It provides surge protection and stabilizes voltage fluctuation in lighting systems. Overall, any electrical or electronic device exposed to power surges or fluctuations will sometimes contain this varistor. It ensures consistent surge protection.

The varistor durability depends on several external factors. Notable among them is temperature. Extreme temperatures can damage metals and ceramics inside a varistor. Excess heat from devices or the environment can degrade the materials over time. Design factors like the varistor's internal construction also affect durability. Varistors with better materials or designs to spread out surges more evenly tend to degrade less.

Constant voltage surges or prolonged exposure to excess voltage can wear out a varistor faster. Manufacturers design varistors to handle a specific range of voltages. Exceeding this range too often will reduce longevity. User installation mistakes reduce durability. Mounting a varistor improperly in electronic equipment causes excess strain. Improper wiring also subjects the varistor to unusual power levels.

Operating conditions like humidity and dust indoors play a role. Moisture or particulate matter damage the protective coatings or infect the internal materials. Regular industrial environments exposed to chemicals or high moisture levels have shorter varistor lifespans. Lastly, electromagnetic interference from nearby high-power devices can induce surges in the varistor. Such surges would overwhelm the varistor power capability and lead to premature failure.

The 20D471K varistor features a voltage rating of 380V in direct current and a maximum continuous AC voltage input of 265 volts. Its surge rating allows it to handle brief voltage spikes of up to 20,000 volts, which is essential for protecting circuits from surges. The varistor has a maximum clamping voltage of 5468 volts. The device's response time is less than 25 nanoseconds, ensuring it activates quickly during a surge.

The varistor also has an energy absorption capability of 66 joules. This rating measures the total energy it can safely dissipate during voltage spikes. The varistor is reliable and has a failure mode designed to short-circuit it. This failure mode prevents it from becoming unsafe in case of imminent failure.

Key features of the varistor include excellent surge protection and robust voltage handling capability. It also has minimal size and effect on the circuit during regular operation, making it useful in compact electronic designs. The varistor is ideal for devices that need protection from high-energy voltage spikes, such as power supply circuits and industrial control equipment. People frequently use the varistor in consumer electronics, automotive applications, and telecommunications equipment.

A1: Varistors protect circuits by changing their electrical resistance in response to a voltage change. So, when the voltage is at a normal range, the resistance is high. This situation prevents any small voltage from going to the circuit. But when the voltage experiences a surge, the resistance also decreases. The excess voltage then passes through the varistor to clamp the surge.

A2: Manufacturers usually install it in power supply circuits, which commonly experience voltage fluctuations. They also use them in industrial control systems where power surges are common. In addition, people use them in telecommunications equipment to protect against voltage spikes on data lines.

A3: Yes, varistors occasionally do not stop absorbing surges. Instead, they continue doing so until the absorbed energy exceeds their threshold capacity. At this point, the metal oxides within the varistor may experience breakdown. It is no longer able to protect the circuit from surges. This is commonly known as failure. Manufacturers rate every varistor's max energy absorption capacity tolerates.

A4: No, varistors do not need regular maintenance. However, directly monitoring the circuit's voltage levels will suffice. If they exceed the varistor threshold capacity, it is crucial to take action. This helps avoid damaging the equipment in the circuit.

A5: No, it is not advisable to continuously operate varistors at the maximum voltage rating. Doing so may decrease their surge protection capability over time. It is beneficial to keep the voltage within the specified range to ensure long-term reliable protection.