All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(2405 products available)

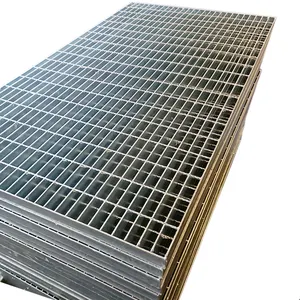

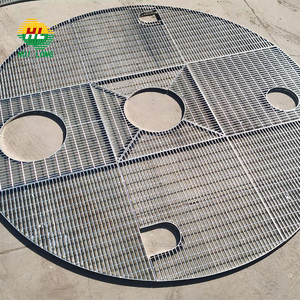

Metal grate decking, also known as metal grate flooring or deck grating, is a type of flooring that consists of grids or mesh laid on the deck. These grids are capable of allowing the passage of light, air, and water. The metal grate deck is a non-slip and durable surface that can be used in various applications and industries.

Metal grate decking comes in various types and styles depending on the application and use. Some of the popular types of metal grate decking are listed below:

Rectangular Gratings: They have flat and rectangular-shaped bearing bars. This type of grating is economical and lightweight.

Non-Slip Gratings: These grating have serrated or ribbed bearing bars. They provide excellent slip resistance and are usually used in areas where safety is important.

Square Grating: They are made of square-shaped bearing bars set in a square pattern. They offer a modern look and high strength.

Metal grate decking is used in construction for enhancing safety and durability. Its features offer several advantages when used in construction. Some of them include:

High strength and load-bearing capacity

Metal grates are made from different alloys that are used in construction. This includes; carbon steel, galvanized steel, aluminum, and decorative stainless steel. These metals have high tensile strength. This makes them capable of withstanding heavy loads and high traffic. They are used in applications where structural integrity is important. This includes; walkways, balconies, docks, and industrial platforms.

Slip-resistant surface

Metal grates have patterns and textures. For example, checker patterns, ribbed, or serrated textures. These increase friction and reduce the risk of slipping. They provide a safe surface for walking. It protects pedestrians from falling or accidents caused by slippery surfaces. Metal deck grates are used in high-traffic areas. They can also be used in residential decks and patios.

Drainage and airflow

Metal grates have open spaces between the bars. This allows water to flow through and air to circulate. Good airflow prevents the accumulation of moisture. It keeps the deck surface dry. The open design of metal decking helps in effective water management. It prevents water pooling and reduces the risk of corrosion. This is important for decks in areas with heavy rain or snowfall.

Low maintenance

Metal decking requires little cleaning and maintenance. This is because they have smooth surfaces. They are resistant to rot and insect damage. They also withstand harsh weather conditions. The metal grates are resistant to rust, especially the galvanized and aluminum grates. They are popular among homeowners because they save time and money in the long run.

Customizable designs

Metal grates come in different sizes, shapes, and patterns. This allows engineers and architects to choose metal deck grates that fit their design specifications and functional requirements. Some metal grates can be painted or coated with different finishes. This improves aesthetics and enhances slip resistance.

Metal grate decking, especially in the form of steel grates, has diverse applications across various industries and sectors. Here are some common usage scenarios:

Construction and Building

Metal grate decking is widely used in the construction of walkways, catwalks, and platforms. This is for its high strength and load-bearing capacity. They are also used in stair treads, drainage covers, and parking structures.

Industrial and Manufacturing Facilities

They are used for floor grating in industrial plants and factories. This allows for easy spillage cleanup and lightweight transportation. Metal grate deckings are also used in oil and gas facilities, power plants, and chemical processing plants. This is due to their slip-resistant surface and high ventilation properties.

Commercial and Retail Spaces

Metal grate decking is used in commercial buildings, shopping malls, and supermarkets. This is to construct walkways, ramps, and loading docks. Their durable nature and ability to withstand high foot traffic make them an ideal choice for these settings.

Recreational Areas and Public Spaces

These metal deck planks are perfect for pedestrian bridges, public plazas, and outdoor staircases. They combine functionality with aesthetic appeal, making them suitable for both urban and natural environments.

Aerospace and Aviation

In the aviation industry, metal grate decking is used in aircraft hangars, maintenance facilities, and taxiways. Their strength, durability, and drainage capabilities make them ideal for high-traffic areas in airports.

Marine and Maritime

They are utilized in shipbuilding, port facilities, and offshore structures. This is because they offer slip resistance, drainage, and high-strength features. Metal grate deckings are also used in marinas and docking stations.

Utilities and Infrastructure

These metal decking grids are perfect for substations, transformer stations, and utility vaults. This ensures worker safety and equipment protection. They are also used in water treatment plants and sewage facilities.

HVAC Systems

Metal grate decking is used as air vents or register covers in heating, ventilation, and air conditioning systems. The open-grid design allows for efficient airflow while ensuring durability and strength.

Food and Beverage Industry

These metal decking boards can be sanitized easily, making them suitable for food processing plants, kitchens, and breweries. They are also used in coolers, freezers, and storage areas.

Healthcare and Pharmaceutical

Metal grate deckings are used in hospitals, clinics, and laboratories. This is to construct walkways, ramps, and sterile areas. They are easy to clean and maintain, ensuring hygienic environments.

Farm and Agriculture

They are used in animal enclosures, barns, and storage sheds in agricultural settings. The open-grid design allows for easy waste management and animal health.

When choosing metal grate decking for a particular application, there are several factors to consider. These factors are discussed below.

Load bearing capacity

Each metal grid decking has a different load capacity. It is important to consider the expected load and select a decking option that can support it. Heavy duty options are available for industrial areas with high traffic flow and heavy machinery. While lighter gauge options are suitable for pedestrian walkways and terraces.

Slip resistance

Safety should be a priority when selecting metal grate decking for areas that are exposed to water or moisture. Slip resistant decking should be considered to avoid accidents. Slip resistant decking has grooves or textured surfaces that offer better traction.

Material durability

Metal grate decking comes with different materials. Each of them has different characteristics and advantages. Aluminum is lightweight and does not rust. It is a good choice for coastal areas. Steel grating is more durable and is available in galvanized or powder coated finishes to enhance its corrosion resistance. Stainless steel offers the best corrosion resistance and is suitable for high-end applications.

Maintenance requirements

The maintenance level required depends on the material and location of the decking. Aluminum and stainless steel grates require minimal maintenance. While galvanized steel grates may need periodic cleaning and re-coating to prevent rust.

Aesthetic appearance

Metal grates come in different patterns and finishes. This makes it possible to select an option that complements the architecture of a building. Consideration should be given to the visual appeal of the decking. Especially for residential applications and outdoor living spaces.

Ease of installation

Some metal grates may require specialized welding equipment for installation. While others can be installed easily using simple tools. It is good to consider the installation method and associated costs.

Q: What are the advantages of grate metal decking over traditional solid decking?

A: The major benefit of metal grate decking is that it allows water to flow through, keeping the deck surface drier and reducing mildew and mold growth. The airflow also allows sunlight to reach plants below. Because it's not solid, it uses fewer materials, making it more eco-friendly. The ventilation gaps reduce wind and storm debris, requiring less cleaning.

Q: What metals are commonly used for grate metal decking?

A: Grates are usually made from galvanized steel, aluminum, or stainless steel. Galvanized steel is popular because it's durable and budget-friendly. Aluminum is lightweight and won't rust, making it good for coastal areas. Stainless steel has a sleek look and resists corrosion but costs more.

Q: How does one install grate metal decking?

A: Installation involves securing the grates to the subframe using welds or decking screws. It's important to line up the grates evenly and leave proper expansion gaps. Installation may differ between welded or screwed grates, so following the provided instructions is essential.

Q: How does one maintain grate metal decking?

A: Maintenance is straightforward. Simply sweep away debris and rinse off the deck with water as needed to prevent grime buildup. In coastal areas, users should regularly check for salt deposits and rinse with fresh water. They should also inspect for loose screws or signs of corrosion and tighten or treat as needed.

Q: What load can grate metal decking support?

A: The load capacity depends on the grate design and spacing. Close-spaced grates can support heavier loads. Most residential decks are designed for live loads of 40 pounds per square foot. This takes into account people, furniture, and plants. Always check local codes for specific load requirements.